Bo Deadly

Well-known member

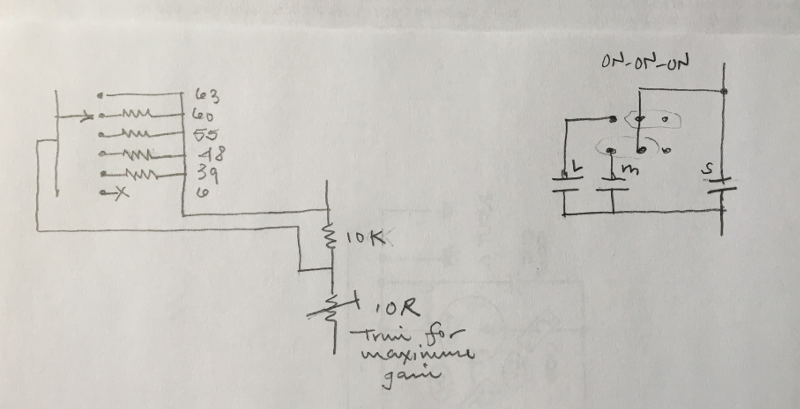

Is it possible to use a smaller cap in the gain control to low-cut in a Complementary Feedback Pair circuit?

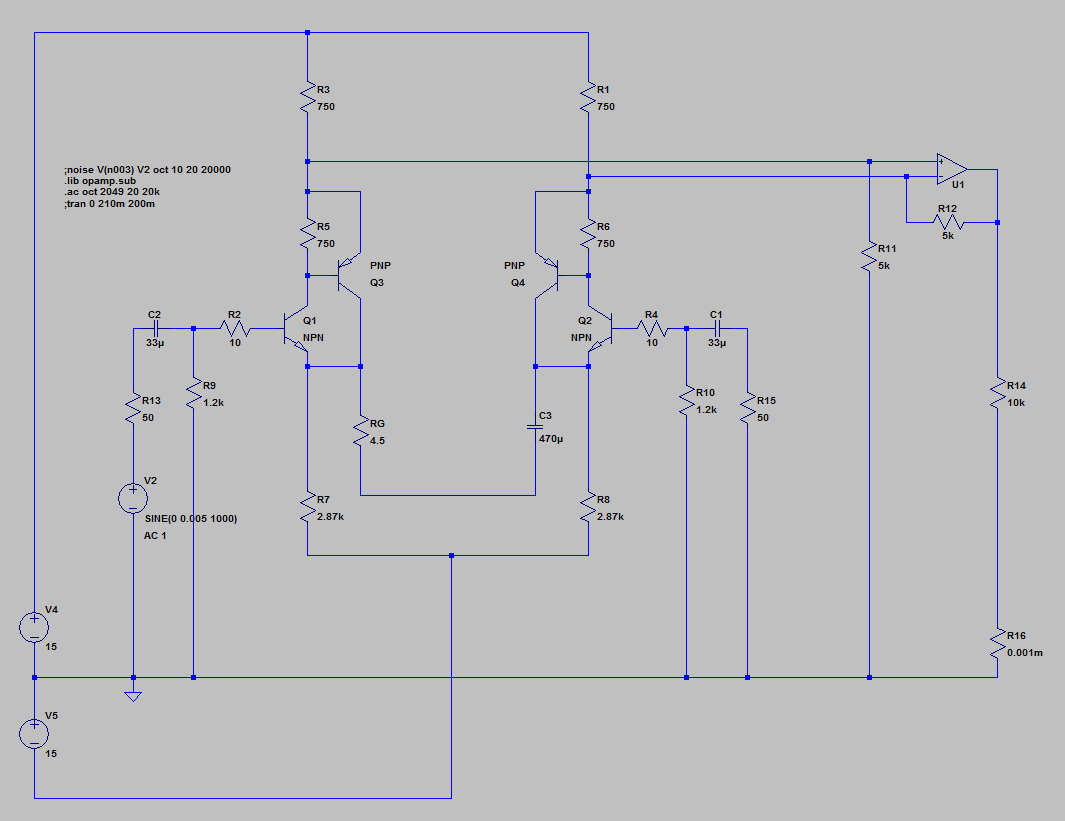

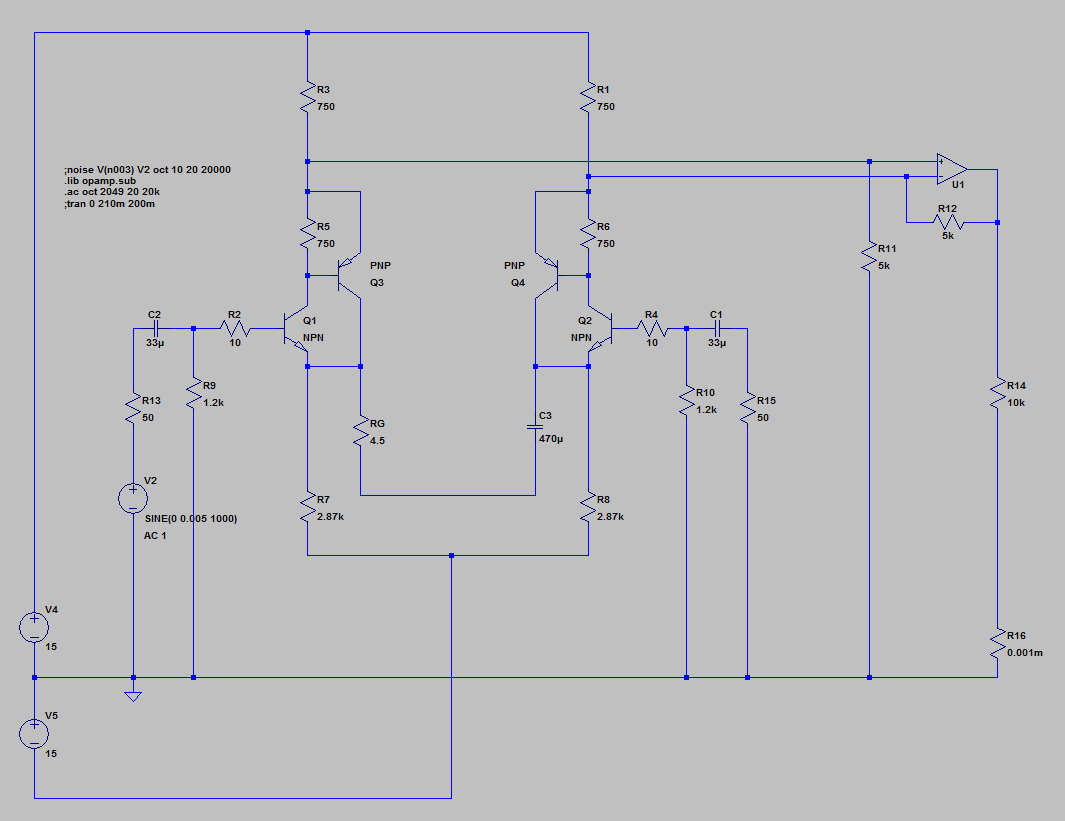

Here's my simplified circuit (model attached renamed .asc to .txt):

The THAT datasheets recommend large caps like 3300u with low values of Rg so as not to loose low frequencies. But simulations suggest that 470u is suitable with the smallests values of Rg.

My immediate though is that distortion would be an issue with an electrolytic. To get to 200Hz would require ~150uF. Would a tantalum work?

Also, is the noise gain a concern here?

Here's my simplified circuit (model attached renamed .asc to .txt):

The THAT datasheets recommend large caps like 3300u with low values of Rg so as not to loose low frequencies. But simulations suggest that 470u is suitable with the smallests values of Rg.

My immediate though is that distortion would be an issue with an electrolytic. To get to 200Hz would require ~150uF. Would a tantalum work?

Also, is the noise gain a concern here?