+1 8)It is important to reiterate that this posted test was performed on the OEM stock Alctron PCB's the specific properties of which we do not know, but likely they are "lowest cost possible". They are NOT the boards we are peddling in this thread. Matador's boards are manufactured with tightly controlled specification, materials, and processes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Official C12 Clone - Build and Support Thread

- Thread starter Matador

- Start date

Help Support GroupDIY Audio Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

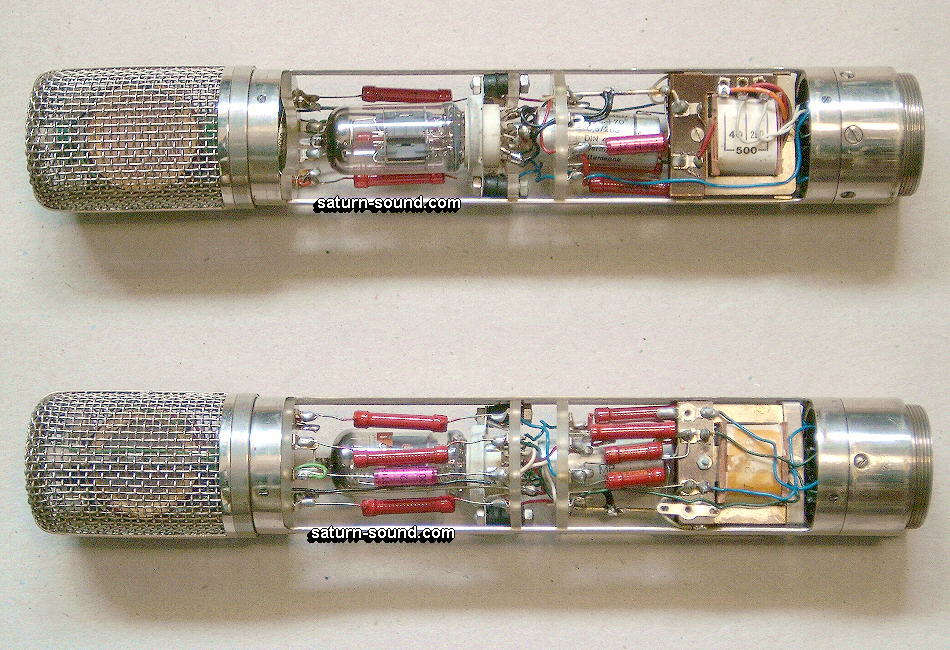

Hey Chunger,

I'm not trying to be controversial or undermine your self or Matador and I highly respect the work you guys have put into this build it's very admirable indeed! I was considering buying your boards as an alternative to modding the apex pcb by applying the C-12 circuit to it but I saw no need thinking the modded pcd should be the same . But then I ordered one of Tims capsules I thought if I'm going to spend $400 + on a capsule then I'm going all the way with the circuit board and building one from scratch which would give me the original point to point layout on acrylic! I didn't really expect to hear any difference but I knew I could sleep at night knowing that it was as close as I could possibly take it, so I was plesently surprised when it not only looked awesome but sounded way better! Also I don't think it has anything to do with the standoffs as the Apex board have them too.

. But then I ordered one of Tims capsules I thought if I'm going to spend $400 + on a capsule then I'm going all the way with the circuit board and building one from scratch which would give me the original point to point layout on acrylic! I didn't really expect to hear any difference but I knew I could sleep at night knowing that it was as close as I could possibly take it, so I was plesently surprised when it not only looked awesome but sounded way better! Also I don't think it has anything to do with the standoffs as the Apex board have them too.

Again I'm not implying that your board has the same issue! test so far have only been with modded Apex boards... Have you tested your boards up against an Apex modded with identical circuit and components?

I'm not trying to be controversial or undermine your self or Matador and I highly respect the work you guys have put into this build it's very admirable indeed! I was considering buying your boards as an alternative to modding the apex pcb by applying the C-12 circuit to it but I saw no need thinking the modded pcd should be the same

Again I'm not implying that your board has the same issue! test so far have only been with modded Apex boards... Have you tested your boards up against an Apex modded with identical circuit and components?

I'd be happy for us to send a set of boards to each other to run our own tests if your interested? It's really the only definitive way to know where the differences if any lie.I do encourage someone to make that head-to-head test.

Matador

Well-known member

The only way to be completely fair would be to build up a mike with a given set of components, do a slew of measurements, then completely rebuild the mike again with the exact same components and hope nothing changed in the process.  And it has to be double blind...and probably repeated a few times...otherwise the experiment becomes simply to show that different mikes sound different. Microphones are doubly-difficult to do this test because even 1 inch difference in positioning in a room can yield many dB of frequency response differences.

And it has to be double blind...and probably repeated a few times...otherwise the experiment becomes simply to show that different mikes sound different. Microphones are doubly-difficult to do this test because even 1 inch difference in positioning in a room can yield many dB of frequency response differences.

First off, the Apex 460 is a completely different circuit: it's a cathode follower / CCDA circuitry, different ratio transformer, cathode bias (with different values for the bypass cap), plate coupling cap is a different value (and is electrolytic!), the polarization string is different, the plate resistor as an extra plate cap, the transformer secondary has *very* large RF suppressors, the PSU is Zener regulated, the backplate polarizer has a HUGH bypass cap (they call it C2) missing from the C12 ... the list goes on and on.

What exact mods did you do on your Apex? Did you pull all of those exact same components out to build the P-2-P version or did you build a new mike with different components?

The devil is always in the details.

