Hello all,

I've been lurking for quite some time, soaking up the vast amount of knowledge that this board has to offer. So before I begin, I thank all of you very much.

I've been running a somewhat respectable recording studio out of my house for pretty much a decade, mainly focused on drum tracking. My first intro to DIY was acoustic treatment, and I found the learning, planning, and constructing process very rewarding. Electronic circuitry has always intimidated me, but about a year ago I stumbled across Classic API's website (which led me here), and the thought of DIY gear intrigued me. My API 3124 is what made me learn mic placement; there's one knob, and if it doesn't sound awesome, then it isn't the preamps fault: go fix your placement. I have a love for API gear, and wanted to build my own.

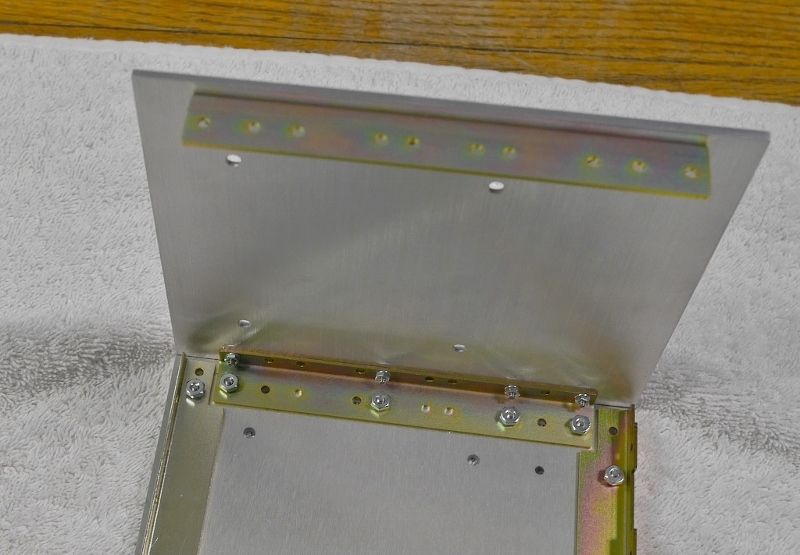

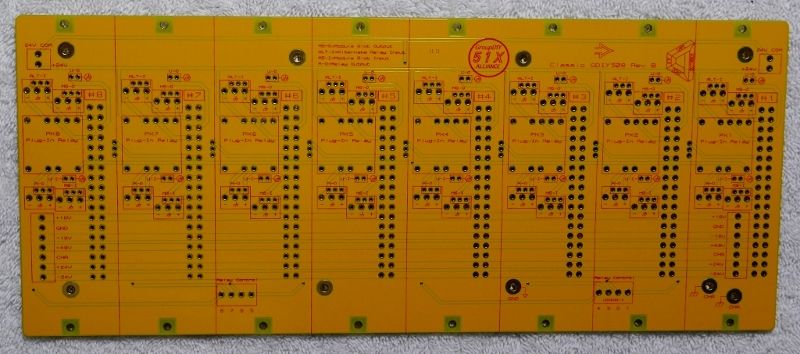

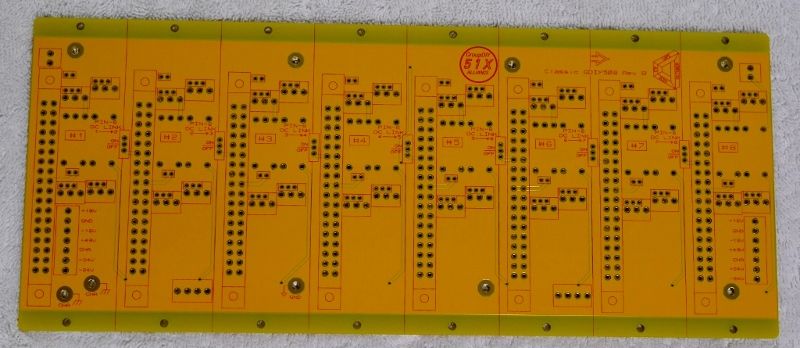

