Hi

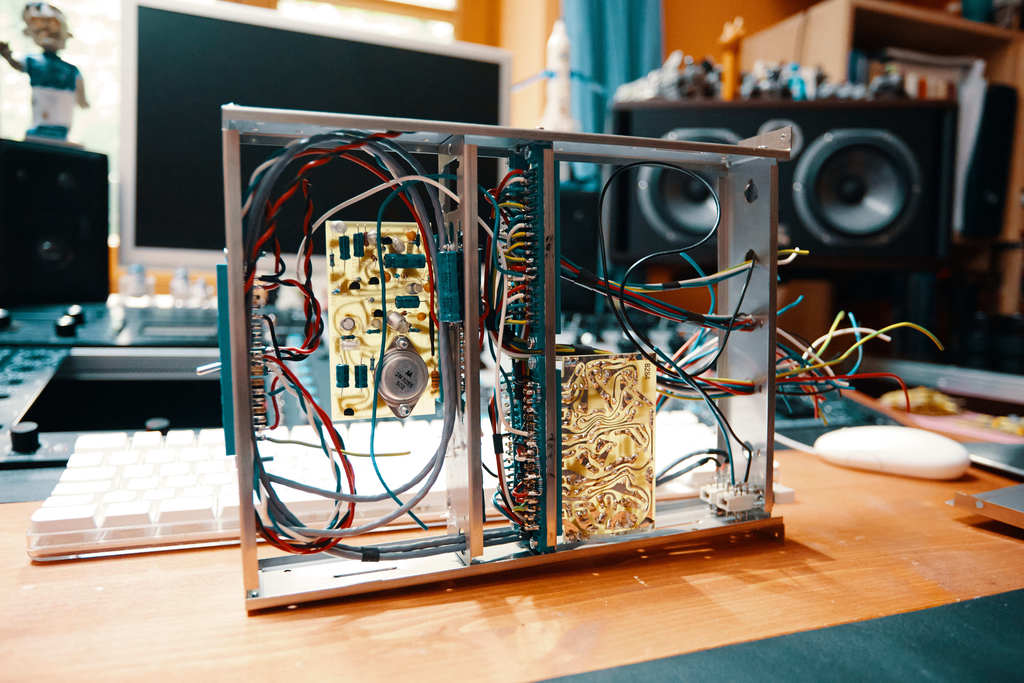

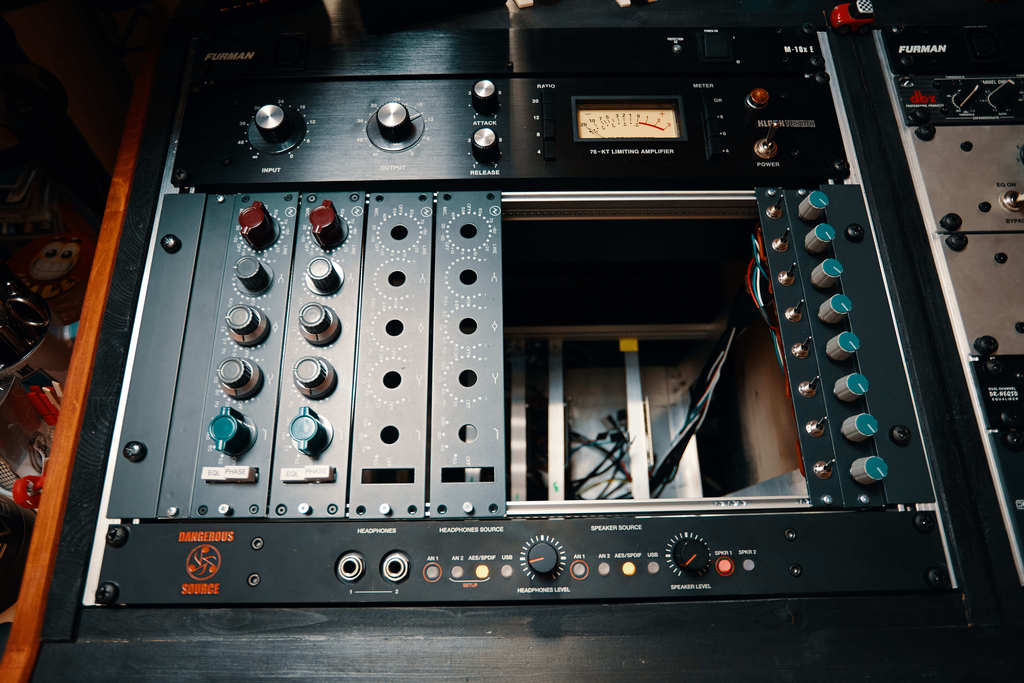

A while ago I bought 4 1073 cases from Beebird Audio and till now I didn't find time to finish them. I'm usually working as an FOH engineer and since there are no events in Austria due to Covid19, I decided to finish two of the modules.

Today I wanted to try the first channel, just with a BA283 in the module. I do get clean Audio in the first Amplifier Stage, the Gain Pot seems to work, but once it hits the second stage things do get weird.

