After couple of years making various Fender-style clones, cabs etc I finally decided to start making my own transformers.

My tube audio adventure started with a 5f1 Champ clone, so why not start with OPT for this small but legendary amp. It seems to be easy enough.

I'll post some questions and my progress in this thread.

I have this recipe from vaacumbrain.uk (CJ)

Step one: get all the parts. I will be ordering from ascocomponents. I've already contacted them, they are willing to sell me some sample for my prototype.

They don't seem to have El-50 and 12.7mm bobbin like described in the recipe, so I'll take El-48 and 16mm bobbin instead.

Lamination material would be 0.5mm non grain oriented steel.

2 gauges of copper wire: 24ga and 35ga.

Step two: building the transformer.

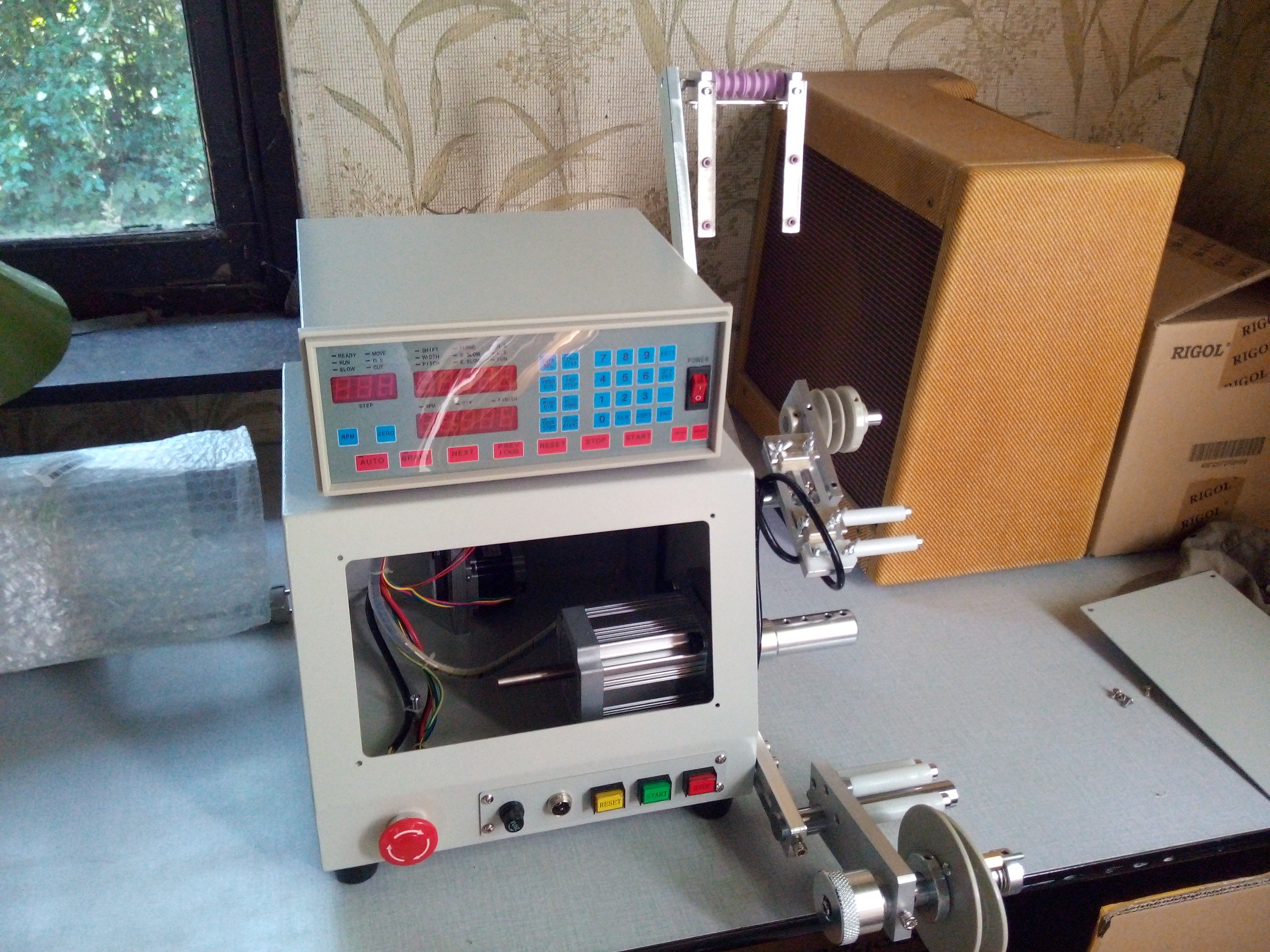

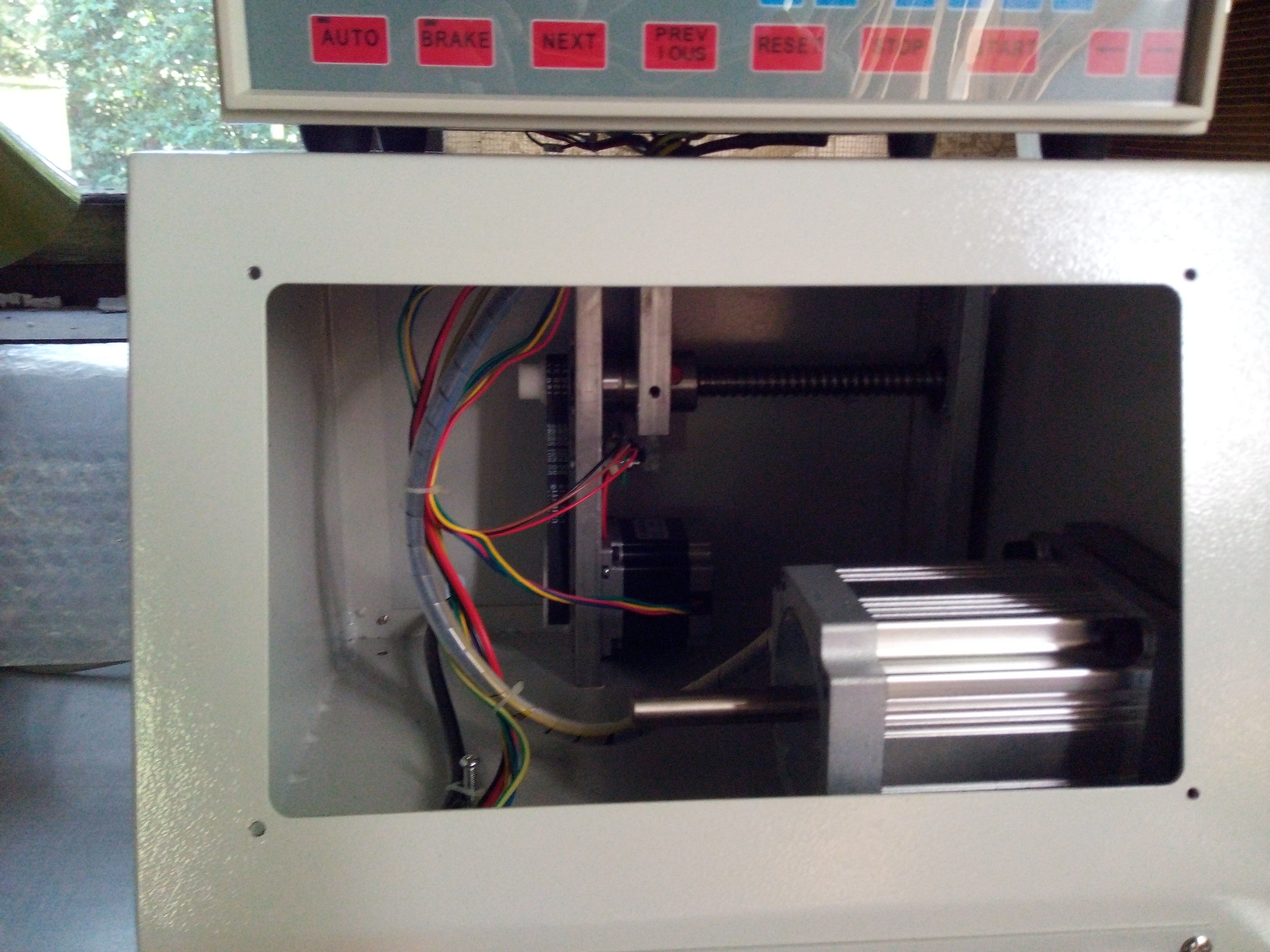

I have a CNC coil winder. I will start by winding 2988 turns of 35ga wire for the primary, then some isolation tape, then winding 69 turns of 25ga wire for the secondary, then isolation tape.

Strip the isolation from the enamelled wire ends, solder some thicker wire, use some shrink tube, then securing the wires with more isolation tape.

At this point the coil could be dipped in varnish (which one would you recommend?), but would it be okay to skip this step for the prototype, since it would be easier to recycle materials, if something is wrong?

Then put the lams inside and put the U clamp on.