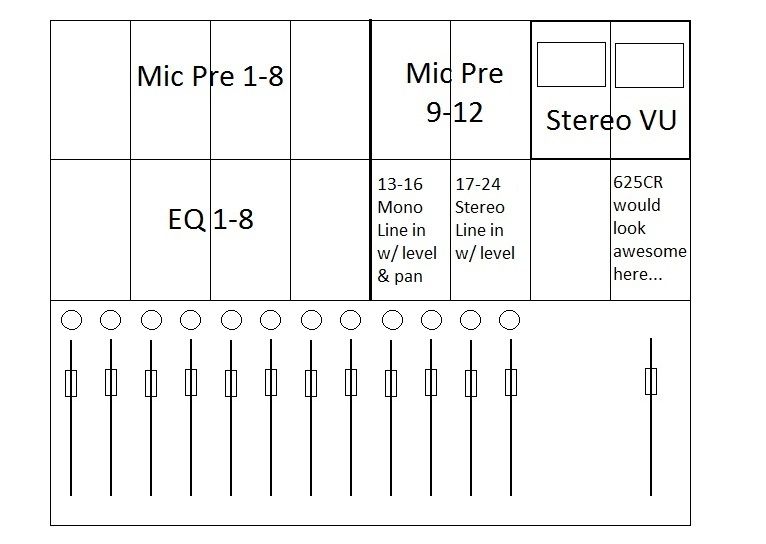

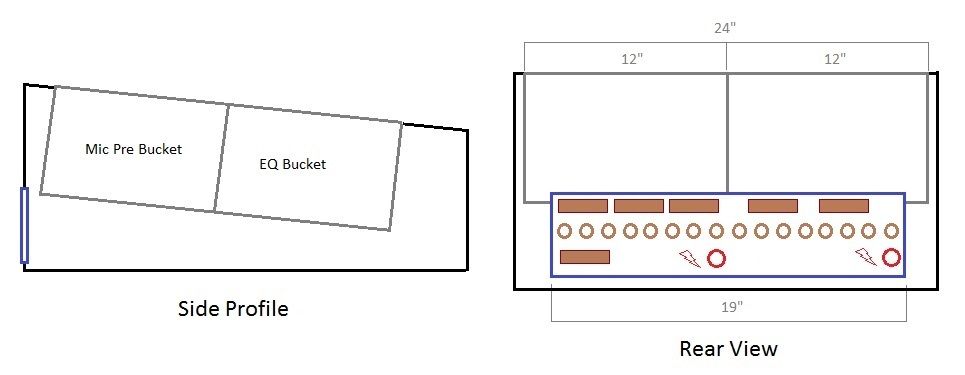

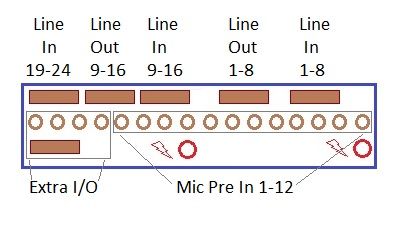

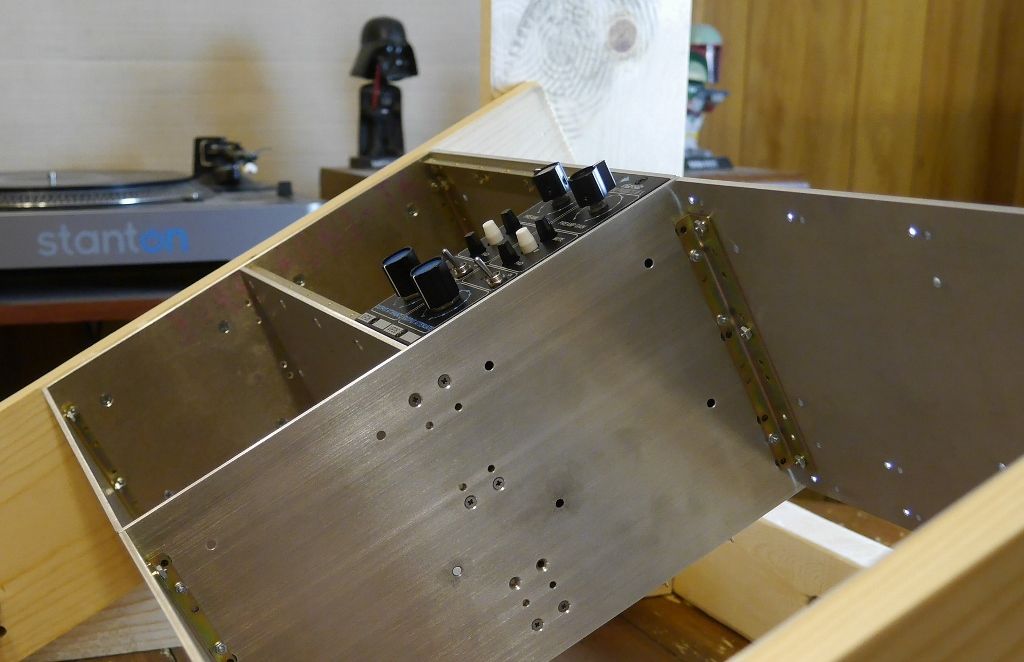

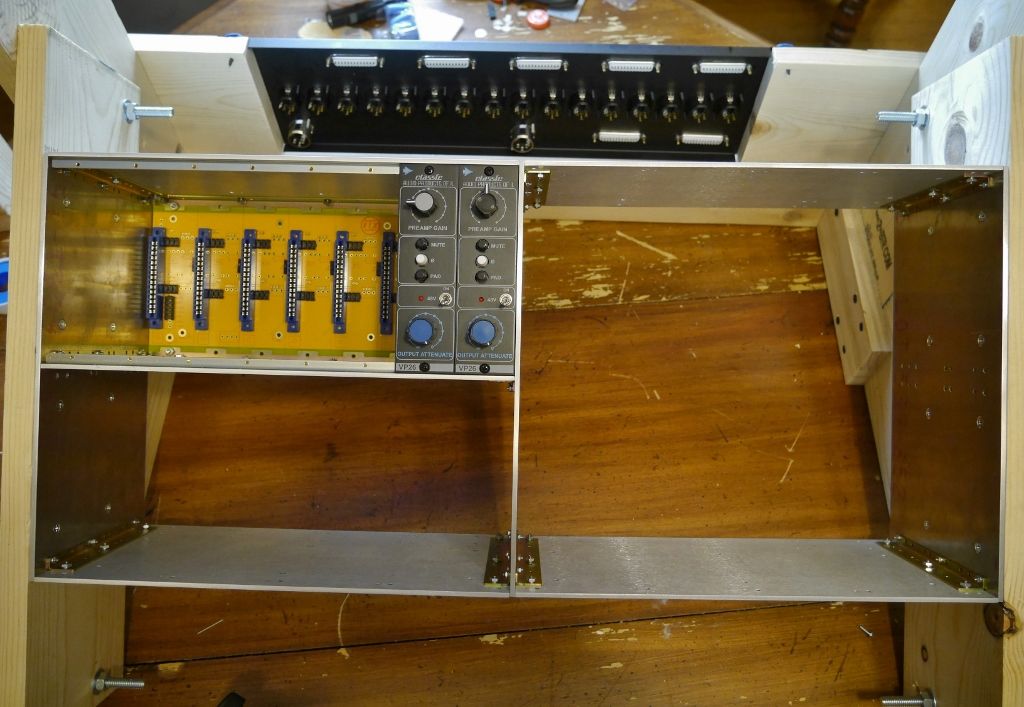

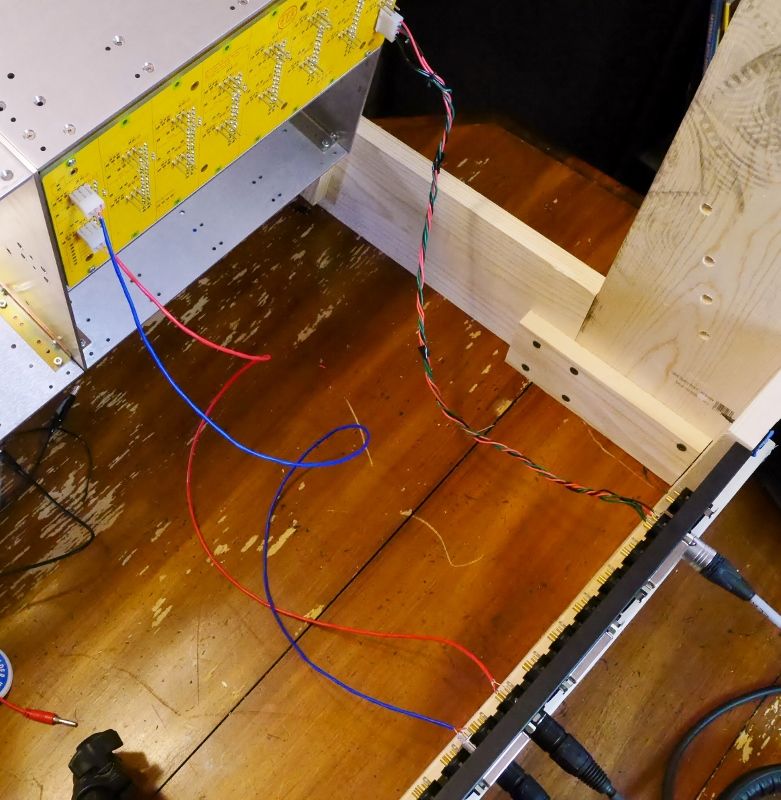

I've always lusted after an API console, having been afforded the opportunity to play with the first 1608 delivered at IV Labs in Chicago. Realizing a full console is a long way off, I need to start somewhere. Wanting to get into the 500 series format, there's the obvious choice of the GDIY 511 rack, an all in one package that even a noob such as myself could assemble, thanks to Chunger's build threads. But then there's Jeff's 500 series modular console monster thread; after reading through that several dozen times, I concluded the Classic API/GDIY 508 rack system was where I would start, even if I would have to actually figure out I/O connections and some sort of support structure for it on my own.

