gar381 said:

Gary's tant replacement rules...

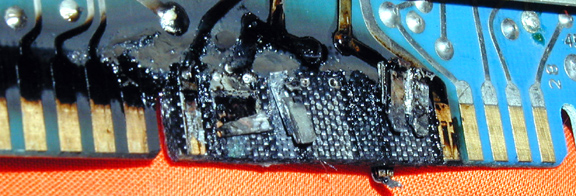

Replace ALL Tants across power rails unless you like fires. :'(

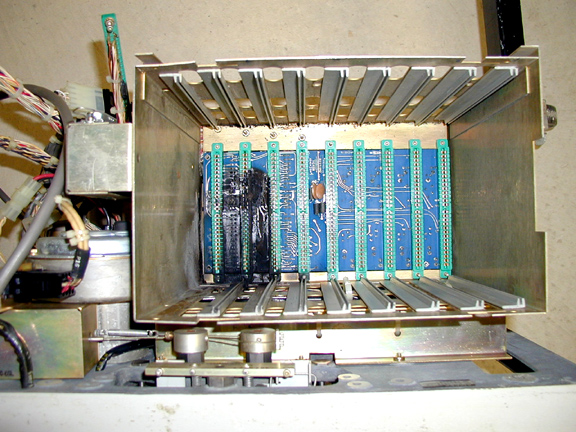

I'll disagree with this, but only for specific situations. The Eventide H3000 that I recently rebuilt was properly designed with Ta power supply bypasses because the box ran _so_ hot that there was no hope that any wet Al electrolytic, even modern ones, would survive for more than a few years. They used quality 25V solid Ta caps for a 15V rail, and that would have worked with essentially no safety margin, except when the linear regulator failed and dumped 20V onto the +15rail, causing the 25V Ta caps to short.

The simple thing to do is to replace the 25V Ta caps with 35V parts, which will probably withstand 20V, and will most certainly withstand 15V.

The basic rule with solid Ta caps is to 'de-rate' them appropriately. If you want a cap to work with let's say a 15V rail, you need to use 2x that voltage or more. So, there aren't 30V Ta caps, but they do make 35V caps, so those are good. 25V caps will probably work, but they're at the ragged edge already, so if you want few failures, 25V caps are not a good idea for 15V rails. 2x de-rating is a good rule, and it will prevent many fires.

Current spikes will also kill solid Ta caps, so if there is any chance of uncontrollably large currents through a bypass or coupling cap, one should not use a Ta cap. Caps that drive external connectors are also susceptible to this - if that jack were shorted or subjected to odd external voltages, this may cause the Ta cap to fail.

These applications are very troublesome to me, and I agree with you that if one wants to avoid fires, do not use solid Ta caps where they could be subject to external voltages or impedances that are not well controlled. Inside of a circuit, they can work well, but this is not the case if they are exposed to external nodes.