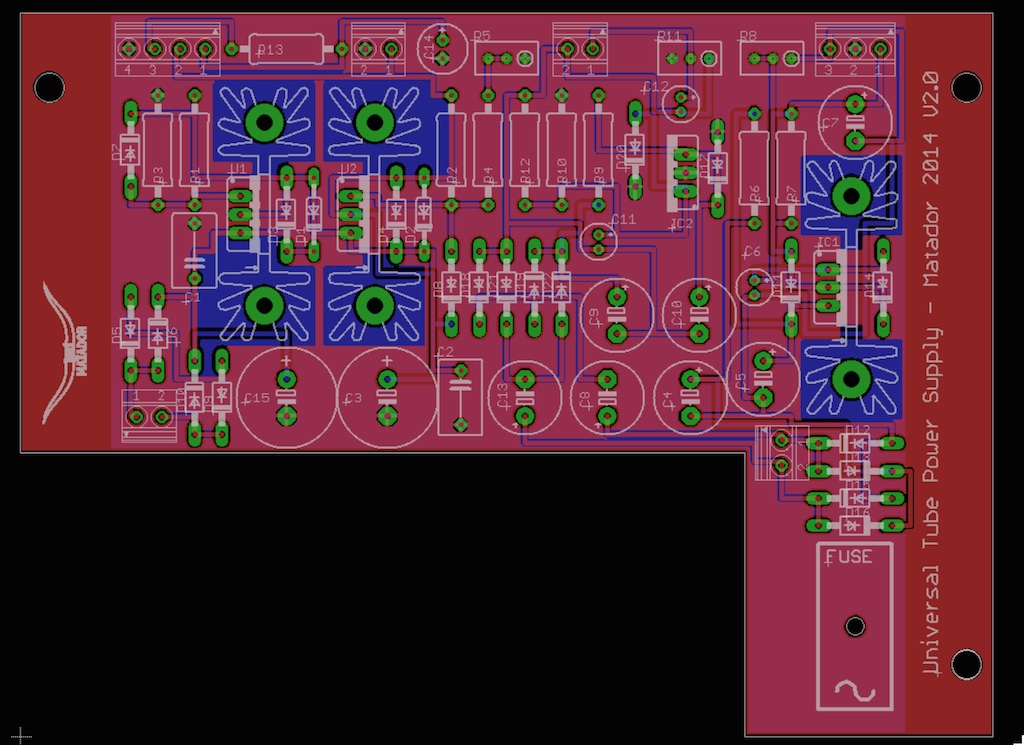

Some more news. I'll have to rev the PCB...

Problem: I really wanted this design to play nicely with the stock C12 transformer which has a 200VAC secondary. As a result, the post-rectification voltage is quite high...about 275V. At +10% line voltage, this is nearly 300V. This is above the maximum 125V input-to-output differential I quote earlier in the thread of 125V for the TL783C.

This means some of the voltage needs to be lowered via an RC filter. This works fine: for example, at 1mA load current, we can throw away say 75V, so the 300V becomes 225V, which is only 100V across the regulator worst case. So 75V at 1mA means 75 kohm. All is good.

Now what if we want more current? Let's double the load current up to 2mA. The drop across the resistor doubles up to 150V. Now we only have 150V going in to the regulator, and 120V out. So that's still fine.

What you can see if that once the load current goes above 2.4mA, then the regulator starts to drop out. We need less resistance at higher currents. This

isn't fine.

I can fix this by adding a constant "waste" current, which means that the supply gives a fixed current of about 5mA into a dummy load, and the rest goes into the tube. This is really a waste, but means that percentage wise the change from 1mA to 2mA is only a change from 5mA to 6mA, which is a much lower percentage change (20% from 100%). This I can lower the dropping resistor significantly and increasing the load current changes the output voltage much less.

It's a single added resistor to the layout. I stuffed a spare into the output of the prototypes terminals to test this and it works. It can provide up to 10mA load current @ 120V, which is enough to run a few tube stages.

I might see how much VA I can suck from this stock transformer to see if it will run MK47 tube types. 120V @ 50mA is only 6VA which I think is doable. It will just increase the stock dissipation of the PSU.

The other option is to move to a different transformer: I'm in contact with Chunger to see if that is a possibility because if so, it will greatly simplify the design.