enthalpystudios

Well-known member

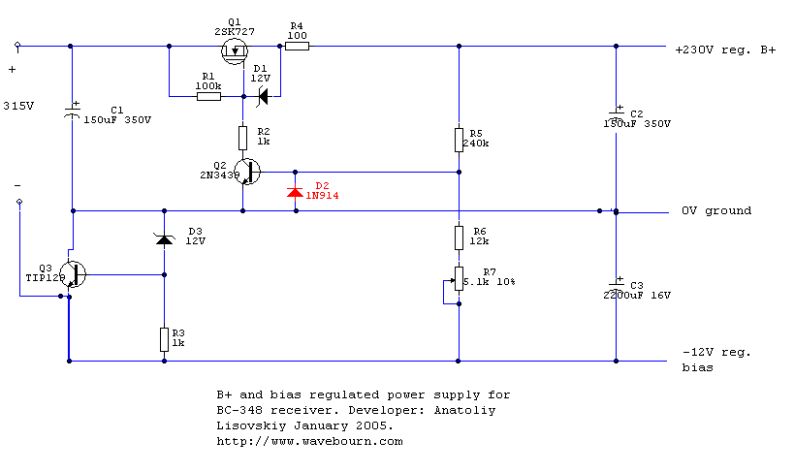

Anyone have a link I could start with for large supplies? I'd like to try for a power supply that I could use for many tube projects, 300vdc.

My first concern, however, could a low ripple psu like this be built without knowing the exact current draw? Also, could performance (ripple mostly) be affecting by drawing less current than the psu is designed for?

If not, than I'd like to shoot for an overbuilt psu with plenty of headroom, so that I could power different projects from the same unit. Otherwise, I'd better figure out exactly what I want to power so that I can have a specific load in mind.

Also, is this a poor idea from the standpoint of distribution, that is, will it be unsafe to carry high voltage dc across available connectors, perhaps xlr or some other common locking connector?

It just seems like a waste when you think about building projects that each have a their own power supply, especially when your plans often involve similar voltages. Would help noise as well.

I guess it's kind of the lunchbox strategy, but for tube gear.

My first concern, however, could a low ripple psu like this be built without knowing the exact current draw? Also, could performance (ripple mostly) be affecting by drawing less current than the psu is designed for?

If not, than I'd like to shoot for an overbuilt psu with plenty of headroom, so that I could power different projects from the same unit. Otherwise, I'd better figure out exactly what I want to power so that I can have a specific load in mind.

Also, is this a poor idea from the standpoint of distribution, that is, will it be unsafe to carry high voltage dc across available connectors, perhaps xlr or some other common locking connector?

It just seems like a waste when you think about building projects that each have a their own power supply, especially when your plans often involve similar voltages. Would help noise as well.

I guess it's kind of the lunchbox strategy, but for tube gear.