First off, the Apex 460 is a completely different circuit: it's a cathode follower / CCDA circuitry, different ratio transformer, cathode bias (with different values for the bypass cap), plate coupling cap is a different value (and is electrolytic!), the polarization string is different, the plate resistor as an extra plate cap, the transformer secondary has *very* large RF suppressors, the PSU is Zener regulated, the backplate polarizer has a HUGH bypass cap (they call it C2) missing from the C12 ... the list goes on and on.

What exact mods did you do on your Apex? Did you pull all of those exact same components out to build the P-2-P version or did you build a new mike with different components?

The devil is always in the details.

I hate to interrupt this 'comparison' discussion  but I thought I'd better put this here for all to see:

but I thought I'd better put this here for all to see:

Hi Matador,

I’ve really appreciated your recent posts regarding the more in depth theory as to what is happening with the electrons within the circuit.

Specifically the mention of the hi z section of the c12 project.

I’ve been experiencing some hissing/buzzing down in the noise floor and am not sure but suspect it to be related to the hi z section and my admittedly poor cleaning of heavy rosin flux. I’m not getting any significant low end roll off, perhaps this suggests my problem lies elsewhere? In fact I was surprised at how beefy it sounds, even with the hissy/buzzy noise floor. Not a ground hum but buzzy fizzy, ha love the audio adjectives.

Transformer is AMI, capsule is Beesneez k12, tube is 6072a from Christian Whitmore (BOWIE)

My question, what symptoms would one expect should these sections have high resistance paths to ground or leakage current. I read what you said about the filter frequency being influenced, would added noise be a result as well?

I used 91% ISA and can unfortunately still see a film of residue.

My initial thought is to lift connections between both backplates and Teflon pins at the pcb. Lift the capsule side legs of c13 and r14. Jumper my backplates and pry to the microphone gods… but first I thought it best to consult with you.

Thank you for your time and for the project!

Best Regards

Hi Matador,

I’ve really appreciated your recent posts regarding the more in depth theory as to what is happening with the electrons within the circuit.

Specifically the mention of the hi z section of the c12 project.

I’ve been experiencing some hissing/buzzing down in the noise floor and am not sure but suspect it to be related to the hi z section and my admittedly poor cleaning of heavy rosin flux. I’m not getting any significant low end roll off, perhaps this suggests my problem lies elsewhere? In fact I was surprised at how beefy it sounds, even with the hissy/buzzy noise floor. Not a ground hum but buzzy fizzy, ha love the audio adjectives.

Transformer is AMI, capsule is Beesneez k12, tube is 6072a from Christian Whitmore (BOWIE)

My question, what symptoms would one expect should these sections have high resistance paths to ground or leakage current. I read what you said about the filter frequency being influenced, would added noise be a result as well?

I used 91% ISA and can unfortunately still see a film of residue.

My initial thought is to lift connections between both backplates and Teflon pins at the pcb. Lift the capsule side legs of c13 and r14. Jumper my backplates and pry to the microphone gods… but first I thought it best to consult with you.

Thank you for your time and for the project!

Best Regards

Matador

Well-known member

As another aside: this debate has raged on for years in the guitar amp world. Google "fender pcb amp versus point to point" and the internet will explode.

I was asked what flux residue sounds like, if not causing a noticeable frequency shift. My analogy before was flawed on purpose for simplicity - I said it's "no different" from soldering a 60M resistor. In reality, it's quite different. The impedance here isn't exactly well known, and is highly voltage dependent. What this means is that this phantom resistor can appear and disappear at random, causing all number of weird noises.

One is a sizzling, crackling noise - this is as this resistor pops into being, changes the charge on the capsule, then disappears rapidly. Tubes can also cause this noise so it's hard to diagnose. Sometimes, the noise floor appears to rise.

The best way to clean is right after the resistors and tube board + socket are soldered in, but before any styrene caps are installed. Fill up a cup with about 1 inch of IPA and dunk the whole board in. Scrub with a toothbrush as Chunger showed, then dunk again. Keep doing this until the PCB looks shiny and clear, and you can run you finger across the surface without it feeling "sticky". PCB houses use ultrasonic cleaners with various solvents to do the job.

If this still doesn't work, you can use a high-strength solvent, but you have to be more careful where it goes. Most of the components used in this design are epoxy coated and will not be harmed with stronger solvents (like mineral spirits and acetone) but I would stick with IPA...it will just take longer.

I was asked what flux residue sounds like, if not causing a noticeable frequency shift. My analogy before was flawed on purpose for simplicity - I said it's "no different" from soldering a 60M resistor. In reality, it's quite different. The impedance here isn't exactly well known, and is highly voltage dependent. What this means is that this phantom resistor can appear and disappear at random, causing all number of weird noises.

One is a sizzling, crackling noise - this is as this resistor pops into being, changes the charge on the capsule, then disappears rapidly. Tubes can also cause this noise so it's hard to diagnose. Sometimes, the noise floor appears to rise.

The best way to clean is right after the resistors and tube board + socket are soldered in, but before any styrene caps are installed. Fill up a cup with about 1 inch of IPA and dunk the whole board in. Scrub with a toothbrush as Chunger showed, then dunk again. Keep doing this until the PCB looks shiny and clear, and you can run you finger across the surface without it feeling "sticky". PCB houses use ultrasonic cleaners with various solvents to do the job.

If this still doesn't work, you can use a high-strength solvent, but you have to be more careful where it goes. Most of the components used in this design are epoxy coated and will not be harmed with stronger solvents (like mineral spirits and acetone) but I would stick with IPA...it will just take longer.

.The only way to be completely fair would be to build up a mike with a given set of components, do a slew of measurements, then completely rebuild the mike again with the exact same components and hope nothing changed in the process.And it has to be double blind...and probably repeated a few times...otherwise the experiment becomes simply to show that different mikes sound different. Microphones are doubly-difficult to do this test because even 1 inch difference in positioning in a room can yield many dB of frequency response differences

I'm not thinking of anything quite that complex if we cant hear a substantial difference with our ears then the debate would be over. The mics would obviously have the same brand/value components, each of us could test the mics and then test again but swap capsule, tube input and output caps and transformer to eliminate differences in those parts or swap all of the components if you feel that's necessary.

