sahib

Well-known member

Hi Ian,

Please see attached sketch.

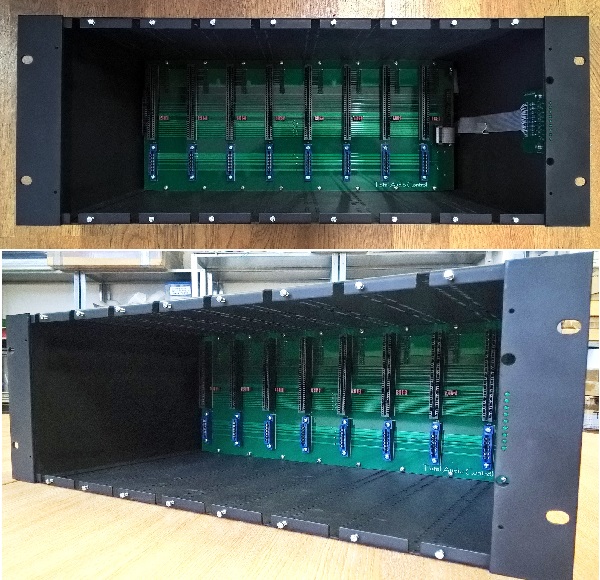

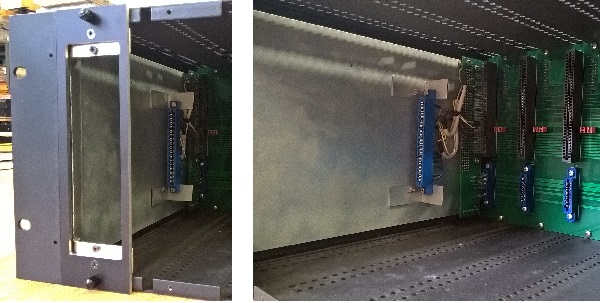

You would normally be interested in the distance B, which is from the front face of the rack (or the rear face of the module front panel) to the insertion depth of the card edge connector.

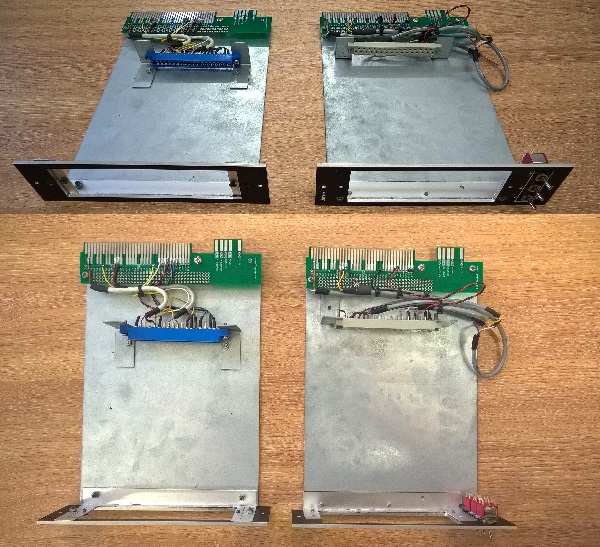

However, based on the 500 depth and the existing card edge connector, the distance A is 155.27. We can have this to be variable. I have dumped my previous method of making it as there is a simpler way by using spacers which are mounted onto the connector panel. Varying the height of the spacers we can vary the depth of the edge connector backplane.

Simple question is, what would you like the distance A to be?

On the other hand, since we are not using the type of connector used in Eurorack how are you going to reconcile with that?

Edit: I have also ordered the sample for a 72 way card edge connector. It has much smaller pitch, hence overall length and much higher DC withsanding voltage (1000VDC) and contact current rating (16A @25 degreesC).

Please see attached sketch.

You would normally be interested in the distance B, which is from the front face of the rack (or the rear face of the module front panel) to the insertion depth of the card edge connector.

However, based on the 500 depth and the existing card edge connector, the distance A is 155.27. We can have this to be variable. I have dumped my previous method of making it as there is a simpler way by using spacers which are mounted onto the connector panel. Varying the height of the spacers we can vary the depth of the edge connector backplane.

Simple question is, what would you like the distance A to be?

On the other hand, since we are not using the type of connector used in Eurorack how are you going to reconcile with that?

Edit: I have also ordered the sample for a 72 way card edge connector. It has much smaller pitch, hence overall length and much higher DC withsanding voltage (1000VDC) and contact current rating (16A @25 degreesC).