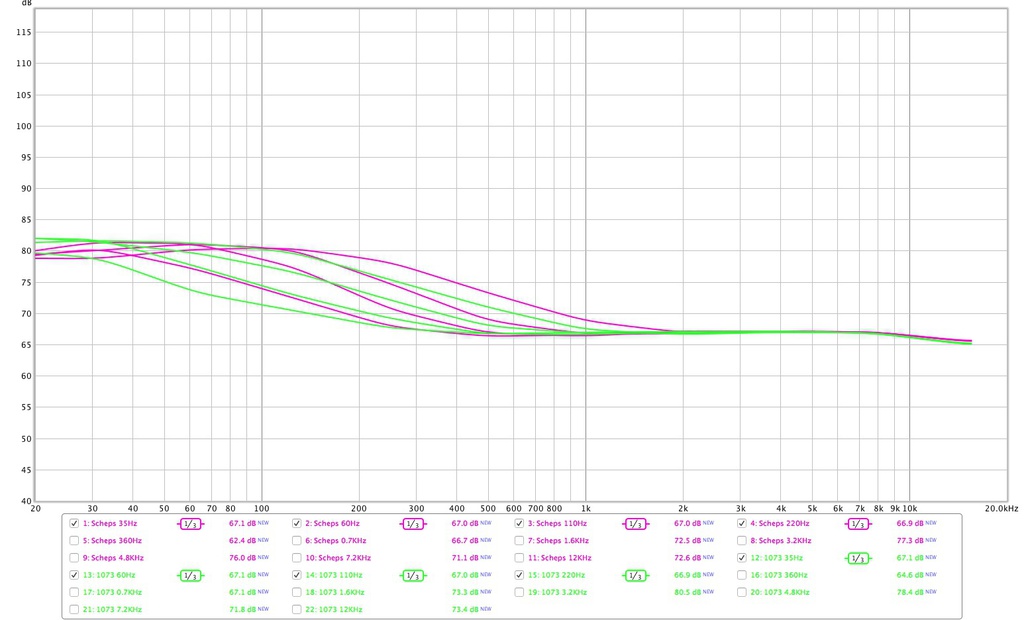

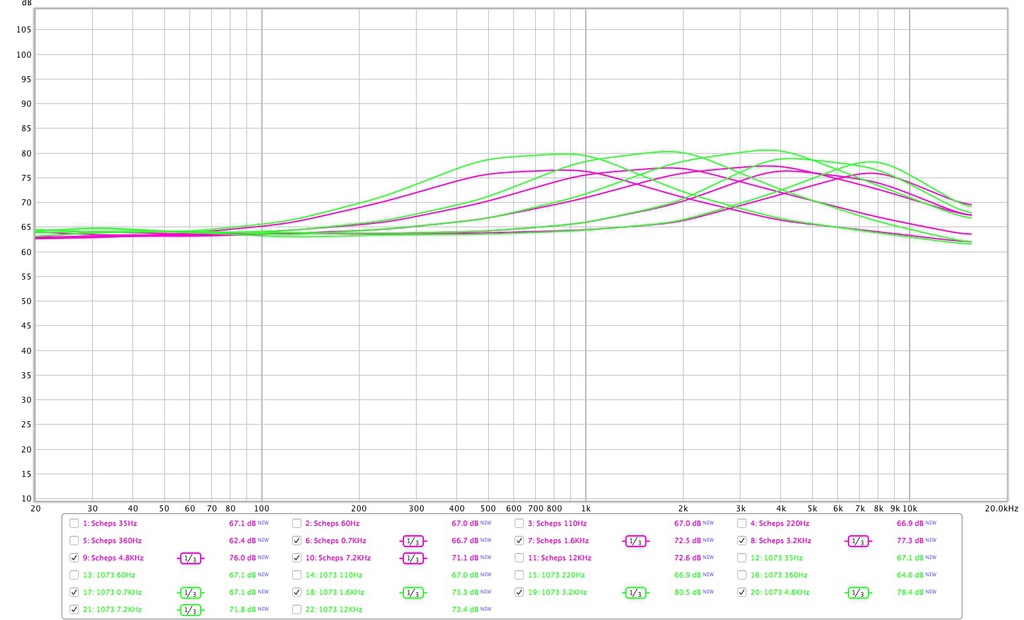

First off all Audio gets super distorted and R7 gets really hot. So I think I messed up my +24V wiring.

I followed the original Neve schematic.

A --> 0V

B --> VTB1148 Pin 1

J --> connected to A and V

L --> External Fader

M --> +24V via 12 Ohm Resistor, VTB1148 Pin 3

N --> +24V via 270 Ohm Resistor

P --> External Fader

S --> Connected to U via 18K Resistor

T --> Gain Switch

U --> Gain Switch

V --> Connected to J

What did I mess up? Does anyone have an idea?

Best wishes,

Johannes

A while ago I bought 4 1073 cases from Beebird Audio and till now I didn't find time to finish them. I'm usually working as an FOH engineer and since there are no events in Austria due to Covid19, I decided to finish two of the modules.

Today I wanted to try the first channel, just with a BA283 in the module. I do get clean Audio in the first Amplifier Stage, the Gain Pot seems to work, but once it hits the second stage things do get weird.

First off all Audio gets super distorted and R7 gets really hot. So I think I messed up my +24V wiring.

I followed the original Neve schematic.

A --> 0V

B --> VTB1148 Pin 1

J --> connected to A and V

L --> External Fader

M --> +24V via 12 Ohm Resistor, VTB1148 Pin 3

N --> +24V via 270 Ohm Resistor

P --> External Fader

S --> Connected to U via 18K Resistor

T --> Gain Switch

U --> Gain Switch

V --> Connected to J

What did I mess up? Does anyone have an idea?

Best wishes,

Johannes