ruffrecords

Well-known member

Not sure where to put this so here goes.

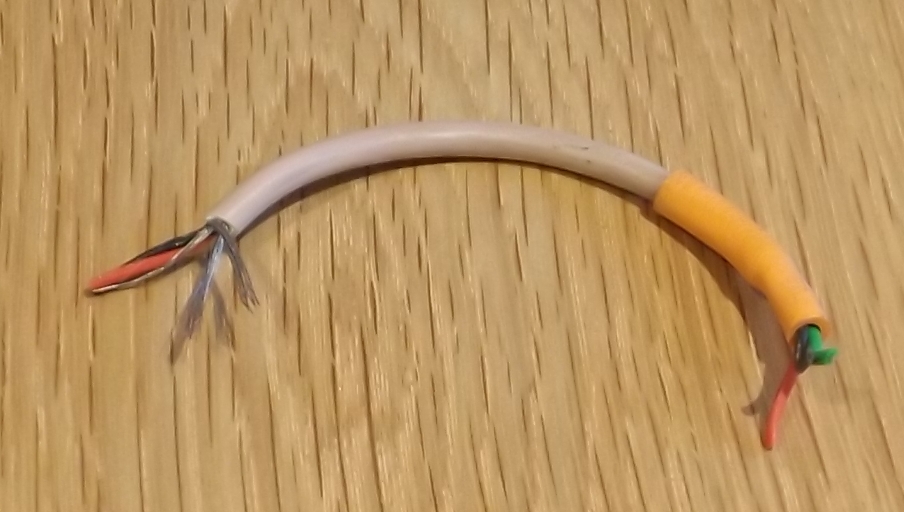

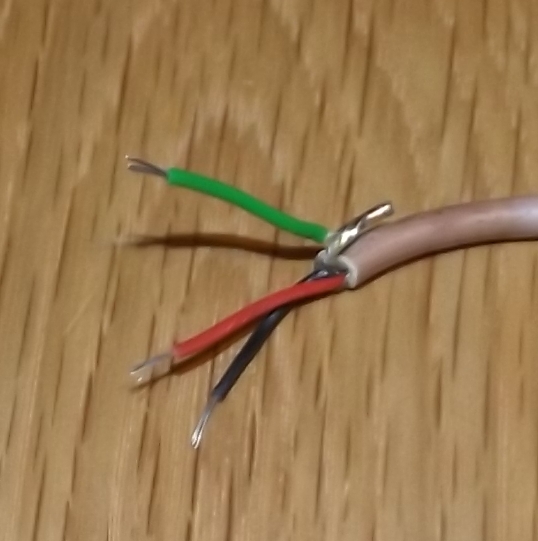

There is a proper technique for terminating the screens of audio cables with a separate wire so they can be connect to crimp connectors, for example, where soldering the screen is inappropriate or simply not possible. I am sure we used to call these pigtails at Neve back in the 70s. Anyway, I have googled myself silly trying to find a description of how to do this properly but I cannot find it.

Anyone know?

Cheers

Ian

There is a proper technique for terminating the screens of audio cables with a separate wire so they can be connect to crimp connectors, for example, where soldering the screen is inappropriate or simply not possible. I am sure we used to call these pigtails at Neve back in the 70s. Anyway, I have googled myself silly trying to find a description of how to do this properly but I cannot find it.

Anyone know?

Cheers

Ian