MS Vienna

Well-known member

Hi everybody,

my Beyer mic had a problem: low output along with very strange sound.

So I took it apart and found quite a mess. The MC734 is a stage vocal mic (condenser). The capsule was just wrapped in foam and stuck into the grillecap. By now this foam wrapping has deteriorated pretty generously. So I carefully disassembled the capsule to check contamination. What I found was a surprisingly clean, yet broken SDC element.

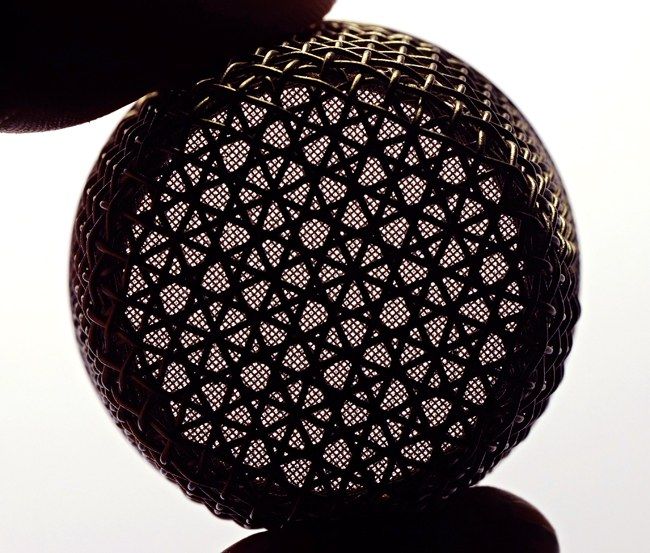

Beyer uses an interesting way to clamp diaphragms in place, similar to a drum head. On my capsule the ring that clamps down the diaphragm was broken probably due to material shrinkage.

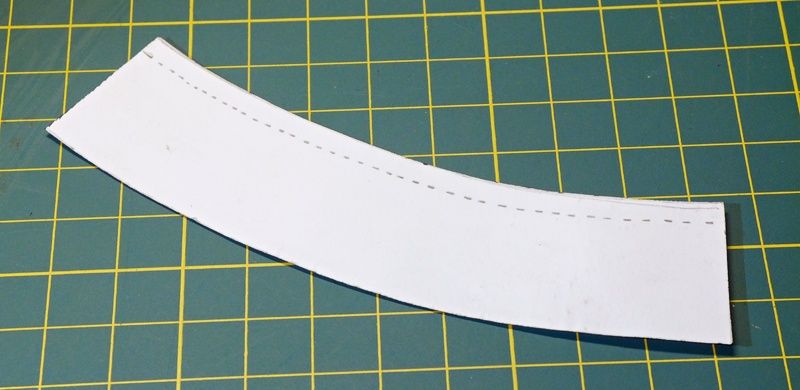

So I made a new ring. I used Polycarbonate since the material properties are pretty much perfect for this application: flexible, very hard to break, suited to precision machining and very heat resistant (important for the stabilisation process of the newly tensioned diaphragm).

I machined the ring´s inner diameter 0,01mm smaller than the brass rim it´s going to sit on. The diaphragm is 3µm thick (Polyester), so the ring is 16µm too small for a straight fit.

Polycarbonate is quite tough stuff so a stretch by this amount is enough to hold the delicate diaphragm securely in place.

Needless to say that I did need more than one try to get the diaphragm´s tension nice and even to a preliminary tension. After the stabilisation process the diaphragm is now settled to it´s final tension (and it´s gonna hold it for a long time). I´m sure I didn´t hit the original value but it´s in the ballpark and near enough (speaking from the resulting sound of the capsule).

BTW: The nice thing about this construction is thatI could re-use the original diaphragm - so this repair is quite close to a restoration

Looking through the clear new plastic ring you can see that this diaphragm originally must have been trimmed before tensioning (really interesting IMHO).

