mcfarlane_audio

Well-known member

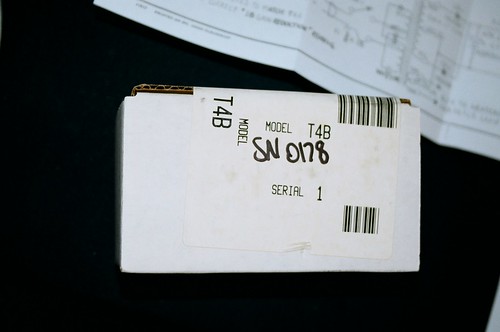

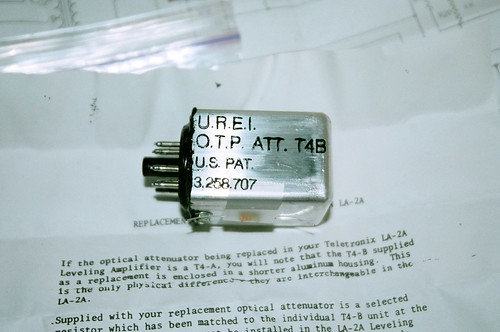

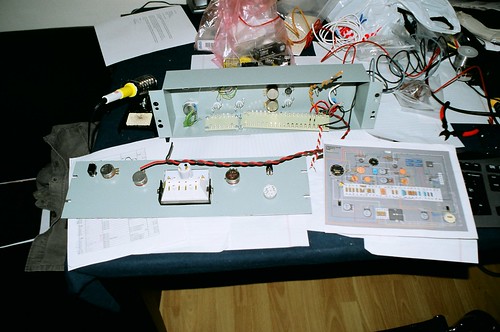

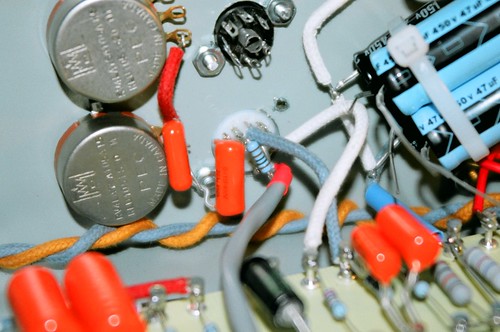

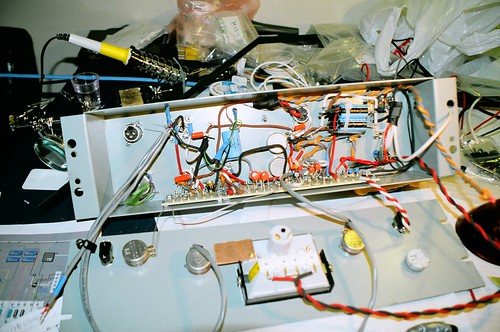

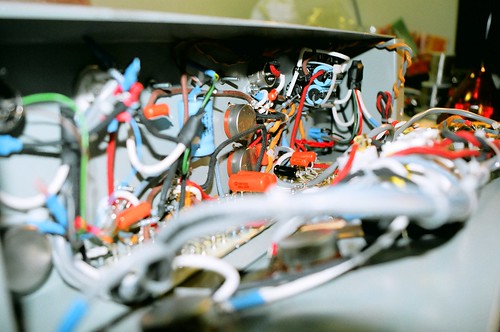

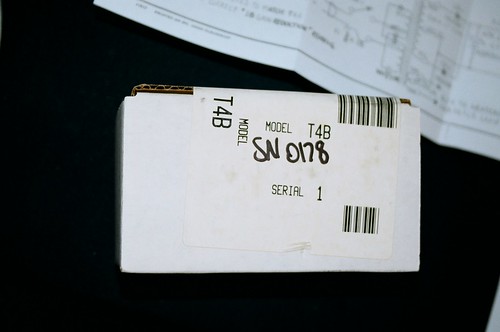

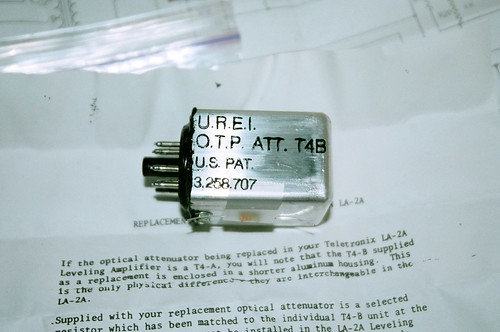

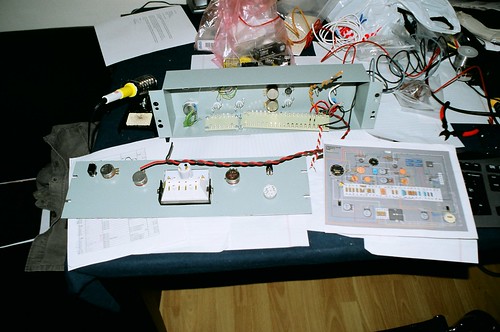

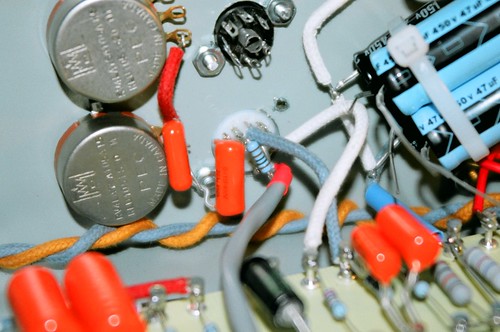

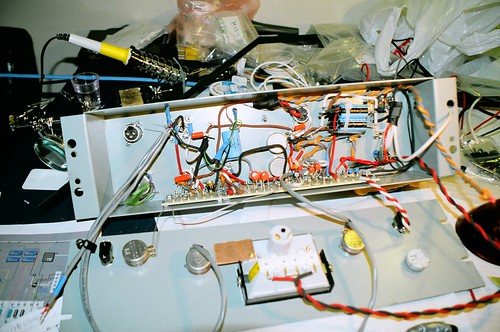

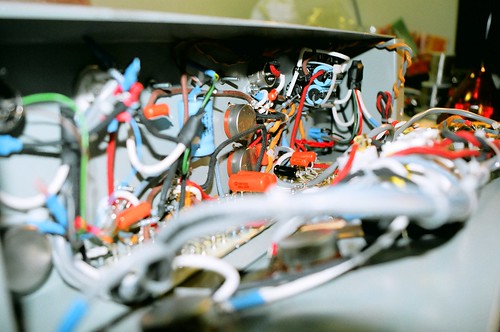

Hey well i thought it was about time to make a post, after lots of searching (and reading through hundreds of pages) i embarked upon my first real DIY project. The LA2A. well here are a few pictures documenting construction up to the finished unit. still needs a little cleaning up inside. but after solving some grond issues it sounds GREAT! :grin: ok well enough chat here are the pics ( really do hope they show up)

next ... gssl

next ... gssl