Maybe it is so obvious, that i shouldn't share with that, but for me for yesterday wasn't, so maybe it will be useful solution for someone else

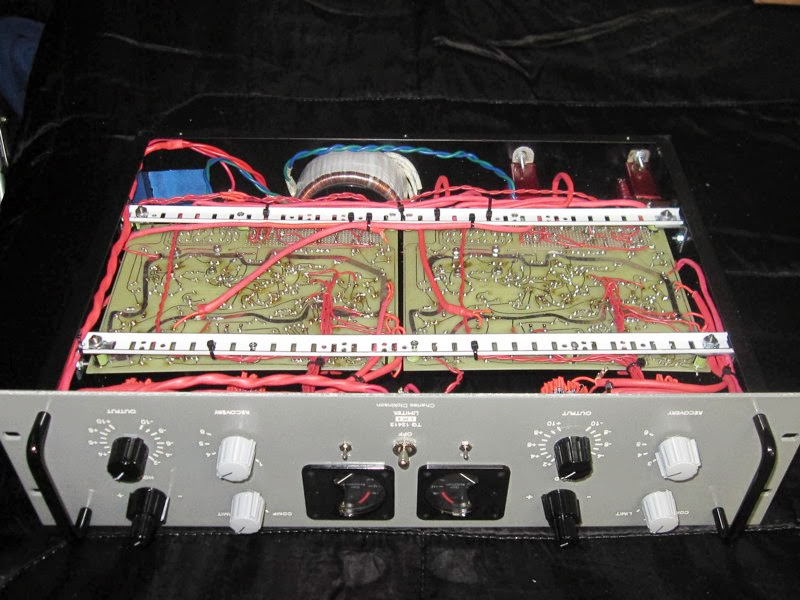

I always drill housings to screw from the bottom the spacers to mount an pcb etc.

I hate metalworking in all aspects My drilling holes always looks awful.

My drilling holes always looks awful.

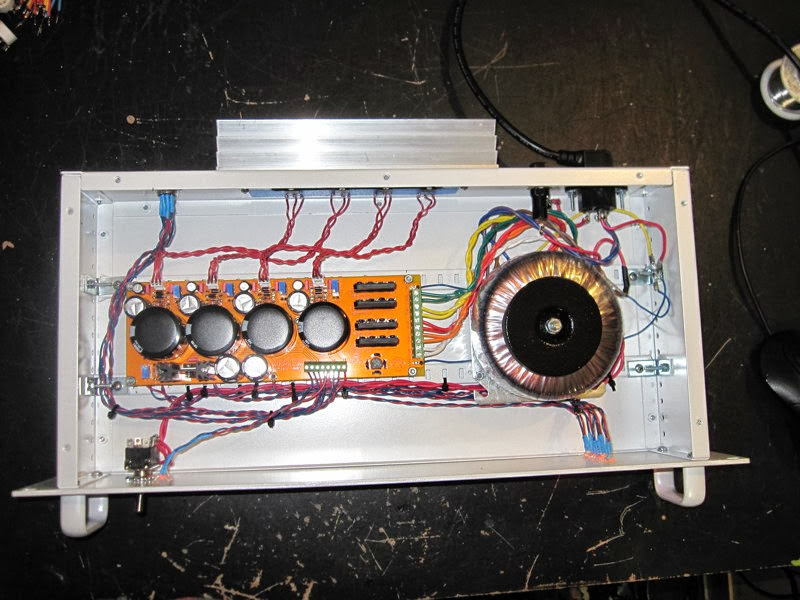

I found an very good solution!

