boji

Well-known member

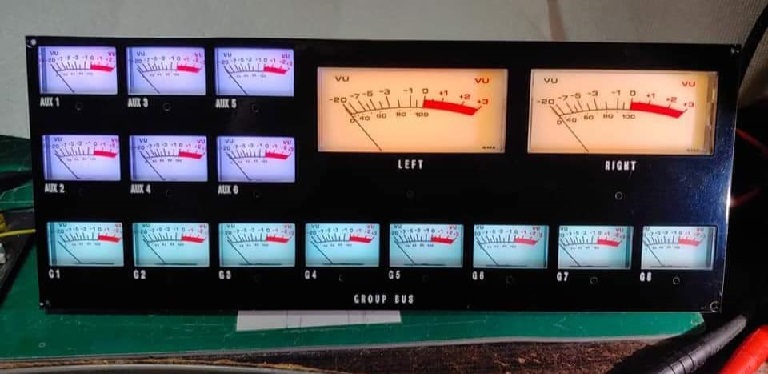

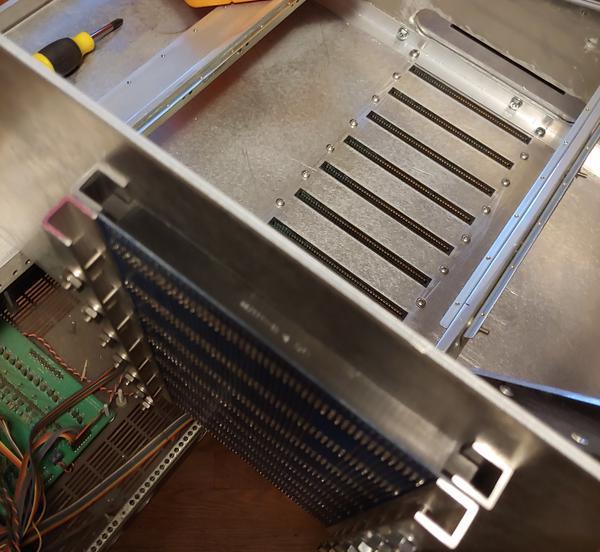

Been putting off posting about this project for too long. Figure some updates are better than none. Posts will not be in order of completion, since if I run across some older stuff, this is where it'll go. Suppose this will be the completion thread too....roughly estimated to be 6-10 months from now.

Original sourcing for project and 1604 schema transcription began here: Console signal flow, input cards, general discussion on API styled DIY mixer

(Thanks to members for uploading what you could)

A note on GDIY:

Thanks for everyone's help in seeing this thing to completion. A few of you took the time to look over my schematics, pointing out concerns or potential issues. The discussions on how to manage grounds was fantastic. There's been at least 100 other conversations since the beginning where I opened a thread up out of ignorance or confusion, only to receive generous and thoughtful responses that almost always amplified my knowledge around the topic, and often took paths that led to questions I didn't even know were in need of asking!

Truly, there's no place like gdiy.

-Boji

Original sourcing for project and 1604 schema transcription began here: Console signal flow, input cards, general discussion on API styled DIY mixer

(Thanks to members for uploading what you could)

A note on GDIY:

Thanks for everyone's help in seeing this thing to completion. A few of you took the time to look over my schematics, pointing out concerns or potential issues. The discussions on how to manage grounds was fantastic. There's been at least 100 other conversations since the beginning where I opened a thread up out of ignorance or confusion, only to receive generous and thoughtful responses that almost always amplified my knowledge around the topic, and often took paths that led to questions I didn't even know were in need of asking!

Truly, there's no place like gdiy.

-Boji

Last edited: