boji

Well-known member

Wow thanks NM, very helpful. I appreciate your time and input.

chassis a separate shield, wholly independent of all circuits was the cleanest way to isolate channels uniformly. HA...to return to JR's metaphor about sewer pipe poo and dirty sink water, perhaps I'm needlessly making my sewer pipe out of gold or something?!?

So, to restate and summarize my primary concern: there isn't impedance or crosstalk issues to worry about with two AGND planes near each other sinking different audio information?

I think you've been trying to dispel that myth for me from the beginning?

(I should mention I will be running agnd and pgnd bus bars per 8 channels under the console to maximize low impedance.)

Frankly this is my first serious attempt at making some PCB's. Forgive me for running on high-school physics level instincts here, and I know there's plenty of design history that proves what works and what doesn't. =/

Where long traces ran the length of the board, I replaced their endpoints with thru-hole pads, and will bridge them with wire that is shielded.I don't really understand what "shielded freewire points" are ?

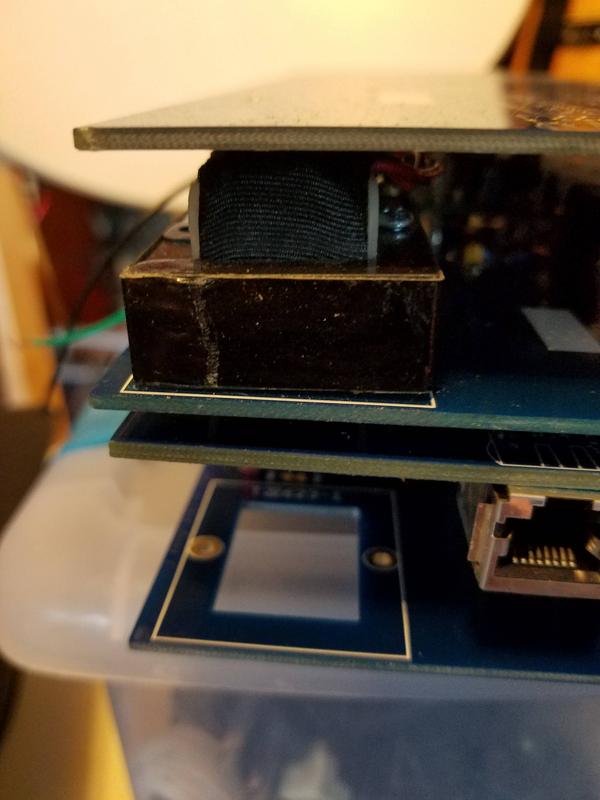

Maybe chassis pour is the wrong name for it. It was primarily meant to shield any stray emr from adjacent transformers, since they are geometrically on axis with each other (EDIT: see photo in subsequent post) and the pcb cutout square where the bobbin is recessed means the card adjacent to the tx is what would 'shield' between channels."And I still don't get why you want to put a 'Chassis Pour' on a pcb ?"

I suppose I have an incorrect running assumption that there may be slight differences in potential between adjacent card audio 0V since their will be differences in audio channel information. I figured"An 'AGND pour' will attenuate crosstalk between channels. As will any Copper area held at a low impedance fixed potential eg a voltage rail - but 0V is usually easily available and offers other electrical benefits."

So, to restate and summarize my primary concern: there isn't impedance or crosstalk issues to worry about with two AGND planes near each other sinking different audio information?

I think you've been trying to dispel that myth for me from the beginning?

(I should mention I will be running agnd and pgnd bus bars per 8 channels under the console to maximize low impedance.)

Frankly this is my first serious attempt at making some PCB's. Forgive me for running on high-school physics level instincts here, and I know there's plenty of design history that proves what works and what doesn't. =/