Making a CNC has been on my wishlist for some time now.

I make fender-tweed-style guitar amp cabinets (and finished amplifiers) and sell them online. Currently, I do it old fashioned way, by using regular tools in my workshop, but it's just too time consuming.

Also, it would be nice if I could make aluminum engraved plates, enclosure and other stuff for DIY.

I wondered what would be a good design for carving multiple medium sized pieces of wood simultaneously and precision milling and engraving of aluminum. So it must be big enough for woodwork, yet rigid and precise enough to make fine engravings on aluminum.

The machine has to have at least 150cm x 90cm working surface, perhaps more - as long as it doesn't compromise the precision.

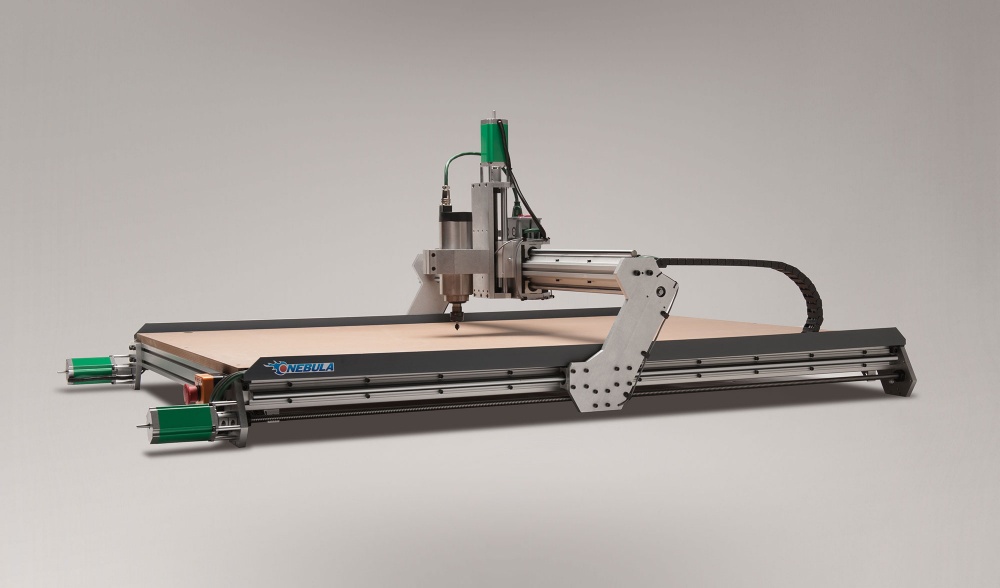

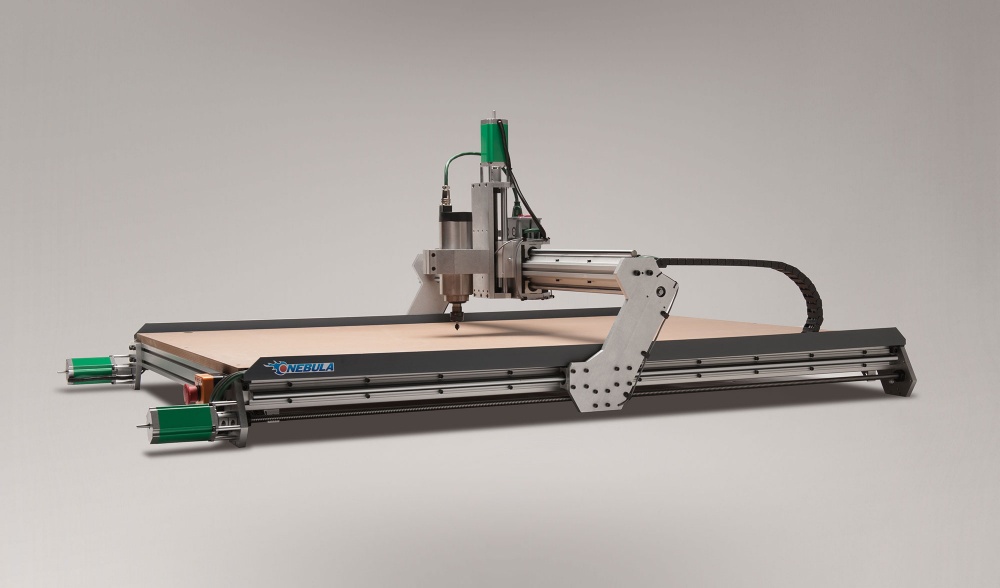

I did some research, and I was thinking about ripping off Probotix Nebula. It seems like a pretty straightforward design with minimum of custom parts. (which I could make out of thick plywood for the prototype, and then machine them out of aluminum once the machine is finished ;D ).

It uses ballscrews and supported rails for maximum rigidity.

I could spend 1.5-2k euro on parts, considering I already have a ton of 4x8cm aluminum extrusions, and some smaller ones (also not including spindle,PC, dust extraction).

Any other suggestions?

I make fender-tweed-style guitar amp cabinets (and finished amplifiers) and sell them online. Currently, I do it old fashioned way, by using regular tools in my workshop, but it's just too time consuming.

Also, it would be nice if I could make aluminum engraved plates, enclosure and other stuff for DIY.

I wondered what would be a good design for carving multiple medium sized pieces of wood simultaneously and precision milling and engraving of aluminum. So it must be big enough for woodwork, yet rigid and precise enough to make fine engravings on aluminum.

The machine has to have at least 150cm x 90cm working surface, perhaps more - as long as it doesn't compromise the precision.

I did some research, and I was thinking about ripping off Probotix Nebula. It seems like a pretty straightforward design with minimum of custom parts. (which I could make out of thick plywood for the prototype, and then machine them out of aluminum once the machine is finished ;D ).

It uses ballscrews and supported rails for maximum rigidity.

I could spend 1.5-2k euro on parts, considering I already have a ton of 4x8cm aluminum extrusions, and some smaller ones (also not including spindle,PC, dust extraction).

Any other suggestions?