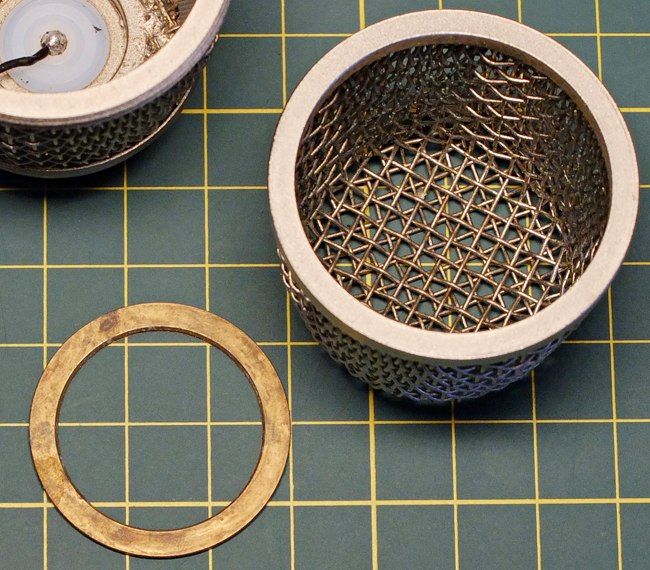

Here are all the components of the MC734 capsule

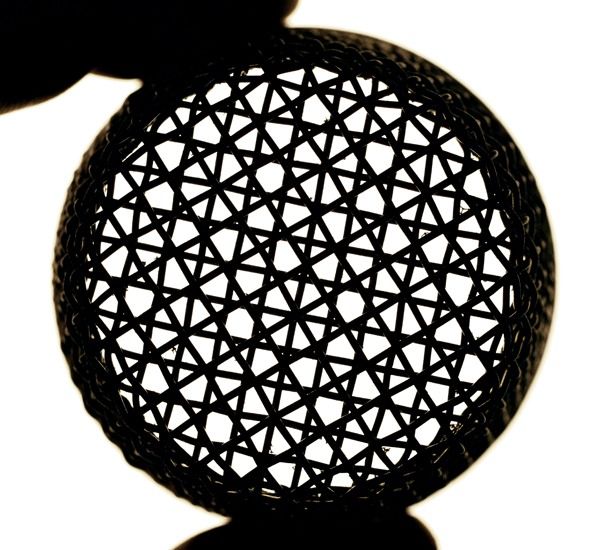

The next step ist to replace the deteriorated foam insert with a fine wiremesh layer and to make a capsule mount.

To be continued...

my Beyer mic had a problem: low output along with very strange sound.

So I took it apart and found quite a mess. The MC734 is a stage vocal mic (condenser). The capsule was just wrapped in foam and stuck into the grillecap. By now this foam wrapping has deteriorated pretty generously. So I carefully disassembled the capsule to check contamination. What I found was a surprisingly clean, yet broken SDC element.

Beyer uses an interesting way to clamp diaphragms in place, similar to a drum head. On my capsule the ring that clamps down the diaphragm was broken probably due to material shrinkage.

So I made a new ring. I used Polycarbonate since the material properties are pretty much perfect for this application: flexible, very hard to break, suited to precision machining and very heat resistant (important for the stabilisation process of the newly tensioned diaphragm).

I machined the ring´s inner diameter 0,01mm smaller than the brass rim it´s going to sit on. The diaphragm is 3µm thick (Polyester), so the ring is 16µm too small for a straight fit.

Polycarbonate is quite tough stuff so a stretch by this amount is enough to hold the delicate diaphragm securely in place.

Needless to say that I did need more than one try to get the diaphragm´s tension nice and even to a preliminary tension. After the stabilisation process the diaphragm is now settled to it´s final tension (and it´s gonna hold it for a long time). I´m sure I didn´t hit the original value but it´s in the ballpark and near enough (speaking from the resulting sound of the capsule).

BTW: The nice thing about this construction is thatI could re-use the original diaphragm - so this repair is quite close to a restoration

Looking through the clear new plastic ring you can see that this diaphragm originally must have been trimmed before tensioning (really interesting IMHO).

Here are all the components of the MC734 capsule

The next step ist to replace the deteriorated foam insert with a fine wiremesh layer and to make a capsule mount.

To be continued...

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)