crazydoc

Well-known member

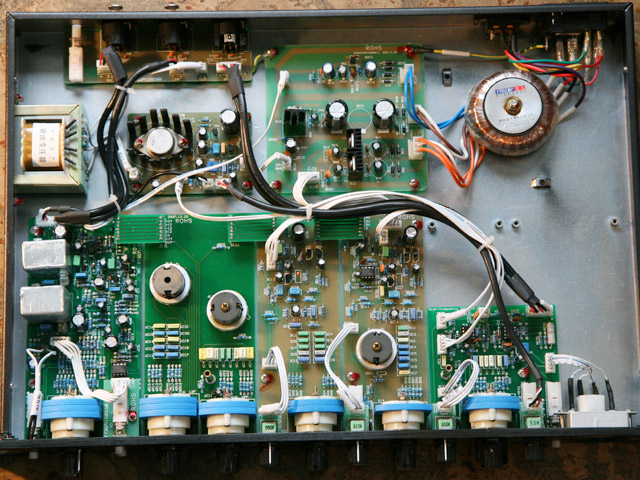

Another inductor hum hack I've done - raise the inductor up on stilts so it is centered in the shielding cylinder. (This is on the 73.) This is moderately helpful in further decreasing the level - the shield can only extend to the top of the 1U box, of course. Mounting it horizontally as I did in the ACMP81 is probably marginally more effective.

In any case, the hum on either unit is now only heard in the line-in position, with the output gain of the pre maxed and the input gain of the listening/recording device maxed. It is inaudible at any microphone setting, as the baseline noise of the preamp's gain stage is far greater than any inductor induced noise. I wish there were a way to decrease this: I've substituted several types of low noise transistors without any notable improvement.

To summarize, I've gotten my units functional by (in this order):

1) Swapping the Q4 and Q5 transistors to stop the oscillation (ACMP81)

2) Rotating the toroid power transformer to the position of least hum in the mid-eq inductors

3) Shielding the toroid and the inductors

4) Cutting the trace between the two poles of the 6th position of the input gain switch (not an optimal solution - loses a gain setting)

This has cost me about $30 per unit for 4 units ($12 for transistors and $100 for mumetal, though there is enough shielding left over to do a few more.) My only remaining issue is just the baseline preamp hash/noise at high mic gain, which shouldn't be a problem unless I'm recording a very soft voice/guitar with a ribbon mic. Thanks for everybody's help, energy and good will in working on this, with more to come as necessary.

Hopefully, Steve Hogan's entry into this will give some better options for those who want to pay a little more (and wait a little longer. )

)

In any case, the hum on either unit is now only heard in the line-in position, with the output gain of the pre maxed and the input gain of the listening/recording device maxed. It is inaudible at any microphone setting, as the baseline noise of the preamp's gain stage is far greater than any inductor induced noise. I wish there were a way to decrease this: I've substituted several types of low noise transistors without any notable improvement.

To summarize, I've gotten my units functional by (in this order):

1) Swapping the Q4 and Q5 transistors to stop the oscillation (ACMP81)

2) Rotating the toroid power transformer to the position of least hum in the mid-eq inductors

3) Shielding the toroid and the inductors

4) Cutting the trace between the two poles of the 6th position of the input gain switch (not an optimal solution - loses a gain setting)

This has cost me about $30 per unit for 4 units ($12 for transistors and $100 for mumetal, though there is enough shielding left over to do a few more.) My only remaining issue is just the baseline preamp hash/noise at high mic gain, which shouldn't be a problem unless I'm recording a very soft voice/guitar with a ribbon mic. Thanks for everybody's help, energy and good will in working on this, with more to come as necessary.

Hopefully, Steve Hogan's entry into this will give some better options for those who want to pay a little more (and wait a little longer.