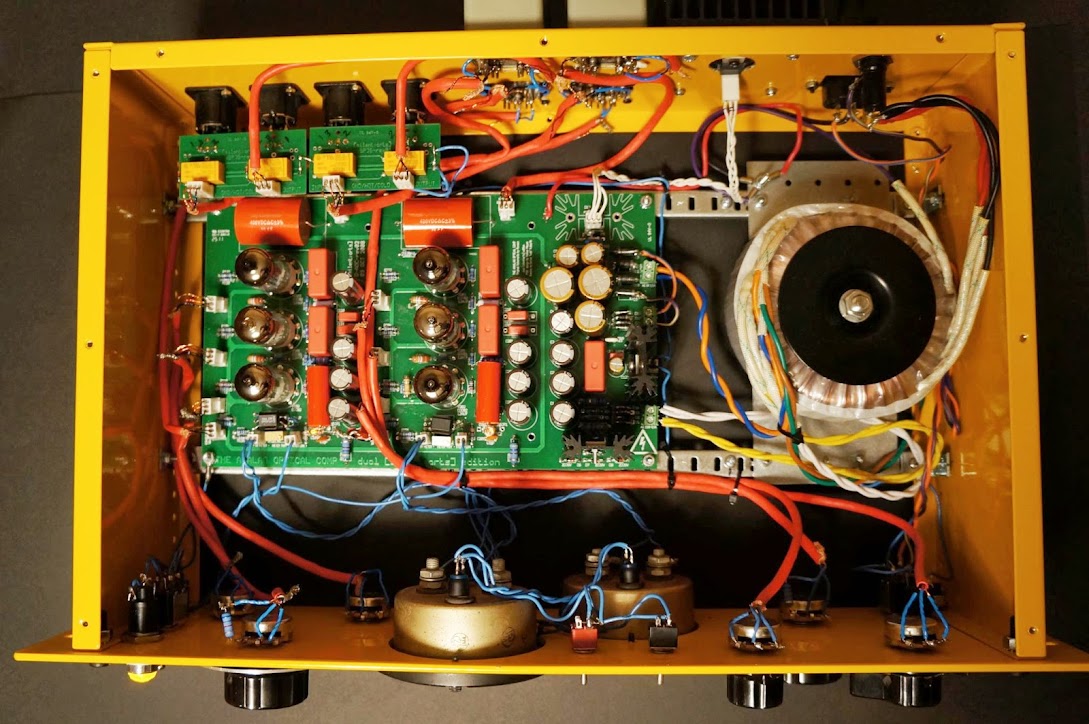

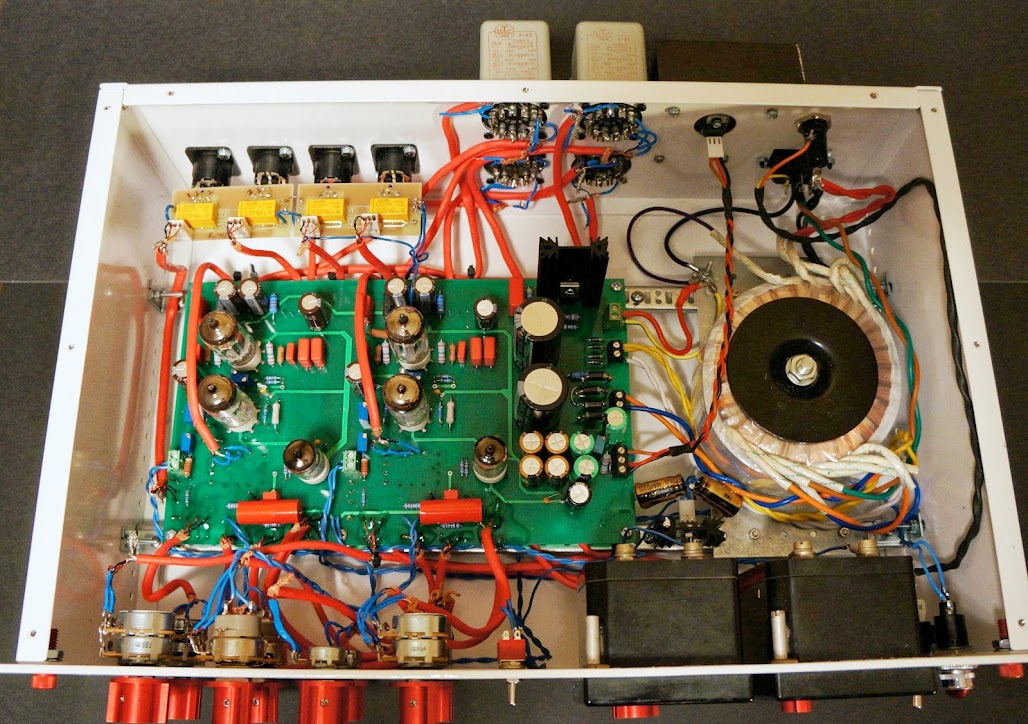

Epoxy-metal glue commonly known as "liquid metal".

Effect is very good, looks nice, it is strong, it has electrical connectivity and it is cheap.

First i attached spacers to the pcb to have perfect spacing, then i used the glue to the bottom of the spacers, little pressed to the housing - few hours and it's great effect

I always drill housings to screw from the bottom the spacers to mount an pcb etc.

I hate metalworking in all aspects

I found an very good solution!

Epoxy-metal glue commonly known as "liquid metal".

Effect is very good, looks nice, it is strong, it has electrical connectivity and it is cheap.

First i attached spacers to the pcb to have perfect spacing, then i used the glue to the bottom of the spacers, little pressed to the housing - few hours and it's great effect