Consul

Well-known member

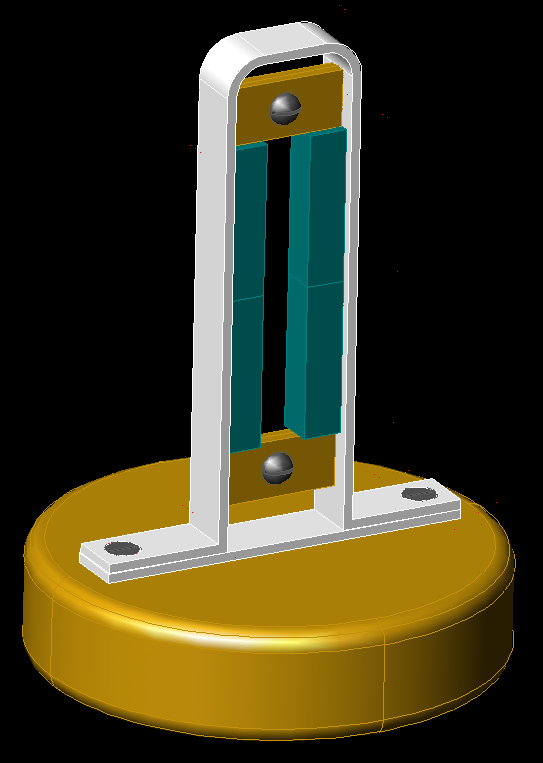

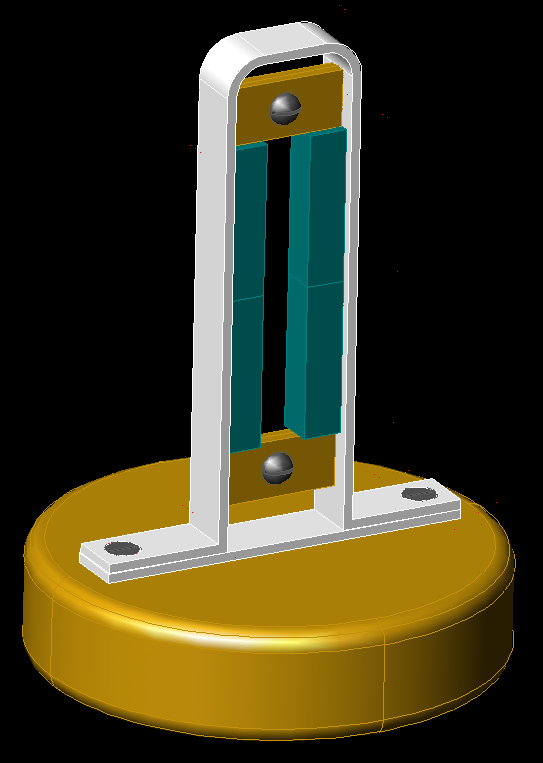

Well, that was the idea, anyway, when I drew this in engineering graphics class (aka CAD class):

The idea is to use modified angle brackets (that means bent at the top) plus a base bracket (at the bottom) to form a closed magnetic circuit. The ribbon clamps are an insulative material, which can be picked from many choices. One half of each clamp would be glued to the brackets, then the other would screw down, as can be seen in the drawing. The magnets are 1/4" x 1/4" x 1" neodymium jobbies that I already have in possession. As this is designed, it would accommodate a ribbon two inches long. The base is three inches in diameter to give a size reference.

Any thoughts? I just thought I'd run this by, and if it turns out to be a bad idea, I still get the class credit for it. :wink: Thanks!

The idea is to use modified angle brackets (that means bent at the top) plus a base bracket (at the bottom) to form a closed magnetic circuit. The ribbon clamps are an insulative material, which can be picked from many choices. One half of each clamp would be glued to the brackets, then the other would screw down, as can be seen in the drawing. The magnets are 1/4" x 1/4" x 1" neodymium jobbies that I already have in possession. As this is designed, it would accommodate a ribbon two inches long. The base is three inches in diameter to give a size reference.

Any thoughts? I just thought I'd run this by, and if it turns out to be a bad idea, I still get the class credit for it. :wink: Thanks!