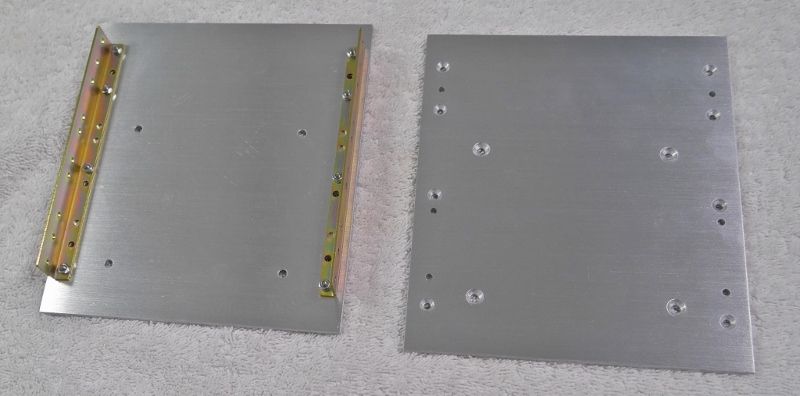

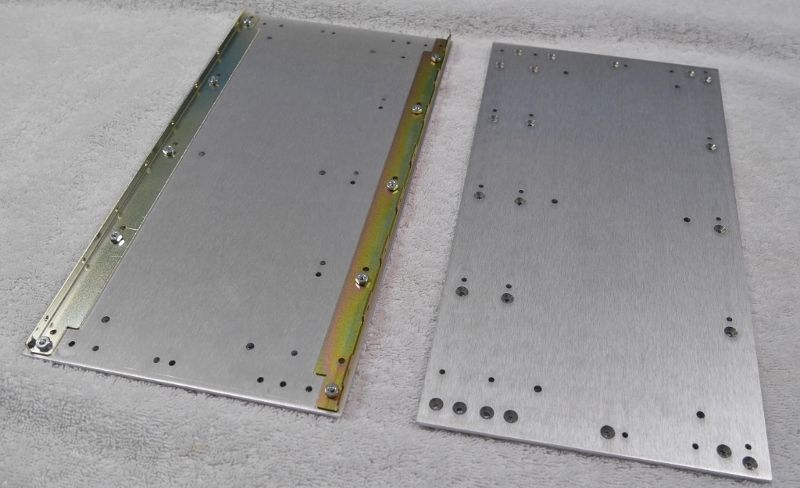

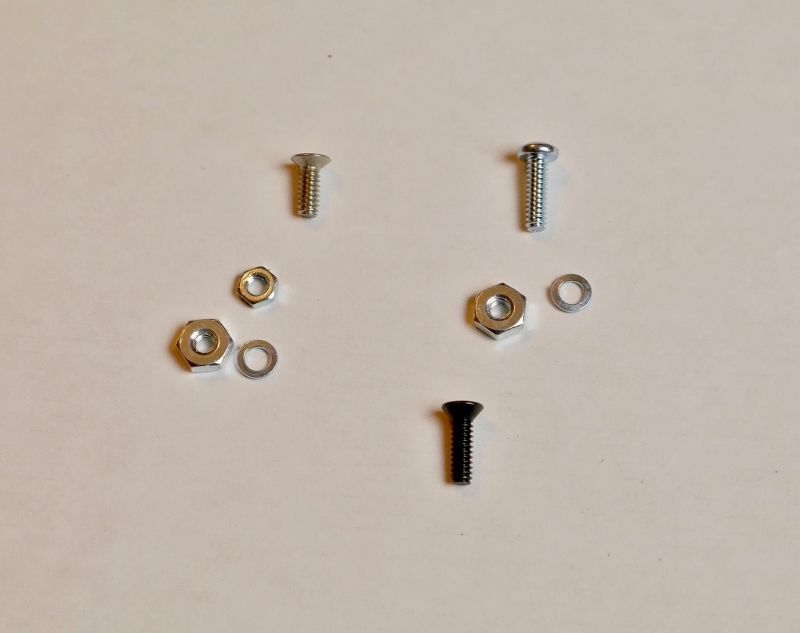

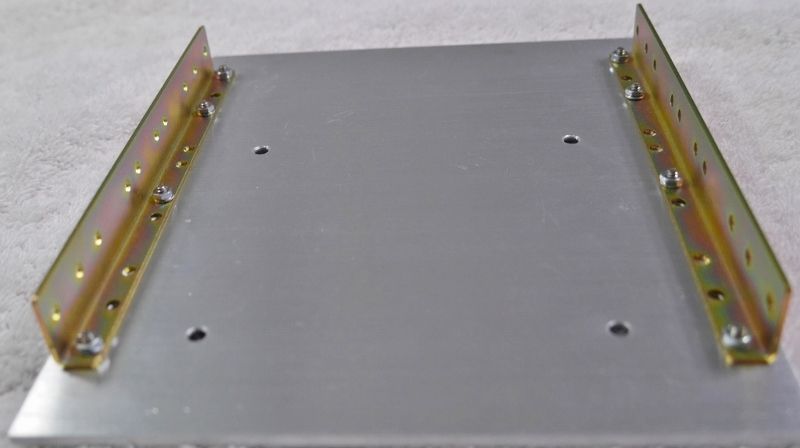

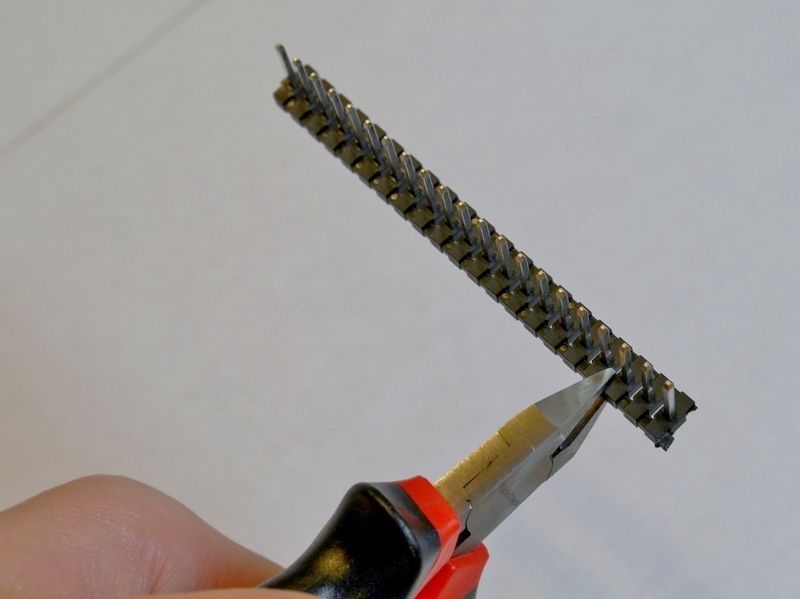

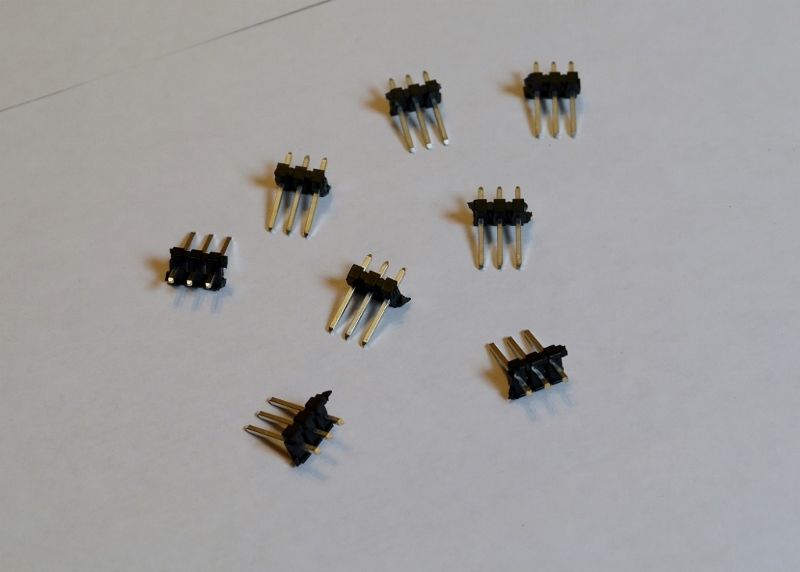

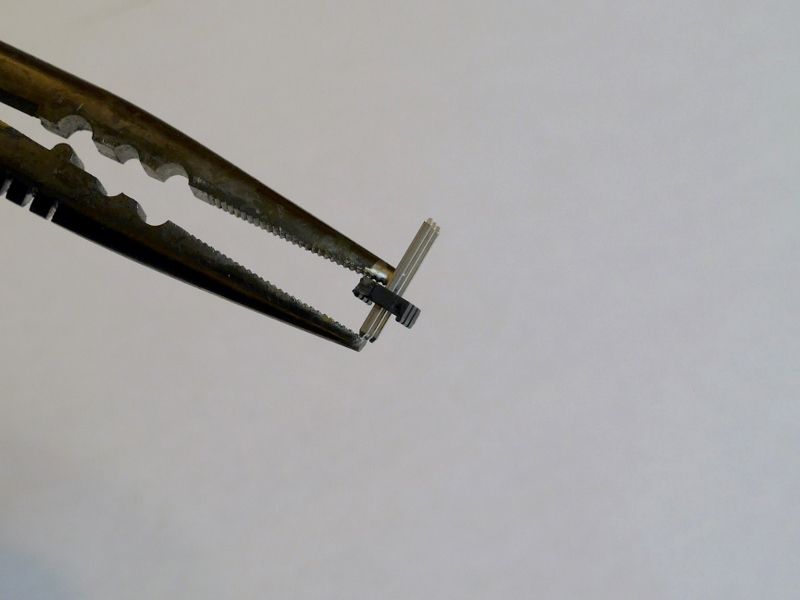

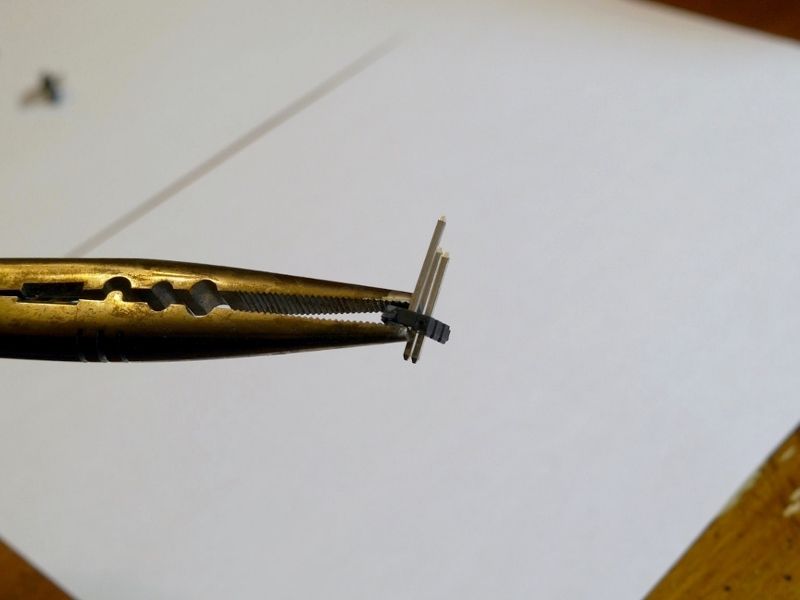

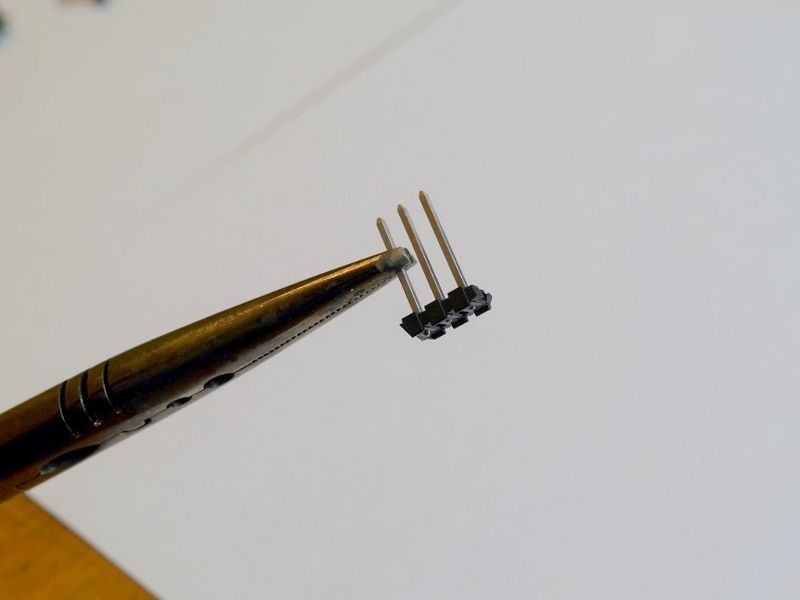

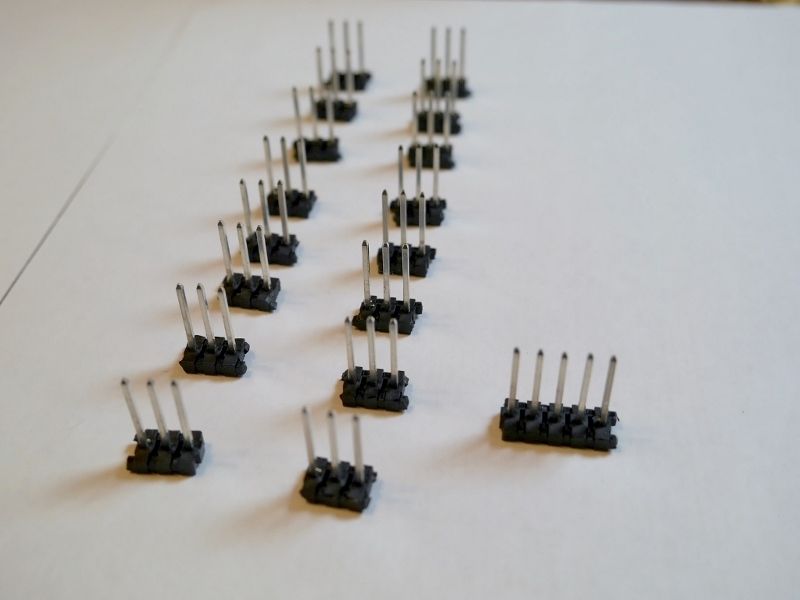

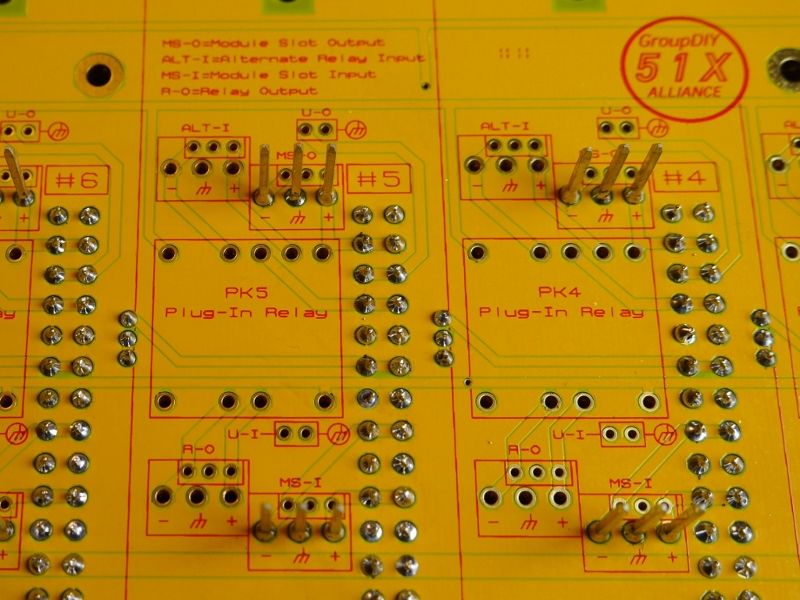

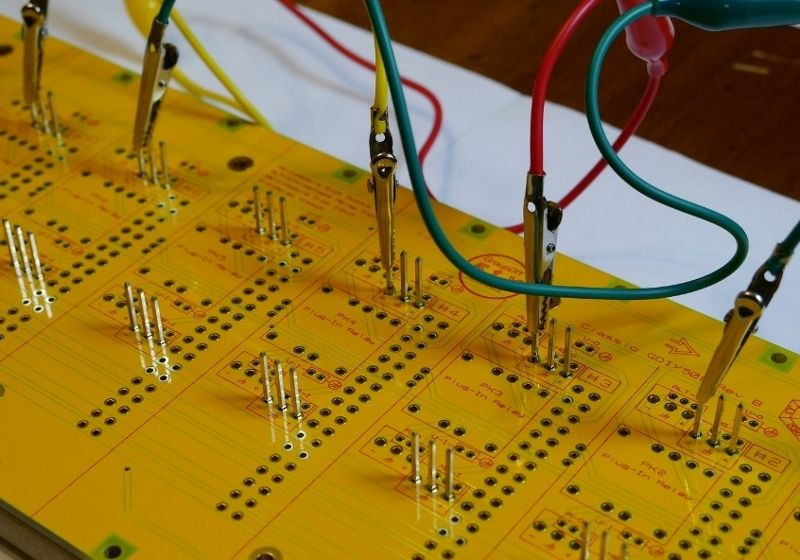

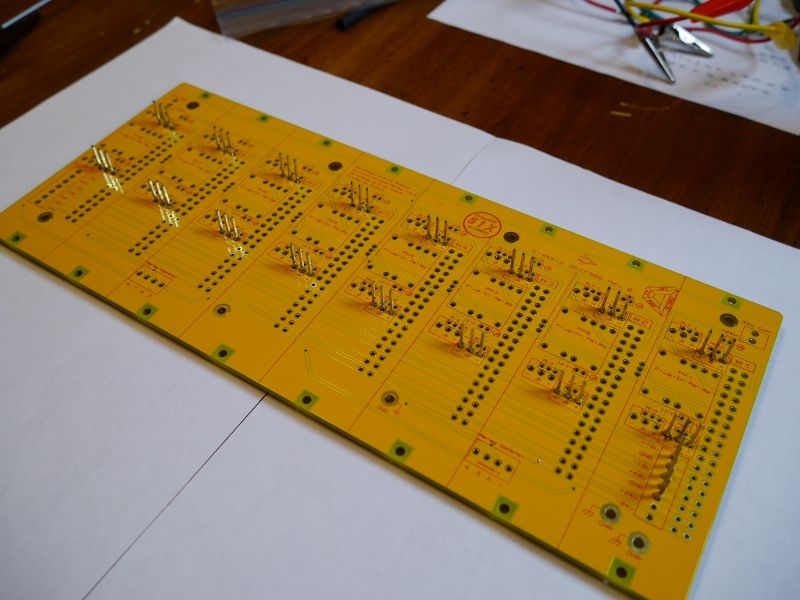