I thought I had made this clear alreadyFirst off, the Apex 460 is a completely different circuit: it's a cathode follower / CCDA circuitry, different ratio transformer, cathode bias (with different values for the bypass cap), plate coupling cap is a different value (and is electrolytic!), the polarization string is different, the plate resistor as an extra plate cap, the transformer secondary has *very* large RF suppressors, the PSU is Zener regulated, the backplate polarizer has a HUGH bypass cap (they call it C2) missing from the C12 ... the list goes on and on.

What exact mods did you do on your Apex? Did you pull all of those exact same components out to build the P-2-P version or did you build a new mike with different components?

The devil is always in the details.

Yes the devil is in the details

Again I will repeat the fact that AKG and Neuman both used acrylic mounted components in the high impedance sections of the C-12 Ela 251M and U47, They actively did this for a reason as there were other circuit board materials around. Point to point was a given, a standard for the time but to specifically select acrylic for the Hi Z section in the U-47 or the whole mic in the case of the C12 and 251, I think there just might be more to it then the old tired point to point argument

Acrylic was also used in the Ck12 capsule as an insulator

I would still love to run the tests between the two methods as it would be a great learning opportunity as this would be a very telling test and pretty clear cut if we both do it and present it here.

Matador

Well-known member

OPR said:They actively did this for a reason as there were other circuit board materials around.

Do you have a primary source for this? What materials did they have to choose from? What were their properties? Could they be manufactured in-mass? What decisions were made, experiments run, that ultimately led to the final design choices?

Impedance controlled / polymerized PCB coatings were invented at least 35 years after these mikes were produced. I'm not sure exactly what the point is here: they used what was available at the time. Even crude hand-drawn PCB's didn't arrive in "mass production" until the mid 60's. I think even the lowly FR-4 material wasn't being used for mass-produced PCB's until the late 60's.

PET/Acrylic resin(s) was/were probably a good choice at the time: it was inexpensive, easy to machine/cast, could be repeatably assembled, and most important of all, caused very low yield loss (e.g. $$) when built in the many thousands.

So back to your point: I remember your test, and I remember they sounded different. They still sound different to me. Was the same capsule, same tube, and same components used? Not the same type, or same value, or even same brand... the exact same physical components used? Caps have high tolerance, as do transformers and capsules...to that point even two otherwise identical C12's/U47's/ELA M251's will sound different from each other.

Do you have a primary source for this? What materials did they have to choose from? What were their properties? Could they be manufactured in-mass? What decisions were made, experiments run, that ultimately led to the final design choices?

I'm not going to pretend that I know why they made the choices they did be they sonic economic or otherwise but I feel that these decisions have left a sonic footprint on these mics for the better or worse.

Impedance controlled / polymerized PCB coatings were invented at least 35 years after these mikes were produced. I'm not sure exactly what the point is here: they used what was available at the time. Even crude hand-drawn PCB's didn't arrive in "mass production" until the mid 60's. I think even the lowly FR-4 material wasn't being used for mass-produced PCB's until the late 60's.

Yes they did use what was available at the time..I'm not arguing better or worse just that they would most likely sound different for better or worse.

PET/Acrylic resin(s) was/were probably a good choice at the time: it was inexpensive, easy to machine/cast, could be repeatably assembled, and most important of all, caused very low yield loss (e.g. $$) when built in the many thousands.

Again the U47 only used acrylic in the Hi Z section the other parts look to be be the standard board material. why didn't they feel the board material was up to scratch for the Hi Z? there must be some sort of sonic impact..and even with today's Impedance controlled / polymerized PCB coatings it would be interesting to know how they compare and what sort of impact the different substrates have on the sound.

So back to your point: I remember your test, and I remember they sounded different. They still sound different to me. Was the same capsule, same tube, and same components used.Not the same type, or same value, or even same brand... the exact same physical components used? Caps have high tolerance, as do transformers and capsules...to that point even two otherwise identical C12's/U47's/ELA M251's will sound different from each other.

Not the same physical components but same value/brand...I did swap capsule and tube between the mics with the same results. I've also built quite a few mics p to p and pcb hacked with the same results over and over.

Bar the Chinese capsule, I doubt the difference would be this big between the components otherwise no body on the planet could make a consistent mic

Anyhow the only way to know is to test and listen ;D

Matador

Well-known member

Edit: nevermind...there's no way to advance this debate in a substantive manner.

The only way would be to do the tests and listen to the results.there's no way to advance this debate in a substantive manner.

I really hope I haven't offended or upset yourself or Chunger as I really do appreciate and respect you both and the work you do!

peace!

chunger

Well-known member

Someone somewhere will test this. . .there are plenty of these builds in circulation now in all parts of the world. For now, my development and testing efforts are focused on getting the ELA build documented as well as comparatively testing the various tube options that are now prototyped and functioning in the circuit. . . so that we can make a decisive recommendation for full kits (for budget variant). Development resources are also allocated to building a set of test mics for capsule evaluation. . . specifically finding a good tuning for tskguy's upcoming capsules and testing a variety of Chinese capsule options from various factories.

