Dumbascii

Active member

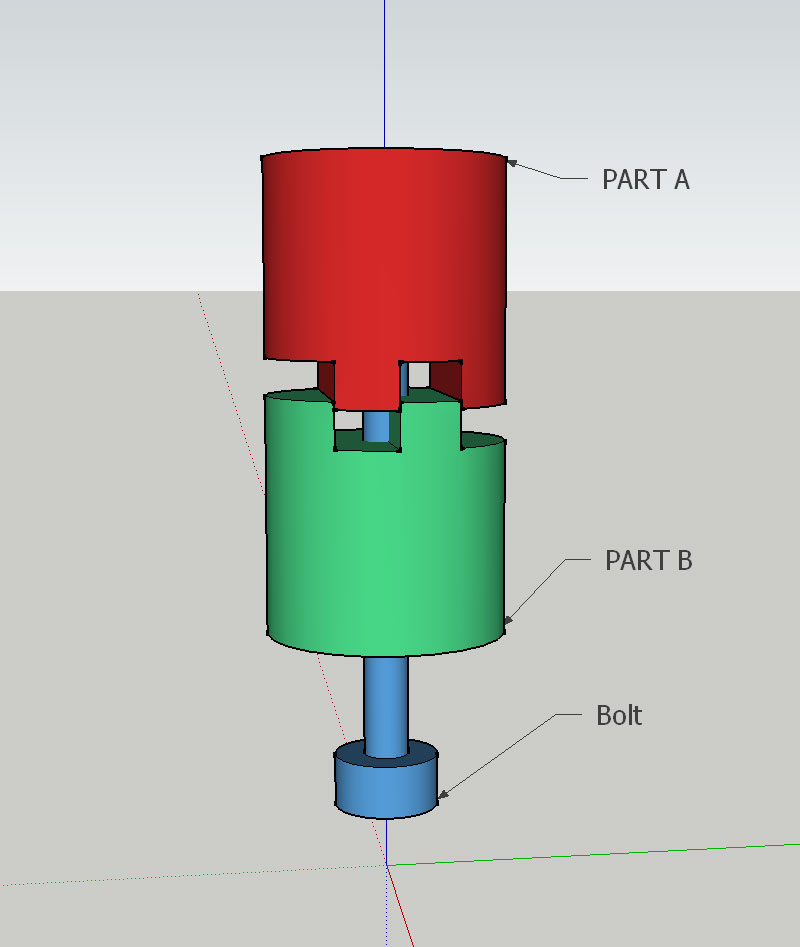

Can you imagine a simpler way to do this? I can imagine a couple of other ways, but they are many machining steps such as pinning or keying. Seems that I'm missing the obvious answer.

Imagine that PART A is a 5/8"-27 threaded stub as would screw into a microphone clip. PART B is say the end of a steel bar. When A & B are attached together with the Bolt, A & B absolutely must not rotate even if the bolt is only finger tight. Plain friction isn't good enough, like if the cylinder faces were flat and the Bolt was tight.

Thanks!

Imagine that PART A is a 5/8"-27 threaded stub as would screw into a microphone clip. PART B is say the end of a steel bar. When A & B are attached together with the Bolt, A & B absolutely must not rotate even if the bolt is only finger tight. Plain friction isn't good enough, like if the cylinder faces were flat and the Bolt was tight.

Thanks!

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)