Skylar

Well-known member

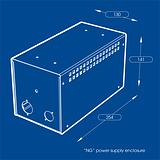

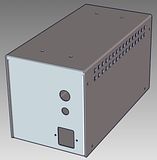

I am designing an enclosure for a tube microphone power supply.

The design follows the feel of the EQU47 mic body from this thread and is heavily influenced by the Neumann NG-series power supplies.

I would like to offer this power supply for sale to groupdiy members.

DETAILS:

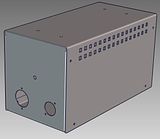

The enclosure is a two-piece "U" design to be made from folded sheet metal (20–22 gauge steel).

The dimensions are W=5.12"(130mm) x H=5.56"(141mm) x D=10"(254mm)

The plan is to leave the metal unfinished so that you can finish it in any colour you like.

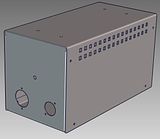

Front:

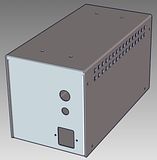

Back:

The enclosure cover attaches to the base with 8 x 6-32 screws.

The above renders have hole cut-outs for:

[FRONT]

Binder 691 7-pin female panel mount connector

neutrik XLR

1/4" (6.35mm) pot shaft

[BACK]

IEC power inlet

0.48" (12mm) toggle switch

0.69" (17.5mm) amp jewel/lamp

[TOP]

amp handle(4 holes) - 1.875" (47.5mm) centers | 7.25" (184mm) handle length

This question is thus:

What hole configuration would be most universal for this power supply?

We probably want to keep the IEC, neutrik, knob shaft, & amp handle holes as is.

Then perhaps have smaller "starter" holes for the toggle, lamp, & multipin connector holes.

What is the popular opinion on this?

Please let me know as soon as possible because my supplier is going to be asking about this soon (as in the next couple of days).

The design follows the feel of the EQU47 mic body from this thread and is heavily influenced by the Neumann NG-series power supplies.

I would like to offer this power supply for sale to groupdiy members.

DETAILS:

The enclosure is a two-piece "U" design to be made from folded sheet metal (20–22 gauge steel).

The dimensions are W=5.12"(130mm) x H=5.56"(141mm) x D=10"(254mm)

The plan is to leave the metal unfinished so that you can finish it in any colour you like.

Front:

Back:

The enclosure cover attaches to the base with 8 x 6-32 screws.

The above renders have hole cut-outs for:

[FRONT]

Binder 691 7-pin female panel mount connector

neutrik XLR

1/4" (6.35mm) pot shaft

[BACK]

IEC power inlet

0.48" (12mm) toggle switch

0.69" (17.5mm) amp jewel/lamp

[TOP]

amp handle(4 holes) - 1.875" (47.5mm) centers | 7.25" (184mm) handle length

This question is thus:

What hole configuration would be most universal for this power supply?

We probably want to keep the IEC, neutrik, knob shaft, & amp handle holes as is.

Then perhaps have smaller "starter" holes for the toggle, lamp, & multipin connector holes.

What is the popular opinion on this?

Please let me know as soon as possible because my supplier is going to be asking about this soon (as in the next couple of days).