You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Auratone DIY

- Thread starter DaveP

- Start date

Help Support GroupDIY Audio Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

rainton

Well-known member

rainton

Well-known member

another angle.

Even though Dave might not check this thread anymore - I gotta say thanks for finding the drivers and starting this thread!

Once I had the drivers this was one of the easiest projects and still very rewarding since these cubes do their job great!!

Even though Dave might not check this thread anymore - I gotta say thanks for finding the drivers and starting this thread!

Once I had the drivers this was one of the easiest projects and still very rewarding since these cubes do their job great!!

Attachments

rainton

Well-known member

12dbLow said:PS: Ah, same with you, rainton. Viel Erfolg

just saw - it Danke Adrian!

finished them already a while ago and always wanted to share some pics but now I finally made it

12dbLow

Well-known member

Wow, very nice! I would also have liked the look of some wood grain, but I thought chipboard is better for speakers. (Even though it might not make a difference for such a small, stiff cabinet..)

12dbLow

Well-known member

12dbLow

Well-known member

12dbLow

Well-known member

These are all very nice but I worry about the sharp edges and corners.

I rounded mine off to minimize diffraction effects as the sound tries to go around the corners on such a small cabinet.

With a 6" or thereabouts (150mm) box the wavelength is 2kHz and 1kHz half wavelength, smack dab in the critical mid-range region.

Nice to see people still pursuing this project though.

best

DaveP

I rounded mine off to minimize diffraction effects as the sound tries to go around the corners on such a small cabinet.

With a 6" or thereabouts (150mm) box the wavelength is 2kHz and 1kHz half wavelength, smack dab in the critical mid-range region.

Nice to see people still pursuing this project though.

best

DaveP

12dbLow

Well-known member

Thanks Dave,

yes it would be very interesting to hear these two designs in comparison. The originals also have sharp corners..

yes it would be very interesting to hear these two designs in comparison. The originals also have sharp corners..

Hello guys

For first, thank you for this inspirational thread.

I want to build these cubes, but my "problem" is that, there are different dimensions of auratone all over the web (and I want them to be as accurate as possible)

For example, here it says that original dimensions are 16,5x16,5x16,5cm http://audio-database.com/AURATONE/speaker/5c-v-e.html

Your dimensions are 16,5x16,5x14cm using 1,3cm wood

And here is another DIY plan that says 16,5x16,5x12,6cm using 0,9cm wood http://www.artandtechnology.com.au/audio/auraclone-cabinet-plans.pdf

So, why yours are about 1,5cm shorter than originals? Is there corner bracing in original auratones?

Also I think that originals had wool only at the back

For first, thank you for this inspirational thread.

I want to build these cubes, but my "problem" is that, there are different dimensions of auratone all over the web (and I want them to be as accurate as possible)

For example, here it says that original dimensions are 16,5x16,5x16,5cm http://audio-database.com/AURATONE/speaker/5c-v-e.html

Your dimensions are 16,5x16,5x14cm using 1,3cm wood

And here is another DIY plan that says 16,5x16,5x12,6cm using 0,9cm wood http://www.artandtechnology.com.au/audio/auraclone-cabinet-plans.pdf

So, why yours are about 1,5cm shorter than originals? Is there corner bracing in original auratones?