Or should it be dipped in varnish after the transformer is fully assembled? Or maybe both?

That should be it. Please correct me if I'm wrong.

My tube audio adventure started with a 5f1 Champ clone, so why not start with OPT for this small but legendary amp. It seems to be easy enough.

I'll post some questions and my progress in this thread.

I have this recipe from vaacumbrain.uk (CJ)

Step one: get all the parts. I will be ordering from ascocomponents. I've already contacted them, they are willing to sell me some sample for my prototype.

They don't seem to have El-50 and 12.7mm bobbin like described in the recipe, so I'll take El-48 and 16mm bobbin instead.

Lamination material would be 0.5mm non grain oriented steel.

2 gauges of copper wire: 24ga and 35ga.

Step two: building the transformer.

I have a CNC coil winder. I will start by winding 2988 turns of 35ga wire for the primary, then some isolation tape, then winding 69 turns of 25ga wire for the secondary, then isolation tape.

Strip the isolation from the enamelled wire ends, solder some thicker wire, use some shrink tube, then securing the wires with more isolation tape.

At this point the coil could be dipped in varnish (which one would you recommend?), but would it be okay to skip this step for the prototype, since it would be easier to recycle materials, if something is wrong?

Then put the lams inside and put the U clamp on.

Or should it be dipped in varnish after the transformer is fully assembled? Or maybe both?

That should be it. Please correct me if I'm wrong.