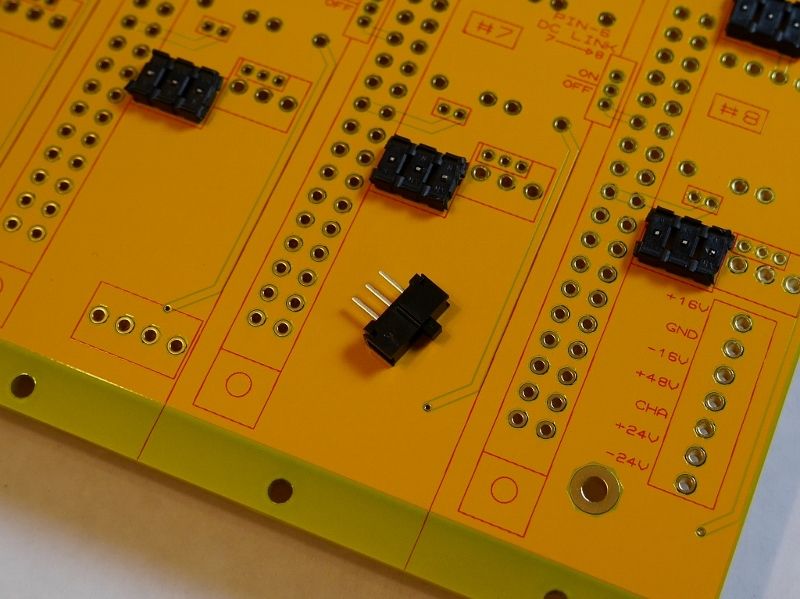

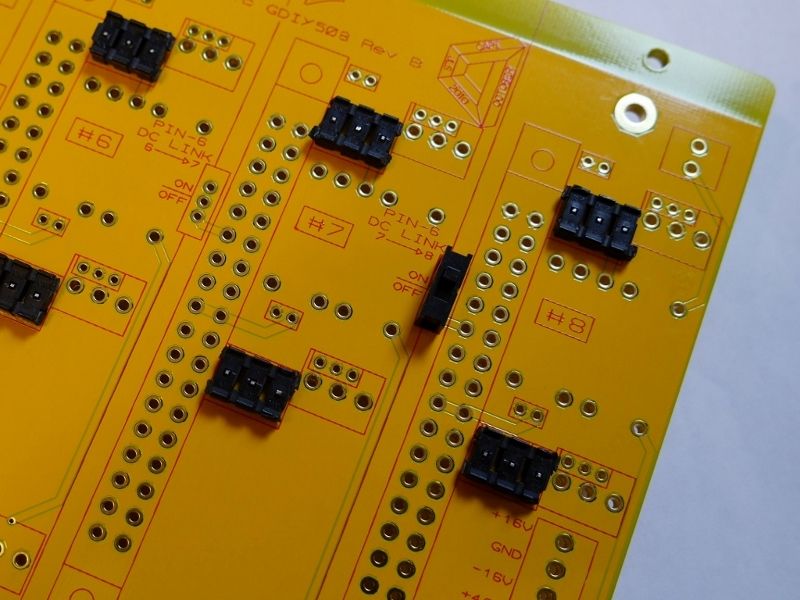

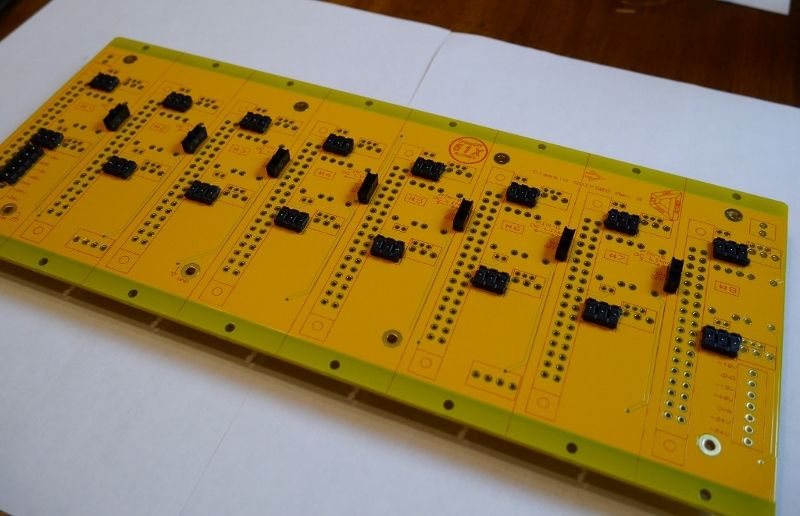

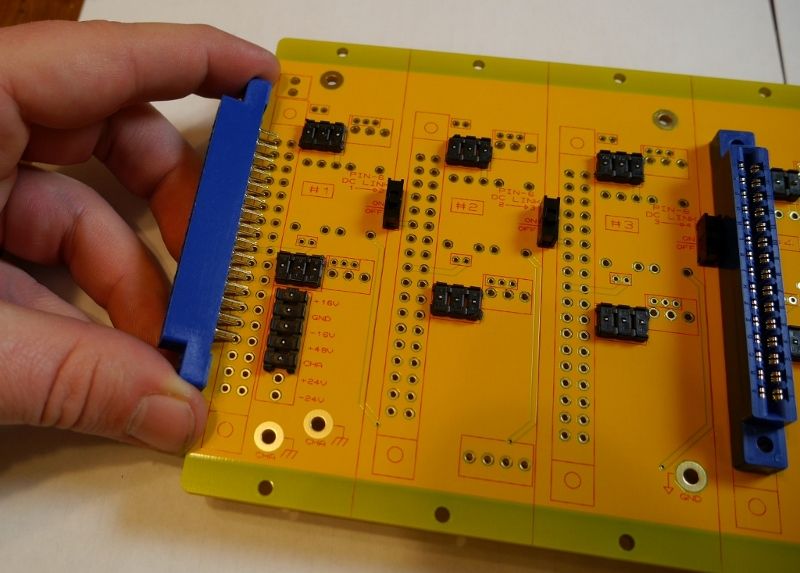

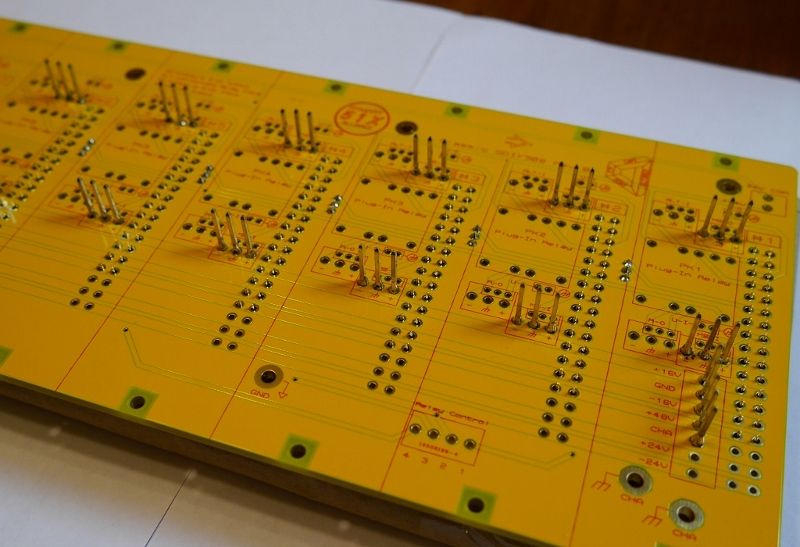

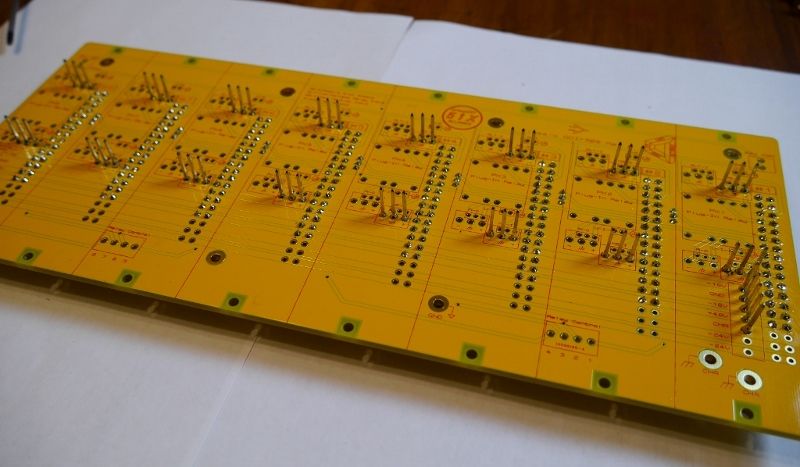

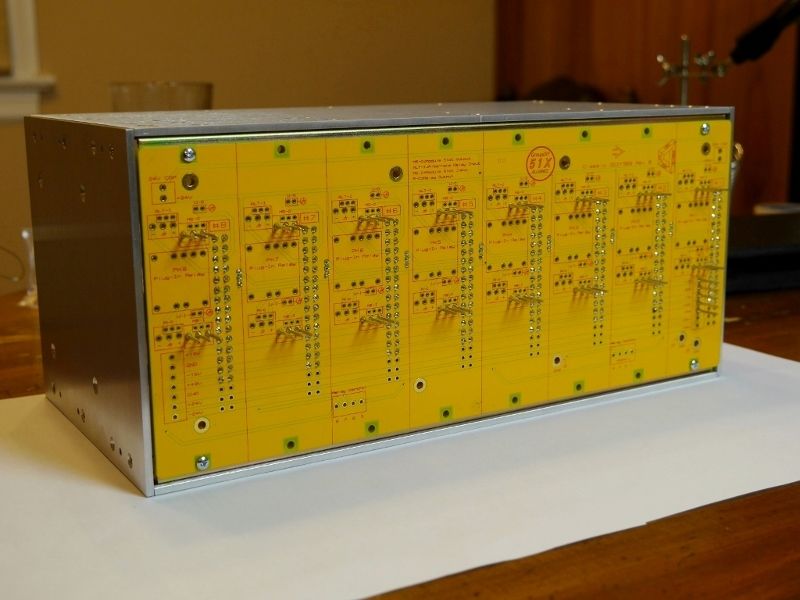

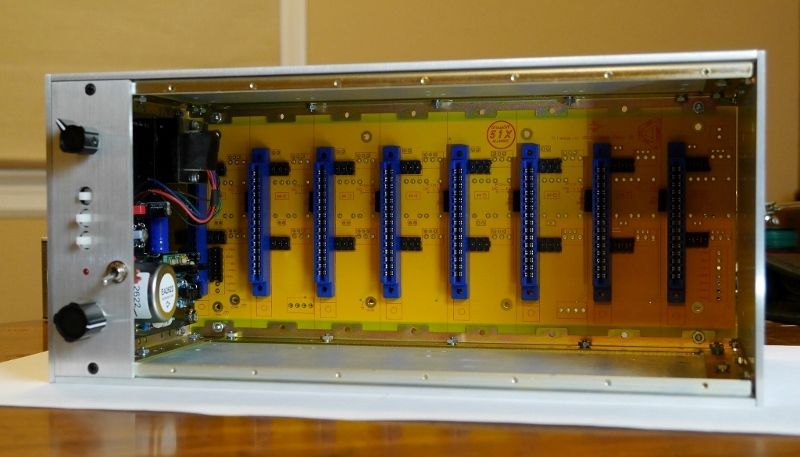

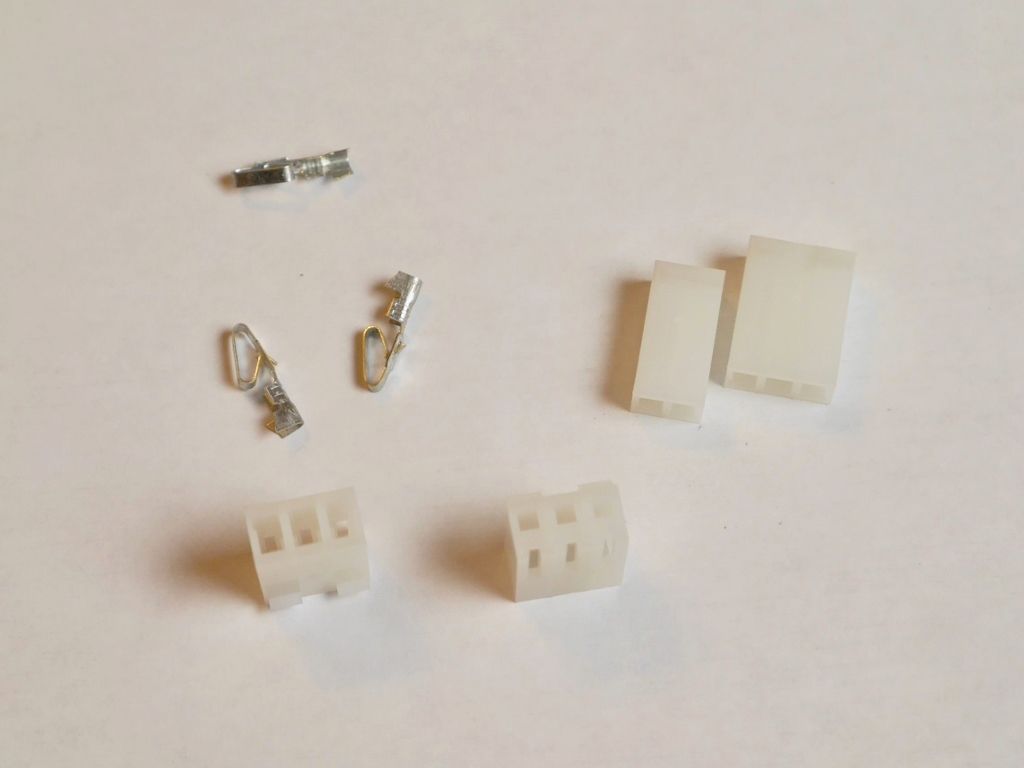

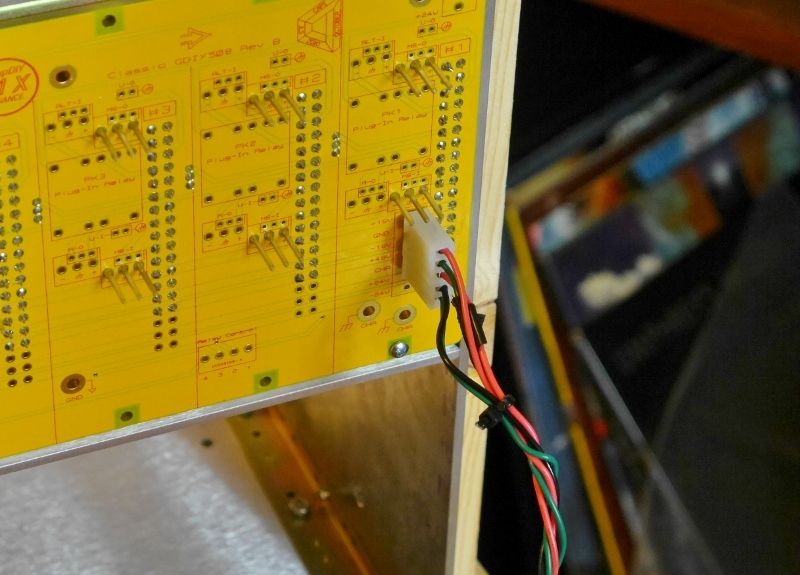

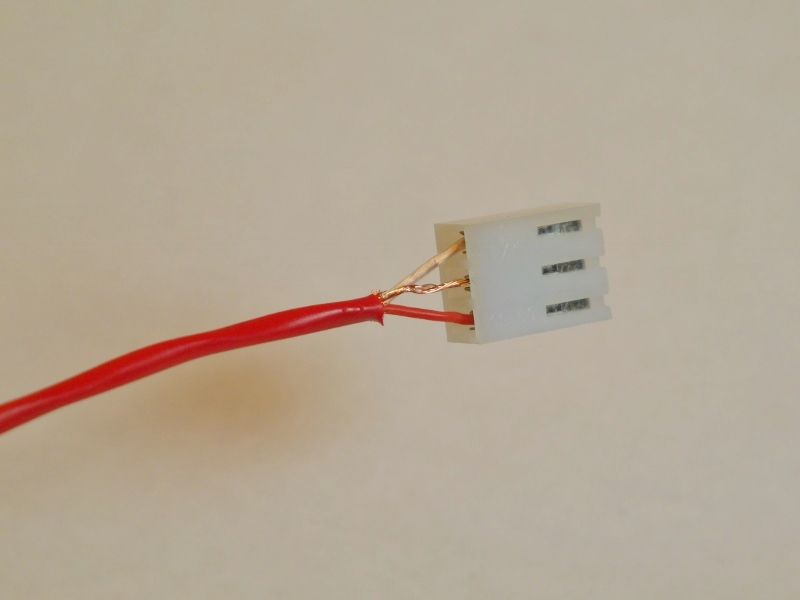

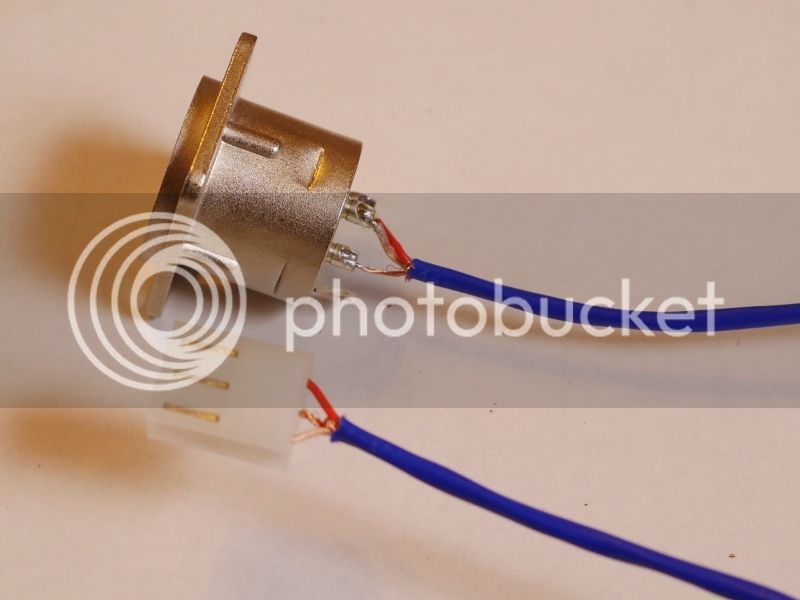

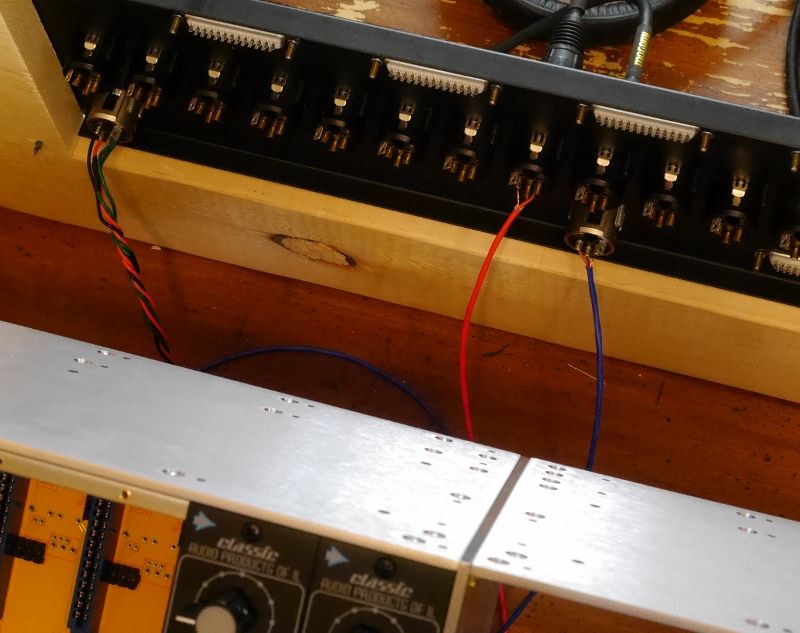

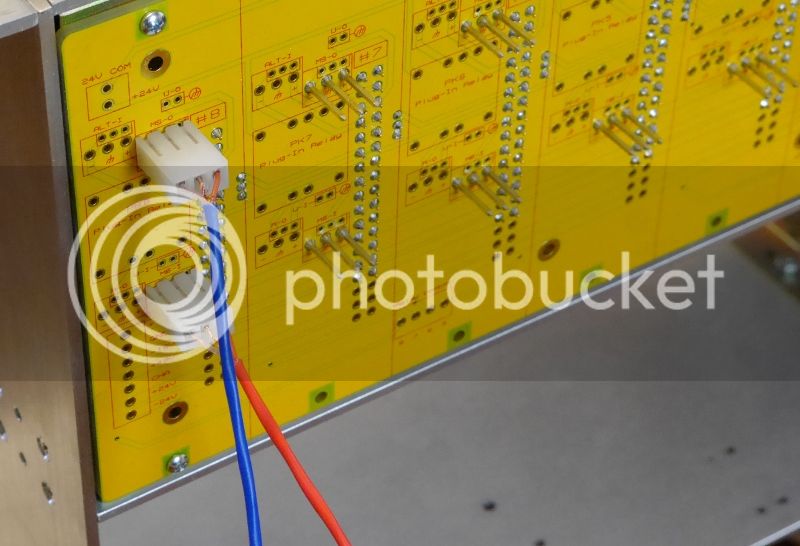

