Alexandru marian

Well-known member

- Joined

- Oct 13, 2014

- Messages

- 127

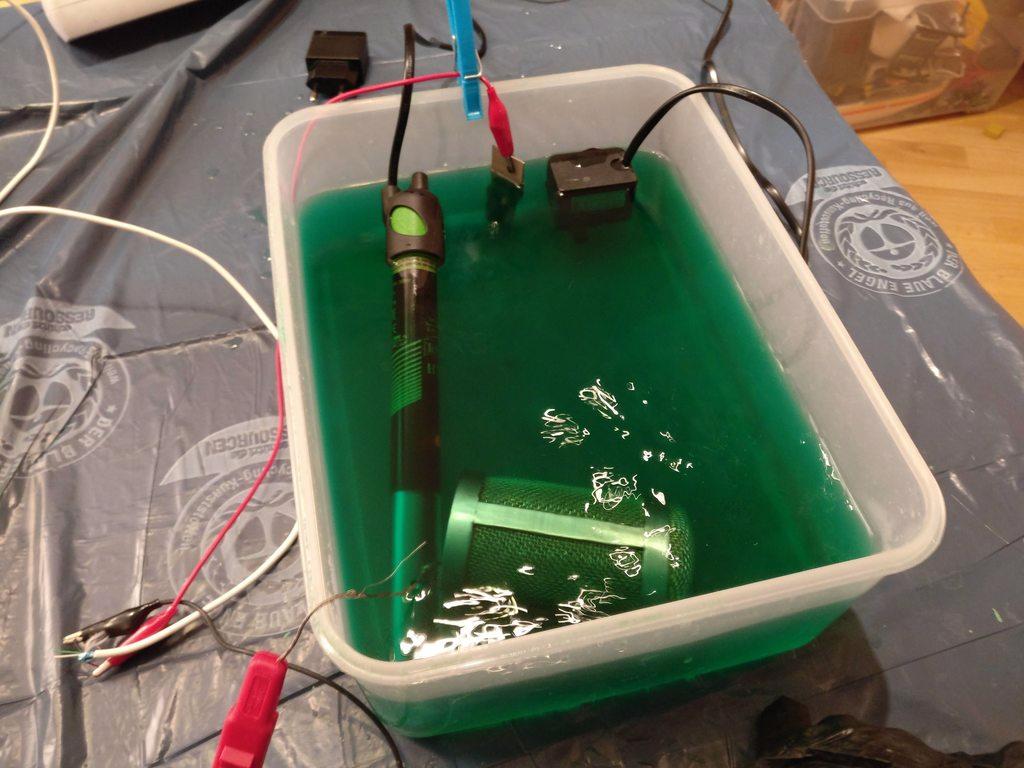

My trafo is 125VAC, goes to about 185 after the bridge.

10k dropping resistor gives 175V, 47k gives 120.

for the 120 version with everything else stock I get 66V at the tube pin 6. Center capsule is 58V at the voltage divider, pol 120/60.

for the 175V version, polarization comes from splitting the H+ after the first cap: 85k dropping resistor gives about 130/65 V, while the internal microphone divider is changed by lowering ground resistor to 300K.

These values need tweaking, 10-20k up or down if you want perfect voltages as it depends on the trafo etc. Not easy unless one buys a whole set of resistors and nice ones get pricey.

10k dropping resistor gives 175V, 47k gives 120.

for the 120 version with everything else stock I get 66V at the tube pin 6. Center capsule is 58V at the voltage divider, pol 120/60.

for the 175V version, polarization comes from splitting the H+ after the first cap: 85k dropping resistor gives about 130/65 V, while the internal microphone divider is changed by lowering ground resistor to 300K.

These values need tweaking, 10-20k up or down if you want perfect voltages as it depends on the trafo etc. Not easy unless one buys a whole set of resistors and nice ones get pricey.