skrasms

Well-known member

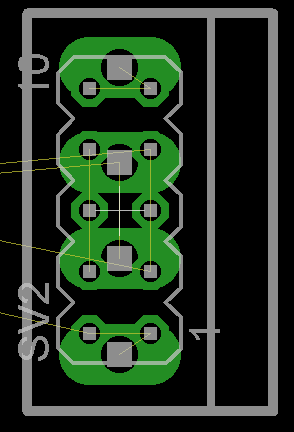

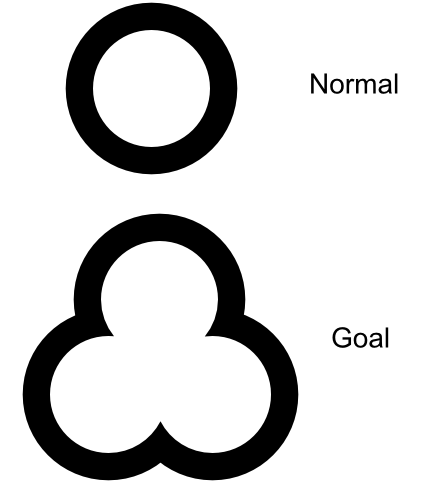

I ran into this issue today. The circuit can use either of two parts in a particular spot, and I want to include both without taking up a lot of extra board space. The problem is that there must be overlap of the pads and drill holes to make that possible. This picture shows what I'm going for:

Can that be altered so that a board house can do it? Eagle PCB won't let me come close to it.

Can that be altered so that a board house can do it? Eagle PCB won't let me come close to it.