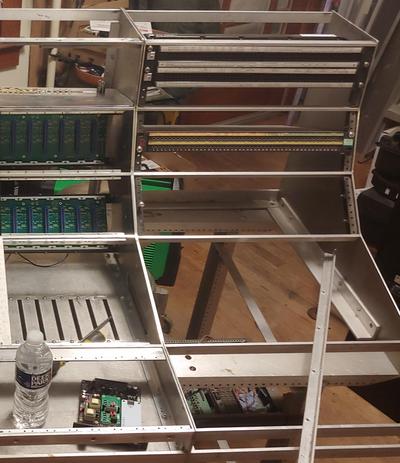

boji

Well-known member

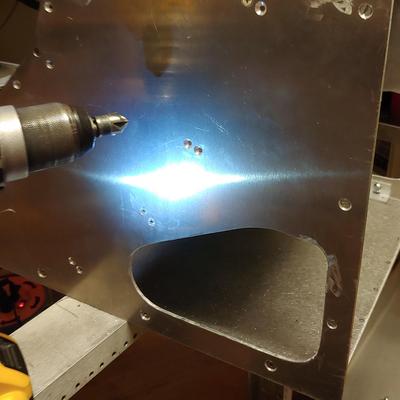

Small update-- After mixed results using a brake for backplane brackets, going to instead try the brazing route. Picts to follow after stuff arrives and I've got acquainted with the process.

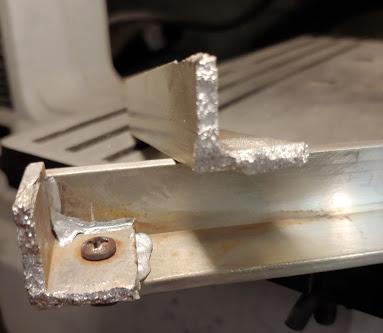

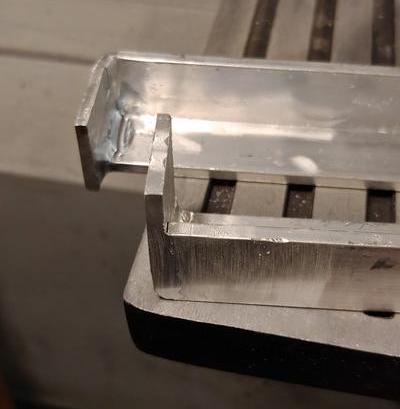

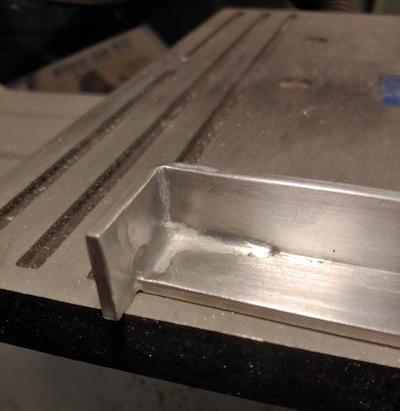

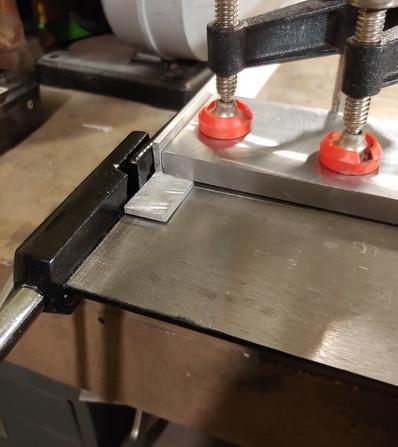

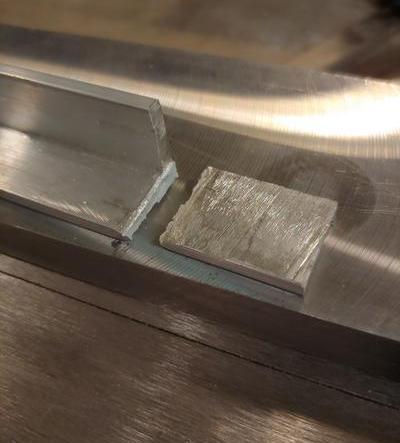

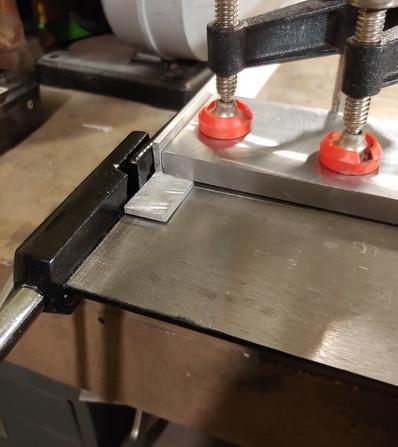

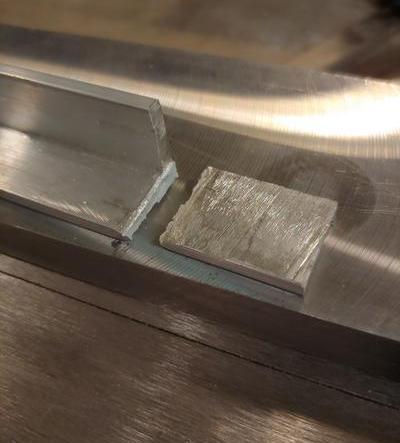

Some bent fine, some didn't. Didn't feel like doing cutting and measuring each piece only to gamble on the bend not turning into this:

Edit: In retrospect, preheating the bend would have probably produced the results wanted, but the next method will hopefully look better and make for stronger brackets.

Some bent fine, some didn't. Didn't feel like doing cutting and measuring each piece only to gamble on the bend not turning into this:

Edit: In retrospect, preheating the bend would have probably produced the results wanted, but the next method will hopefully look better and make for stronger brackets.