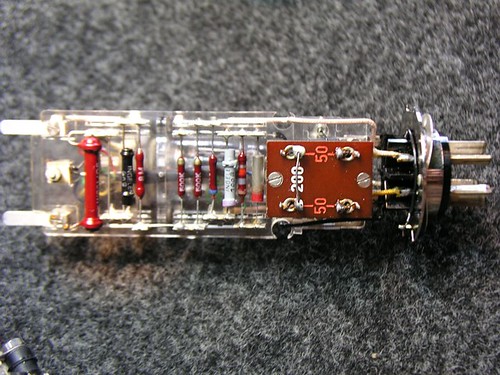

Eventually, I will build a teflon extravaganza of an isolated point to point variant to test based on the proto board that is currently available, but operationally as far as this enterprise is concerned, I defer to Matador's expertise on technical matters of layout, materials, development priorities, and BOM. This is, after all, a build and support thread for his design!

Other threads including OPR's own support thread for his commercial venture can further debate the issue and run tests as he designs and sees fit. There are a myriad of reasons we structured our kit the way we did, and those choices were not made blindly. Cost, repeatability, longevity, flexibility, intuitive build process, ease of post-build diagnostics, and integrity of the circuit implementation all figured in and when executed correctly with good components, the resulting build is by any standard a great mic.

OPR has a pretty retail point to point mic at a great price-point and provides parts for the build if people are so inclined. I've referred people to buy his mic who I felt were not quite ready to jump into a DIY project of this type and desire a point to point C12 clone built with care. At just ~$500 above an all-out premium build on our kit, I felt it to be a superbly reasonable recommendation (Assuming that model carries Tim Campbell's capsule or equivalent reproduction chambered capsule).

That being said, there are no magic bullet materials (even old ones). . . prominent restoration shops have reported acrylic ELA M251's have been known to develop strange issues as the material ages and all manner of problems that were only resolved by re-manufacturing the entire base structure. Know what you're using and why. I do not think Tim Campbell is using Acrylic in his reproduction capsules. . . likely it is because a better material is being used as he is not one to compromise and holds to vintage specs more closely than anyone else in the business.

If Matador does not find it constructive to go back and forth on this thread further concerning PTP vs. PCB (much information has already been presented along with beautiful sound clips of "not this kit"), I think it probably good to start another thread elsewhere or pick up the subject on OPR's support thread because quite honestly, we need Matador here to help answer technical questions as they relate to this kit!

Eventually, I will build a teflon extravaganza of an isolated point to point variant to test based on the proto board that is currently available, but operationally as far as this enterprise is concerned, I defer to Matador's expertise on technical matters of layout, materials, development priorities, and BOM. This is, after all, a build and support thread for his design!

Other threads including OPR's own support thread for his commercial venture can further debate the issue and run tests as he designs and sees fit. There are a myriad of reasons we structured our kit the way we did, and those choices were not made blindly. Cost, repeatability, longevity, flexibility, intuitive build process, ease of post-build diagnostics, and integrity of the circuit implementation all figured in and when executed correctly with good components, the resulting build is by any standard a great mic.

OPR has a pretty retail point to point mic at a great price-point and provides parts for the build if people are so inclined. I've referred people to buy his mic who I felt were not quite ready to jump into a DIY project of this type and desire a point to point C12 clone built with care. At just ~$500 above an all-out premium build on our kit, I felt it to be a superbly reasonable recommendation (Assuming that model carries Tim Campbell's capsule or equivalent reproduction chambered capsule).

That being said, there are no magic bullet materials (even old ones). . . prominent restoration shops have reported acrylic ELA M251's have been known to develop strange issues as the material ages and all manner of problems that were only resolved by re-manufacturing the entire base structure. Know what you're using and why. I do not think Tim Campbell is using Acrylic in his reproduction capsules. . . likely it is because a better material is being used as he is not one to compromise and holds to vintage specs more closely than anyone else in the business.

If Matador does not find it constructive to go back and forth on this thread further concerning PTP vs. PCB (much information has already been presented along with beautiful sound clips of "not this kit"), I think it probably good to start another thread elsewhere or pick up the subject on OPR's support thread because quite honestly, we need Matador here to help answer technical questions as they relate to this kit!

Thanks for the Kind words Chunger!  I really love you work too! Those head baskets are glorious! and I cant wait to see your u47 bodies!! are they far off?

I really love you work too! Those head baskets are glorious! and I cant wait to see your u47 bodies!! are they far off?

Just to be clear I use Uv stabilized Acrylic in my boards which is made to take a beating in outdoor applications and in direct sunlight doesn't degrade like the the old material... Also I wasn't aware that Tim wasn't using acrylic in his capsules, can you post a link where he discusses this? Not that it matters too much as I'm sure he is using something with similar electrical properties.

prominent restoration shops have reported acrylic ELA M251's have been known to develop strange issues as the material ages and all manner of problems that were only resolved by re-manufacturing the entire base structure. Know what you're using and why. I do not think Tim Campbell is using Acrylic in his reproduction capsules. . . likely it is because a better material is being used as he is not one to compromise and holds to vintage specs more closely than anyone else in the business.

Just to be clear I use Uv stabilized Acrylic in my boards which is made to take a beating in outdoor applications and in direct sunlight doesn't degrade like the the old material... Also I wasn't aware that Tim wasn't using acrylic in his capsules, can you post a link where he discusses this? Not that it matters too much as I'm sure he is using something with similar electrical properties.

Matador

Well-known member

OPR said:I really hope I haven't offended or upset yourself or Chunger as I really do appreciate and respect you both and the work you do!

peace!

No worries! I'm fine to continue the discussion, just not here.

Matador

Well-known member

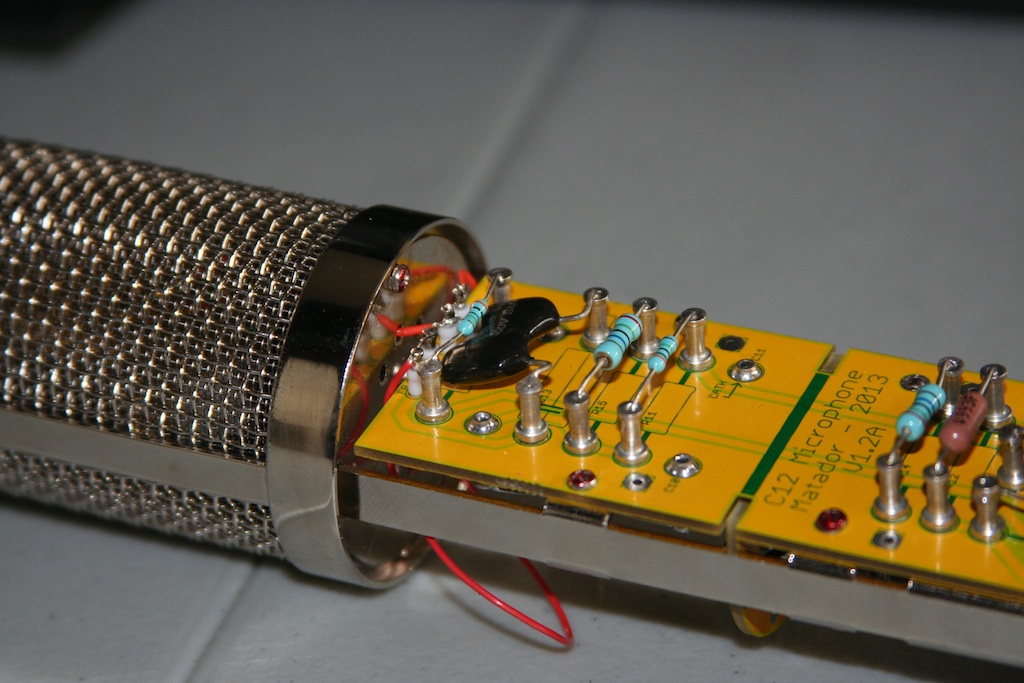

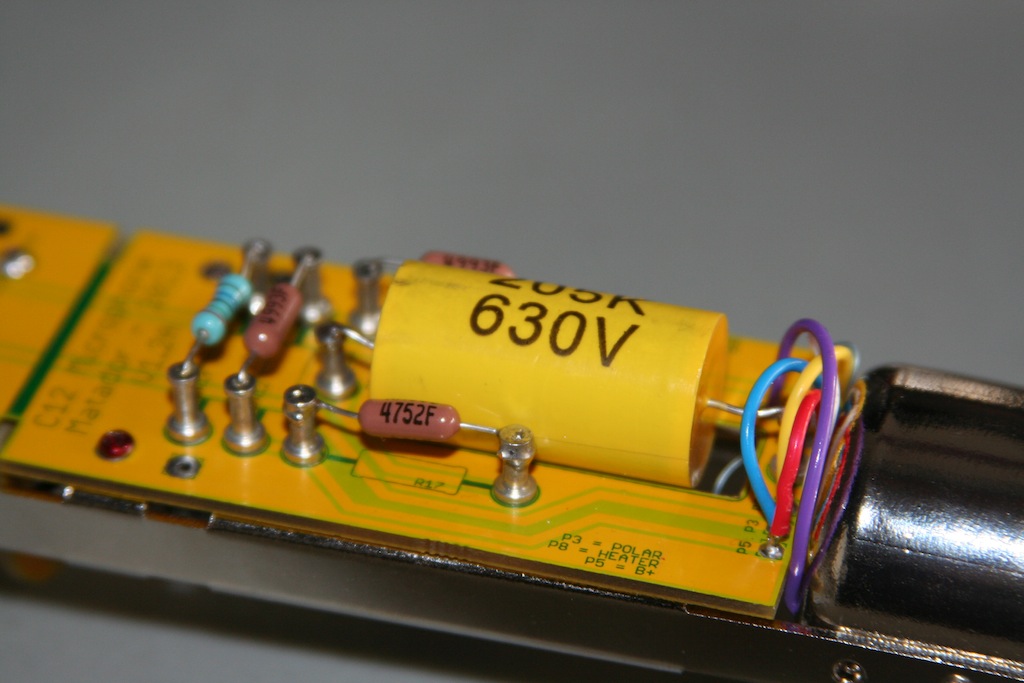

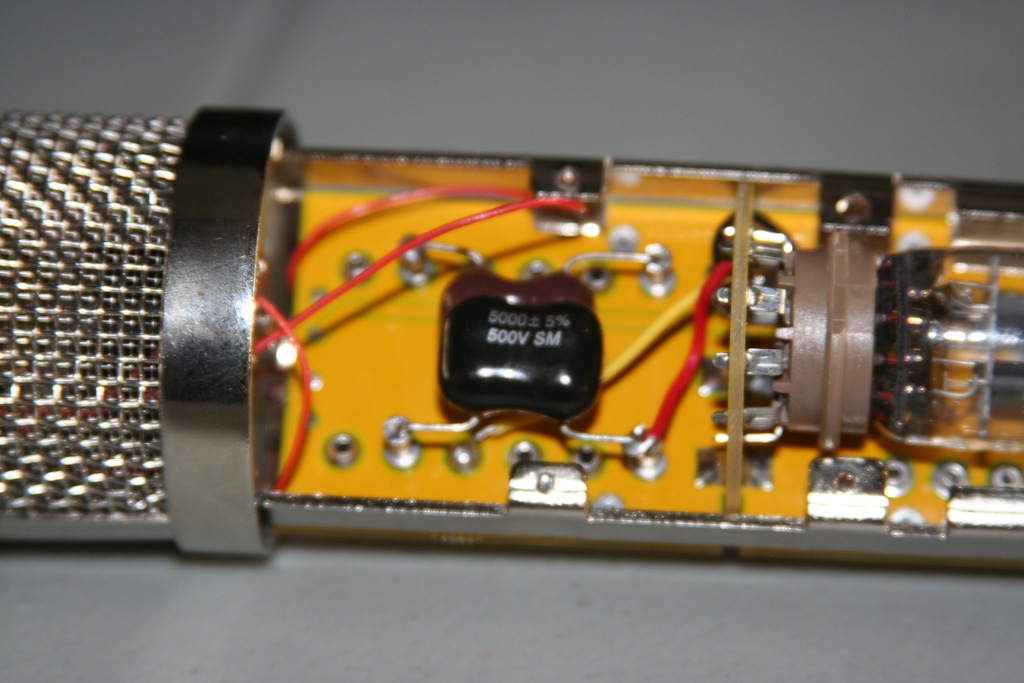

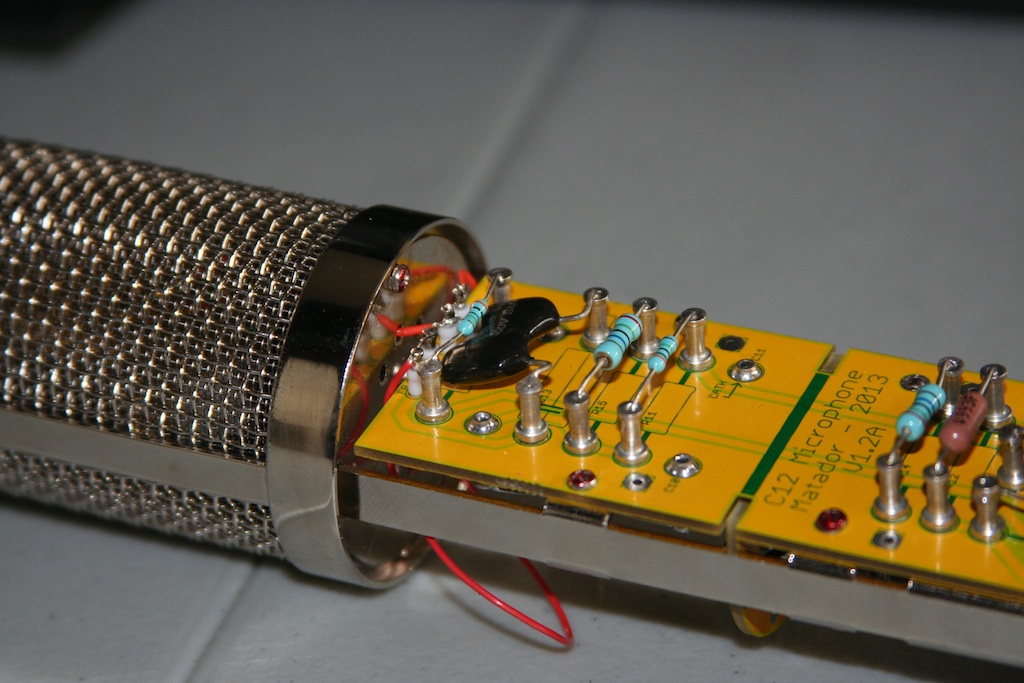

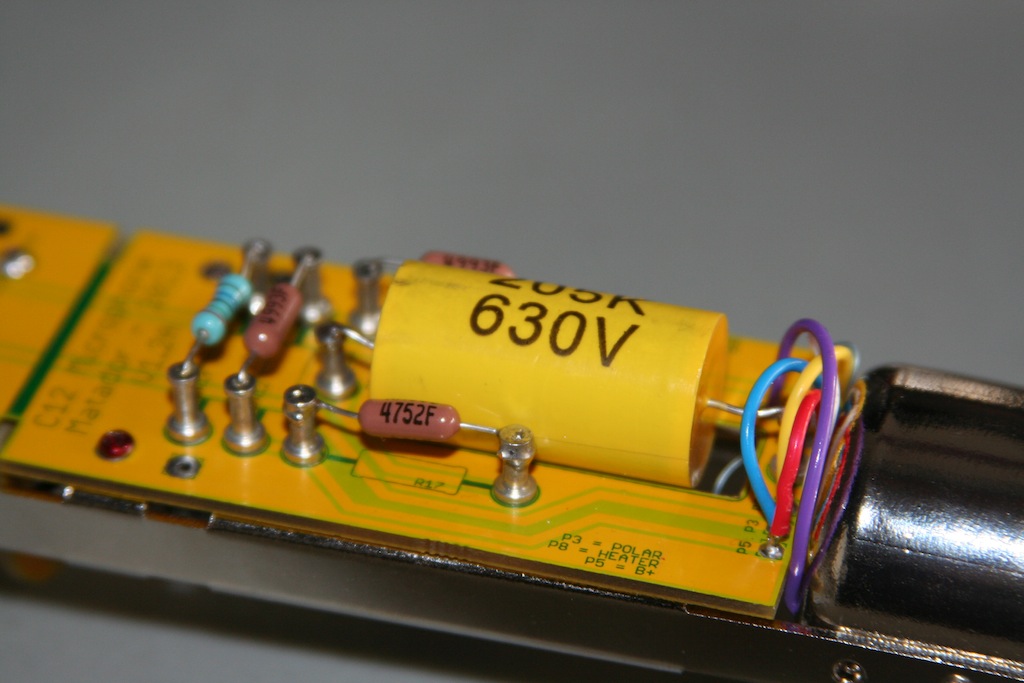

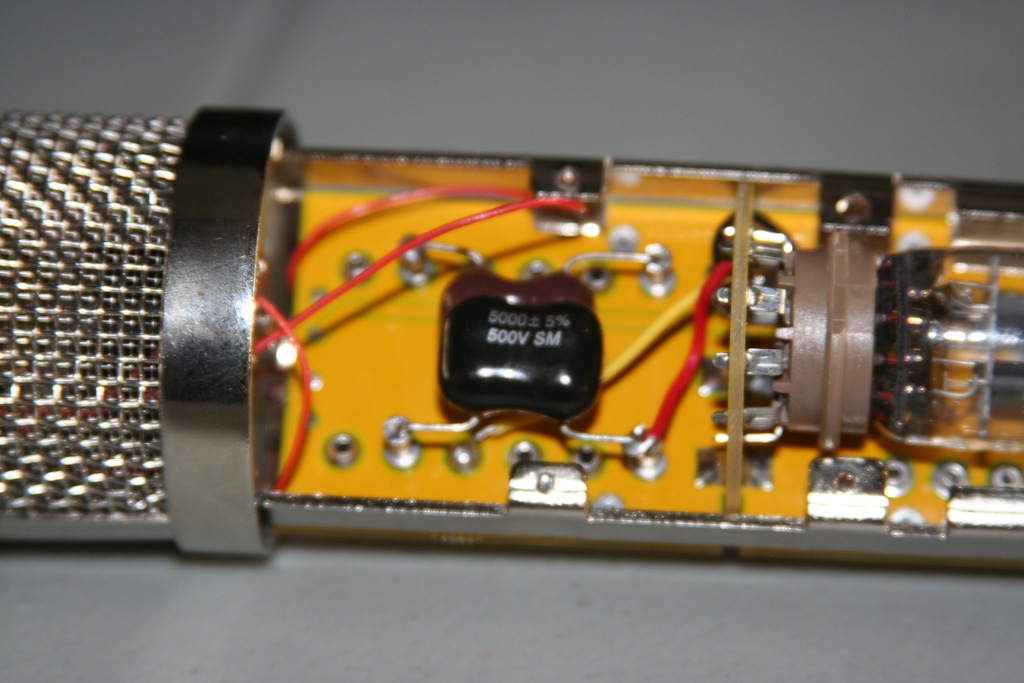

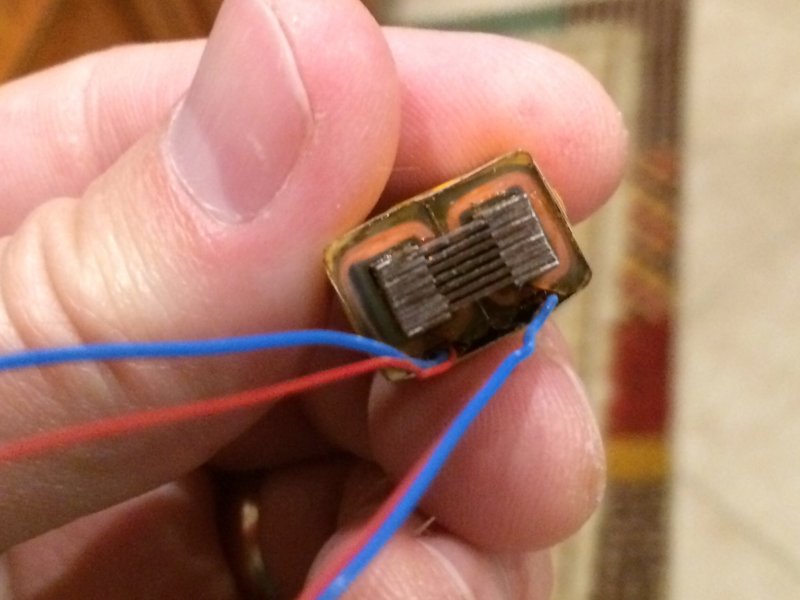

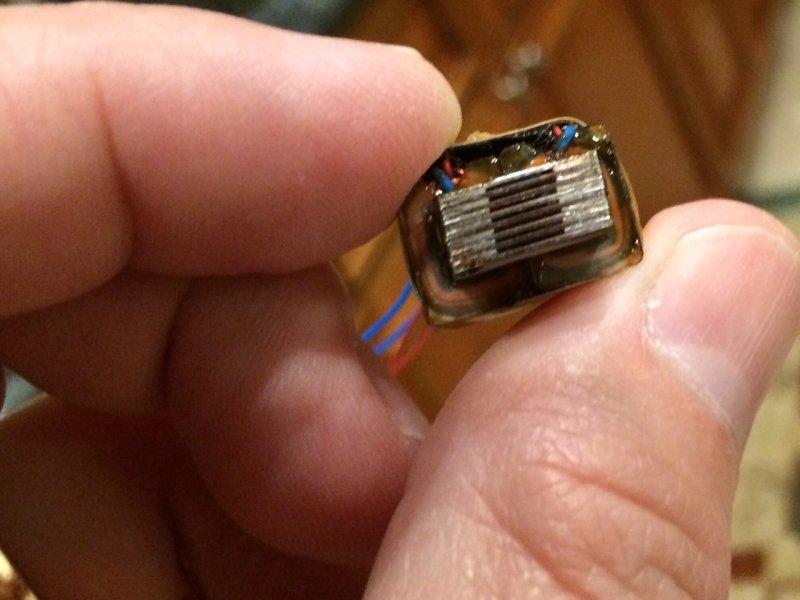

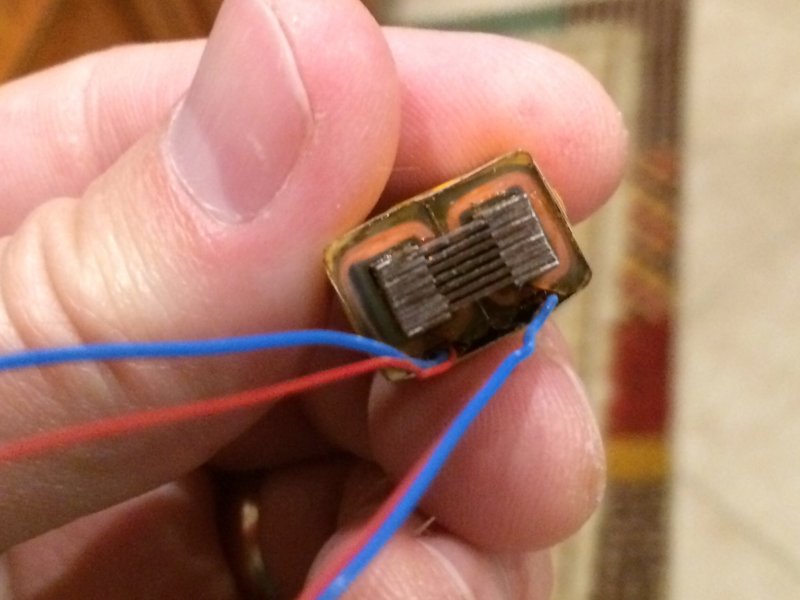

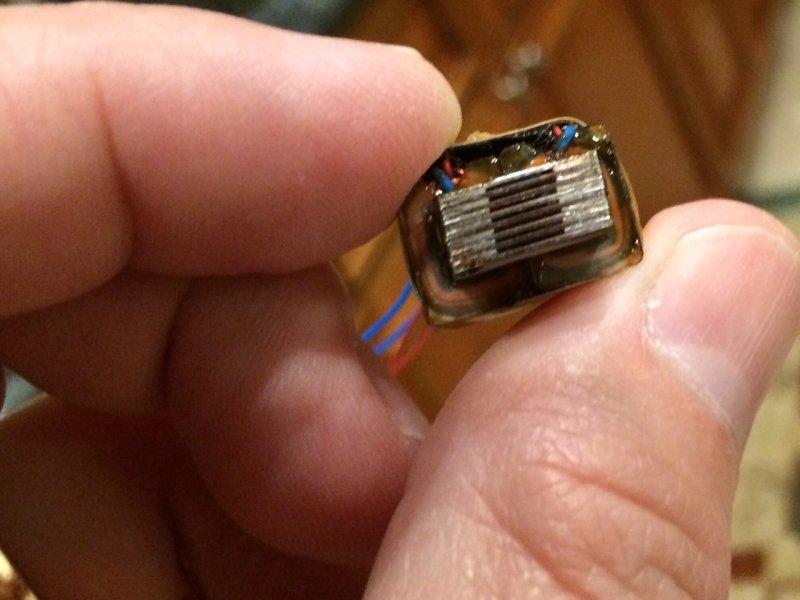

Speaking of building mikes: shots of the mica caps and 12AT7 conversion. It's very simple actually:

C13 becomes silver mica:

A huge 2uF cap for C12, and R17 (plate resistor) goes down to 47K:

Small filter caps (C10 and C11) go under the board as before, silver mica's as well:

And of course, the tube swap:

All fired up and sounded fine with my test capsule. Now I need a real capsule to test with before I turn it over to the studio for more abuse!

The mica caps are from JustRadios.com, and I think go for about $4 a piece in small quantities.

