ForthMonkey

Well-known member

ANOTHER METHOD

This is the another way to build good looking front panel.More professional!

Check this link!

http://music.codydeschenes.com/?page_id=2035

But it's not exactly what i want!I want to do it like engraved.So just leave your letters blank (or white) and the other places are black.Then try this etching method.So we can see that we have engraved looking panel.It's like making PCBs.

For me it's good idea!I will try this method with a peace of aluminum and i will share my exprience!

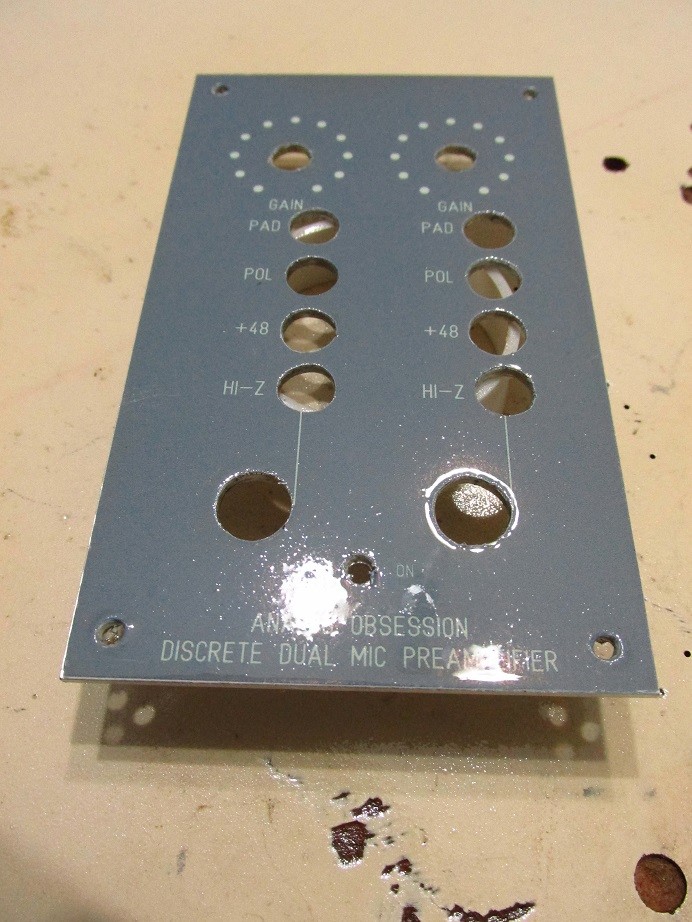

And it's an example of my front panel!

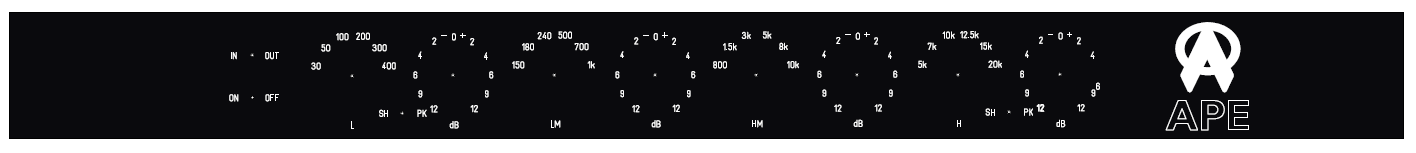

And there are lots of examples!

http://www.diystompboxes.com/smfforum/index.php?topic=85803.160

Another tutorial.

http://www.aronnelson.com/gallery/main.php/v/MarkMs-Gallery/album24/?g2_page=1

---------------------------------------

First of all,really expensive to make professional front panel for me.So i'm trying to find cheapest and easiest way to do it.

For now i used self adhesive paper for this.And some gear...

Looks good but not perfect!And little bit expensive,too!

I found another paste it to front panel with transparent glue.Then some coats of lacquer onto front panel.I belive it'll be better than self adhesive paper.I tried with some aluminum panel to see how it looks.And it's perfect!Really cheap,easy.I believe it's real DIY.

Do you have any idea to make custom front panels?Maybe cheaper or easier?

Thank.

This is the another way to build good looking front panel.More professional!

Check this link!

http://music.codydeschenes.com/?page_id=2035

But it's not exactly what i want!I want to do it like engraved.So just leave your letters blank (or white) and the other places are black.Then try this etching method.So we can see that we have engraved looking panel.It's like making PCBs.

For me it's good idea!I will try this method with a peace of aluminum and i will share my exprience!

And it's an example of my front panel!

And there are lots of examples!

http://www.diystompboxes.com/smfforum/index.php?topic=85803.160

Another tutorial.

http://www.aronnelson.com/gallery/main.php/v/MarkMs-Gallery/album24/?g2_page=1

---------------------------------------

First of all,really expensive to make professional front panel for me.So i'm trying to find cheapest and easiest way to do it.

For now i used self adhesive paper for this.And some gear...

Looks good but not perfect!And little bit expensive,too!

I found another paste it to front panel with transparent glue.Then some coats of lacquer onto front panel.I belive it'll be better than self adhesive paper.I tried with some aluminum panel to see how it looks.And it's perfect!Really cheap,easy.I believe it's real DIY.

Do you have any idea to make custom front panels?Maybe cheaper or easier?

Thank.