Dean Roddey

Well-known member

- Joined

- May 21, 2009

- Messages

- 81

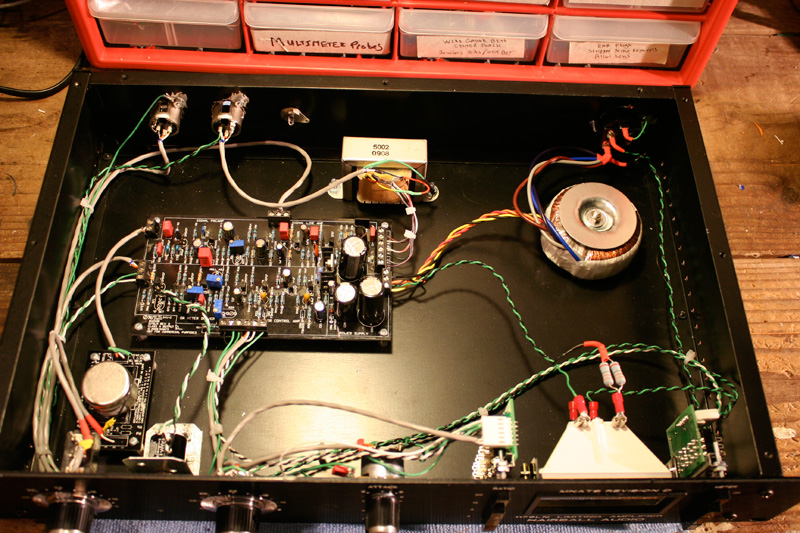

Oy vey... I wired the XLR sockets wrong, i.e. input for output. One of those forest for the trees things. So I'll have to swap those.

While I'm doing that, something I don't get. I was going to start tracing the signal in, to see where it was croaking. I set up a soft synth to generate a 1K sine and patched to my SSL comp and put the meter on in and adjusted the synth output to a steady 0dBVU there, so that I know it's good.

Before I discovered the above snafu, I started trying to measure the signal with my meter. Since I was not getting anything meaningful, I tried measuring them at the actual XLR cable pins on the male end. Shouldn't I be seeing about a 7 volt DC signal between two of the XLR pins? I'm not seeing anything at all.

Oh, and just in case... Do the settings of the other trim pots need to be set to any default setting before doing calibration step one? Or do they not even come into play becasue we've bypassed the GR circuit in this case?

While I'm doing that, something I don't get. I was going to start tracing the signal in, to see where it was croaking. I set up a soft synth to generate a 1K sine and patched to my SSL comp and put the meter on in and adjusted the synth output to a steady 0dBVU there, so that I know it's good.

Before I discovered the above snafu, I started trying to measure the signal with my meter. Since I was not getting anything meaningful, I tried measuring them at the actual XLR cable pins on the male end. Shouldn't I be seeing about a 7 volt DC signal between two of the XLR pins? I'm not seeing anything at all.

Oh, and just in case... Do the settings of the other trim pots need to be set to any default setting before doing calibration step one? Or do they not even come into play becasue we've bypassed the GR circuit in this case?