C13 becomes silver mica:

A huge 2uF cap for C12, and R17 (plate resistor) goes down to 47K:

Small filter caps (C10 and C11) go under the board as before, silver mica's as well:

And of course, the tube swap:

All fired up and sounded fine with my test capsule. Now I need a real capsule to test with before I turn it over to the studio for more abuse!

The mica caps are from JustRadios.com, and I think go for about $4 a piece in small quantities.

micaddict

Well-known member

Matador, you da man.

me too!No worries! I'm fine to continue the discussion, just not here.This thread is about building C12's!

scott_humphrey

Well-known member

MicDaddy said:I’ve been experiencing some hissing/buzzing down in the noise floor and am not sure but suspect it to be related to the hi z section and my admittedly poor cleaning of heavy rosin flux. I’m not getting any significant low end roll off, perhaps this suggests my problem lies elsewhere? In fact I was surprised at how beefy it sounds, even with the hissy/buzzy noise floor. Not a ground hum but buzzy fizzy, ha love the audio adjectives.

Transformer is AMI, capsule is Beesneez k12, tube is 6072a from Christian Whitmore (BOWIE)

My question, what symptoms would one expect should these sections have high resistance paths to ground or leakage current. I read what you said about the filter frequency being influenced, would added noise be a result as well?

I used 91% ISA and can unfortunately still see a film of residue.

My initial thought is to lift connections between both backplates and Teflon pins at the pcb. Lift the capsule side legs of c13 and r14. Jumper my backplates and pry to the microphone gods… but first I thought it best to consult with you.

Thank you for your time and for the project!

Best Regards

Before doing this I'd suggest trying another tube. A bad tube is the usual suspect for the symptoms that you are describing. Second most likely is a bad solder joint.

I've modded my board to use teflon standoffs for the high impedence sections. I wasn't very scientific in comparing before and after results, but to my ears the post-mod mic seems to have a slightly increased bass response. I'm not advocating that everyone do this mod. This mic sounds great either way. I just did it because, in theory, it made sense to me. The mod had no effect on the mic's self noise level.

Category 5

Well-known member

Anyone know if this could be an issue? I think not, but why not ask.

Category 5

Well-known member

OPR said:I had a few all crooked like that also, l asked Oliver about them and told me it would have no impact on the sound.

Thanks OPR. After the super neat installation I did inside the bell housing that's what I wanted to hear. I hate disassembling my builds. ;-)

Similar threads

- Replies

- 274

- Views

- 15K

- Replies

- 14

- Views

- 1K