lagoausente

Well-known member

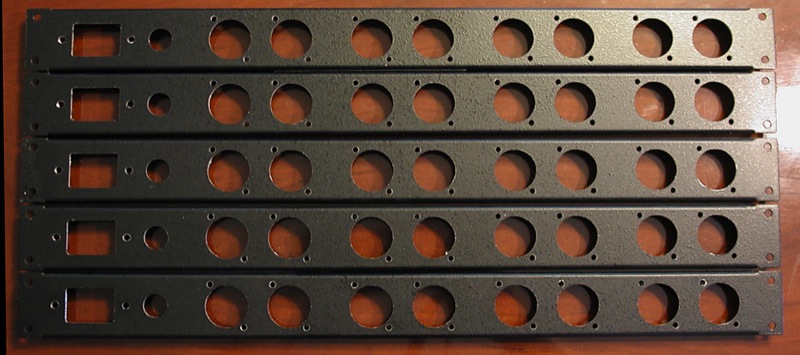

Hello, sometimme ago I have finished a Supergreen preamp, and built in in a case. I now want to change the case for a nice clear anodized one, and would like to get a good looking.

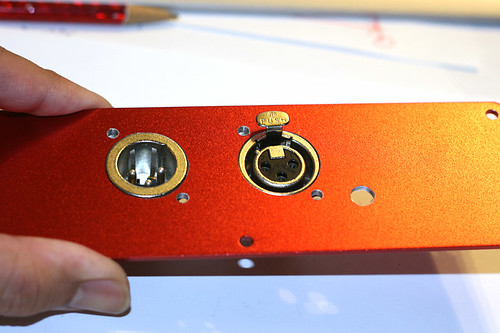

I´m planning to get a par-metal 20 series case, and would like to mount the knobs and jacks like in some comercial devices, I mean placing them behind the front panel, and so not using washers. Something like this: http://www.gracedesign.com/gallery/901.htm

I can make the knob holes with the 24mm punch, and the jack ones with a 12mm one, but the problem is to make 6mm ones for push buttons or switches because I don´t find punch of that diameter.

I have my doubts I could get a decent finish with a drill, so, anyone of you have experience with this? what´s the best option to get a round small 5 or 6mm hole? an special drill? any type of punch?

Any ideas would be apreciated.

Thanks for advanced.

I´m planning to get a par-metal 20 series case, and would like to mount the knobs and jacks like in some comercial devices, I mean placing them behind the front panel, and so not using washers. Something like this: http://www.gracedesign.com/gallery/901.htm

I can make the knob holes with the 24mm punch, and the jack ones with a 12mm one, but the problem is to make 6mm ones for push buttons or switches because I don´t find punch of that diameter.

I have my doubts I could get a decent finish with a drill, so, anyone of you have experience with this? what´s the best option to get a round small 5 or 6mm hole? an special drill? any type of punch?

Any ideas would be apreciated.

Thanks for advanced.