Steve Hogan said:

It appears to me that the glue holding the pot core into the white shells is epoxy, so it will be a real pain to break them apart without damaging the pot core. To encase the whole thing with the white base requires a much larger (more expensive) can than would otherwise be necessary to just hold the inductor. I haven't removed the inductors and measured them as a standalone component yet. Maybe that is next.

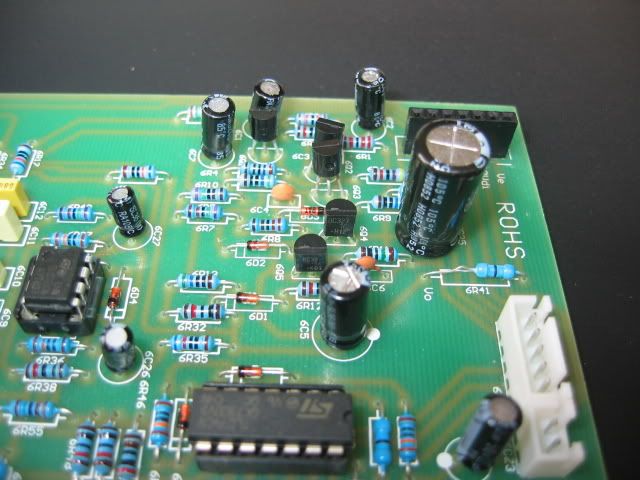

Today I removed samples of every inductor from an ACMP73, ACMP 84 and 2 ACMP-81 preamps. I also looked up the inductors made by Carnhill that most closely match the inductors in the TNC clones in order to figure out how difficult it would be to just make new, accurately made inductors in the smallest possible mu-metal cans to keep costs down.

I identified the exact core used by Carnhill to make their 9047 and 9048 inductors which look like a close match to the inductors in the '81. I need to get the DCR's of the Carnhill inductors in order to know how they differ from the clone inductors. Interestingly, these two Carnhill inductors are made from RM8 cores instead of Pot cores, so they have less self shielding than a similar pot core. They are assembled with grounded clips instead of Glue, which allows their somewhat conductive cores to act as an electrostatic shield.

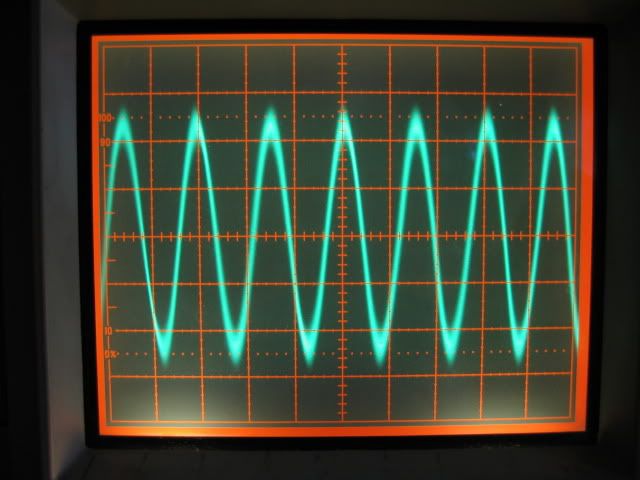

There were several interesting revelations as I measured, analyzed and compared 9 pcs of the factory supplied inductors. I measured DCR using my Fluke 8842A, and measured Inductance and Q using my GenRad 1659 Bridge.

Here are some observations:

1. All the Chinese inductors are made from the same size pot core. Maximum inductance is 6.3H and the lowest is 182 mH overall, leaving me to think that the gapping and/or the permeability/material of the cores may be different.

2. Interestingly, the 6L1 inductor and circuit values on the PCB in the 73 and 84 are identical. Both inductors measured very similarly, however,

The frequencies on the 73 panel say 300, 160, 80, 50, OFF

The frequencies on the 84 panel say 360, 160, 70, 45, OFF

I haven't measured yet the center frequencies of these EQ's yet, maybe neither one is correct.

3. The 5L1 inductor is identical in both the 73 and the 84. Both the circuit values and the PCB's are identical.

This time the kiloHertz frequencies also match: 7.2, 4.8, 3.2, 1.6, 0.7, 0.36, OFF

4. The 6L2 inductor in the '84 is unique to the '84 and does the high-cut filter. I measured only one piece.

5. The '81 4L1 and 5L1 inductors are unique to the '81. I measured 2 of each, and they were similar to each other.

6. The ferrites use for these types of inductors are actually fairly conductive. If you look at catalog photos of the Carnhill inductors, you will see that they have used standard metal clips to hold the two halves of the cores together. These spring clips are generally grounded. The cores on the Chinese inductors are not grounded, which may explain why the inductors are so prone to electrostatic pickup. Due to the difficulty of removing the pot cores from their white holder without cracking or otherwise breaking the pot cores, it is hard to add a grounding clip.

7. I won't bother to rehearse the numbers here, but I measured two of each type of inductor, with the exception of the high cut filter in the 73 6L2. There wasn't much variation between the samples, but they didn't quite read as advertised-- L5 in the 81's for example topped out at 4.7Hy when the schematic calls for 5Hy.

Thanks for emailing me with your power tranformer interest. I have almost all 40 pcs allocated.