The next couple posts will be photo logs of the Classic API single 508 rack bucket and backplane build, followed by next steps. I figured photodocumenting the build would maybe help other noobs out (a la Chunger's great work) and hopefully allow people to red flag anything I'm doing wrong... like I said, still a noob.

Also, I'm going to have tons of questions.

Keith

I've been lurking for quite some time, soaking up the vast amount of knowledge that this board has to offer. So before I begin, I thank all of you very much.

I've been running a somewhat respectable recording studio out of my house for pretty much a decade, mainly focused on drum tracking. My first intro to DIY was acoustic treatment, and I found the learning, planning, and constructing process very rewarding. Electronic circuitry has always intimidated me, but about a year ago I stumbled across Classic API's website (which led me here), and the thought of DIY gear intrigued me. My API 3124 is what made me learn mic placement; there's one knob, and if it doesn't sound awesome, then it isn't the preamps fault: go fix your placement. I have a love for API gear, and wanted to build my own.

I've always lusted after an API console, having been afforded the opportunity to play with the first 1608 delivered at IV Labs in Chicago. Realizing a full console is a long way off, I need to start somewhere. Wanting to get into the 500 series format, there's the obvious choice of the GDIY 511 rack, an all in one package that even a noob such as myself could assemble, thanks to Chunger's build threads. But then there's Jeff's 500 series modular console monster thread; after reading through that several dozen times, I concluded the Classic API/GDIY 508 rack system was where I would start, even if I would have to actually figure out I/O connections and some sort of support structure for it on my own.

The next couple posts will be photo logs of the Classic API single 508 rack bucket and backplane build, followed by next steps. I figured photodocumenting the build would maybe help other noobs out (a la Chunger's great work) and hopefully allow people to red flag anything I'm doing wrong... like I said, still a noob.

Also, I'm going to have tons of questions.

Keith