mulletchuck

Well-known member

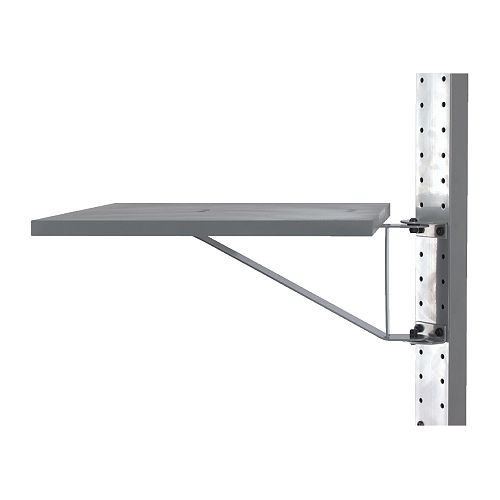

So, a few weeks ago, I rearranged my IKEA Jerker desk to allow me to work standing. And it is fantastic. but sometimes when i'm doing copywork in Finale, I don't want to work standing. So, this got me thinking that it would be kinda awesome to insert some car scissor lifts into the main support arms of the legs of this desk:

+

The idea is that the two lifts would be connected and i could use a power drill or some other electric motor to raise and lower the desk roughly 20 inches so I can work either sitting or standing. My desk only holds maybe 150 pounds (2 LCDs, 2 powered monitors, Kurzweil K2600xs, a bunch of External HDs, and an audio interface), so those scissor lifts are more than capable, weight-wise. However, i'd need to do some welding/metal-work to attach the scissor lifts to the desk legs. Could anyone shed some light on what else might be required, or perhaps a better solution? These scissor lifts are only like 20 bucks from Sears/Overstock.com so it's a very economical solution. I don't care at all about the visuals of it (it will be ugly hahaah).

+

The idea is that the two lifts would be connected and i could use a power drill or some other electric motor to raise and lower the desk roughly 20 inches so I can work either sitting or standing. My desk only holds maybe 150 pounds (2 LCDs, 2 powered monitors, Kurzweil K2600xs, a bunch of External HDs, and an audio interface), so those scissor lifts are more than capable, weight-wise. However, i'd need to do some welding/metal-work to attach the scissor lifts to the desk legs. Could anyone shed some light on what else might be required, or perhaps a better solution? These scissor lifts are only like 20 bucks from Sears/Overstock.com so it's a very economical solution. I don't care at all about the visuals of it (it will be ugly hahaah).