Also I think that originals had wool only at the back

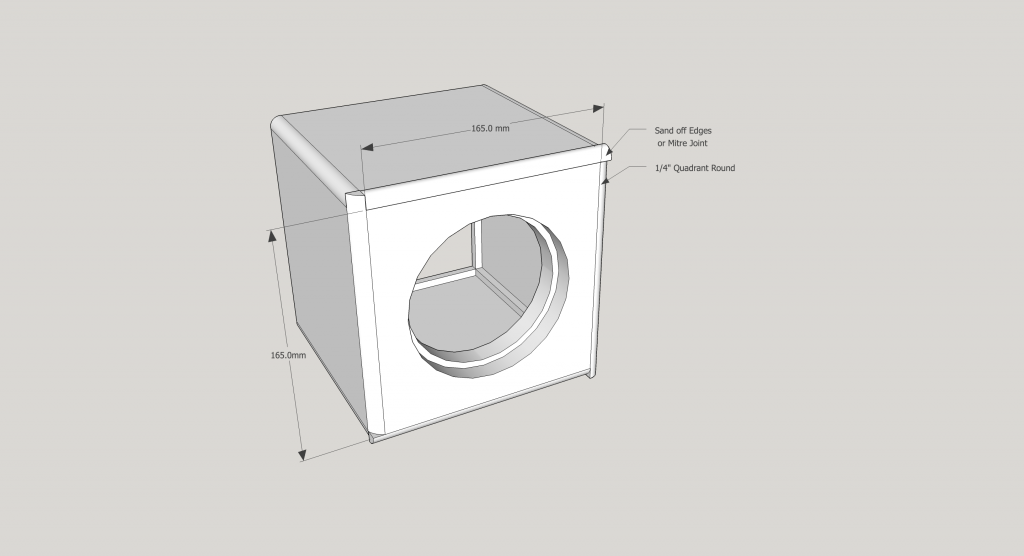

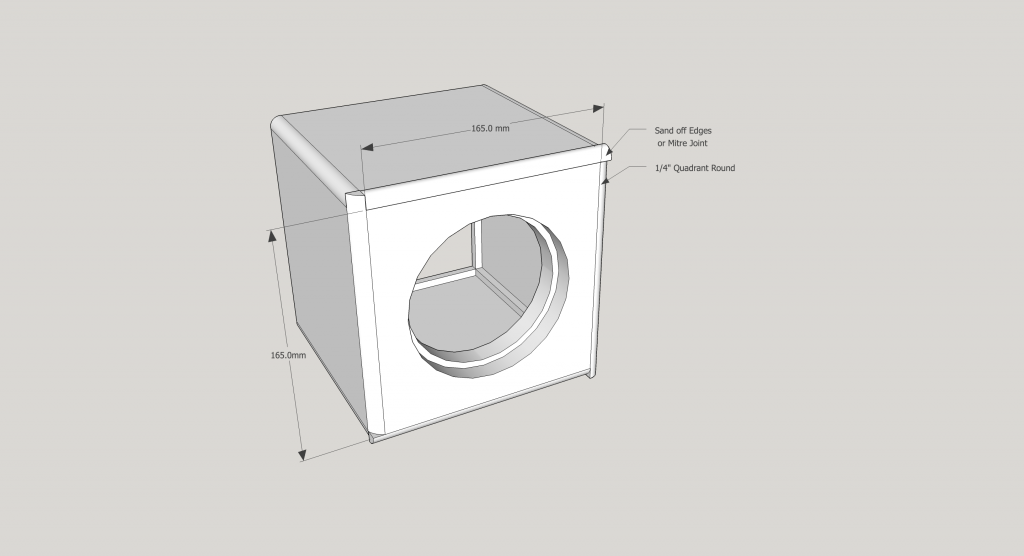

If anyone needs help on the enclosure or box side of things, here is my design

The panels fit together to leave space for quadrant round - this helps minimize baffle diffraction.

I havn't built my Davetones yet, but I have built studio monitors using the same principle.

It's all glued together with guerrilla glue and braced internally with small bits of wood. Seal with caulk and use sticky foam on the lining of the back plate to stop any air escaping.

Comes to about 2.8 Litres inside without taking into consideration the space the driver will take up. Fill with speaker insulation to increase the effective volume. You can scale down if you want a slightly smaller internal volume.

I'm using 3/4" Birch Ply as I have some spare from my last speaker build.

Thanks,

Matt.

Click the image below to view the whole album.

The panels fit together to leave space for quadrant round - this helps minimize baffle diffraction.

I havn't built my Davetones yet, but I have built studio monitors using the same principle.

It's all glued together with guerrilla glue and braced internally with small bits of wood. Seal with caulk and use sticky foam on the lining of the back plate to stop any air escaping.

Comes to about 2.8 Litres inside without taking into consideration the space the driver will take up. Fill with speaker insulation to increase the effective volume. You can scale down if you want a slightly smaller internal volume.

I'm using 3/4" Birch Ply as I have some spare from my last speaker build.

Thanks,

Matt.

Click the image below to view the whole album.

Does anyone know if there is an "online laser cut" place that will do materials appropriate for this box? How thin can I go?

I would love to build one, don't mind glueing, but don't want to mess with cutting and would like to label it with laser (1/0, cut for internal PSU, DIYoyotone... etc)

I would love to build one, don't mind glueing, but don't want to mess with cutting and would like to label it with laser (1/0, cut for internal PSU, DIYoyotone... etc)

gemini86

Well-known member

I know emachineshop.com can do laser cut mdf, don't know how thick.

Thanks, I inquired with emachineshop. I just thought it was a cute project and if we could get a file to have the parts cut, it would make it easier to pop these out. i will let you know and post files if I manage it.

update: I contacted them and the reply said "We do not work in any wood products."

update: I contacted them and the reply said "We do not work in any wood products."

I'm a little late to the party, but thought I would contribute my auratone diy results so far.

I ended up using Visaton FR 12 drivers, which I'm very happy with.

The outer box dimensions are slightly larger at 7" x 7" x 6.5".

I also used 4 pieces of 3/4" pine for bracing as suggested by others here.

I thought the cuts were pretty accurate, but when gluing together I noticed they were a little off.

It doesn't bother me too much..

I may eventually sand & paint it or get some wood vinyl covering to improve the aesthetics.

I ended up using Visaton FR 12 drivers, which I'm very happy with.

The outer box dimensions are slightly larger at 7" x 7" x 6.5".

I also used 4 pieces of 3/4" pine for bracing as suggested by others here.

I thought the cuts were pretty accurate, but when gluing together I noticed they were a little off.

It doesn't bother me too much..

I may eventually sand & paint it or get some wood vinyl covering to improve the aesthetics.

Attachments

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 4

- Views

- 2K

- Replies

- 18

- Views

- 7K

- Replies

- 372

- Views

- 66K

- Replies

- 21

- Views

- 7K