boji

Well-known member

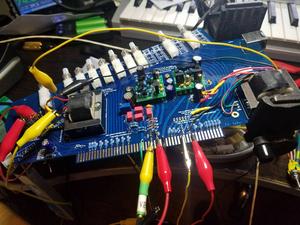

So...good news, I alligator clipped up my console's proto left card and from input to direct out passes audio and is nice and quiet (whew, that's a milestone and a relief).

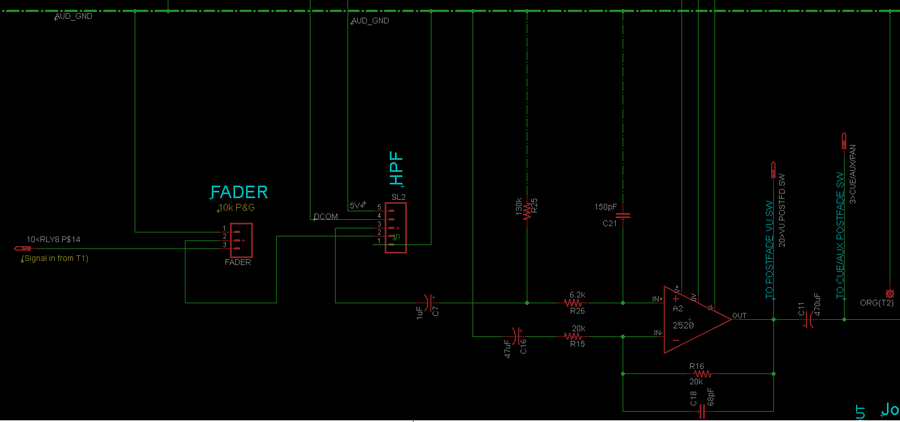

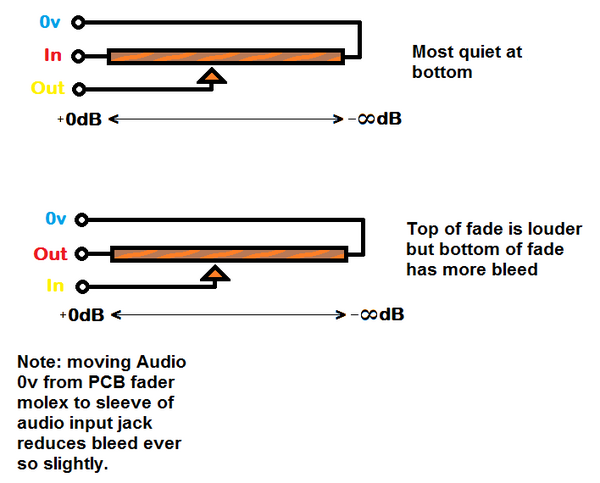

One thing I'm noticing is the old 10k P&G I'm using attenuates well, but doesn't bring the input down all the way silent.

I should mention the faders are from the 80's and definitely need new bushings. Of course rocking the slider perpendicular to its natural course of action it makes the volume blip in and out, but when I keep the contacts on the strip with a fair amount of pressure, I can still hear some of the signal. Is this normal / why we have a mute button?