Bo Deadly

Well-known member

My understanding of motor run capacitors is that there is an optimal size for a paticular motor running at a particular speed. The capacitor charges and discharges in pace with the orientation of the rotor. If the motor run capacitor is a little too large, the extra current will just give the motor a little more torque. If it's too small, torque will be less. The motor will simply run faster or slower depending on the size of the cap.

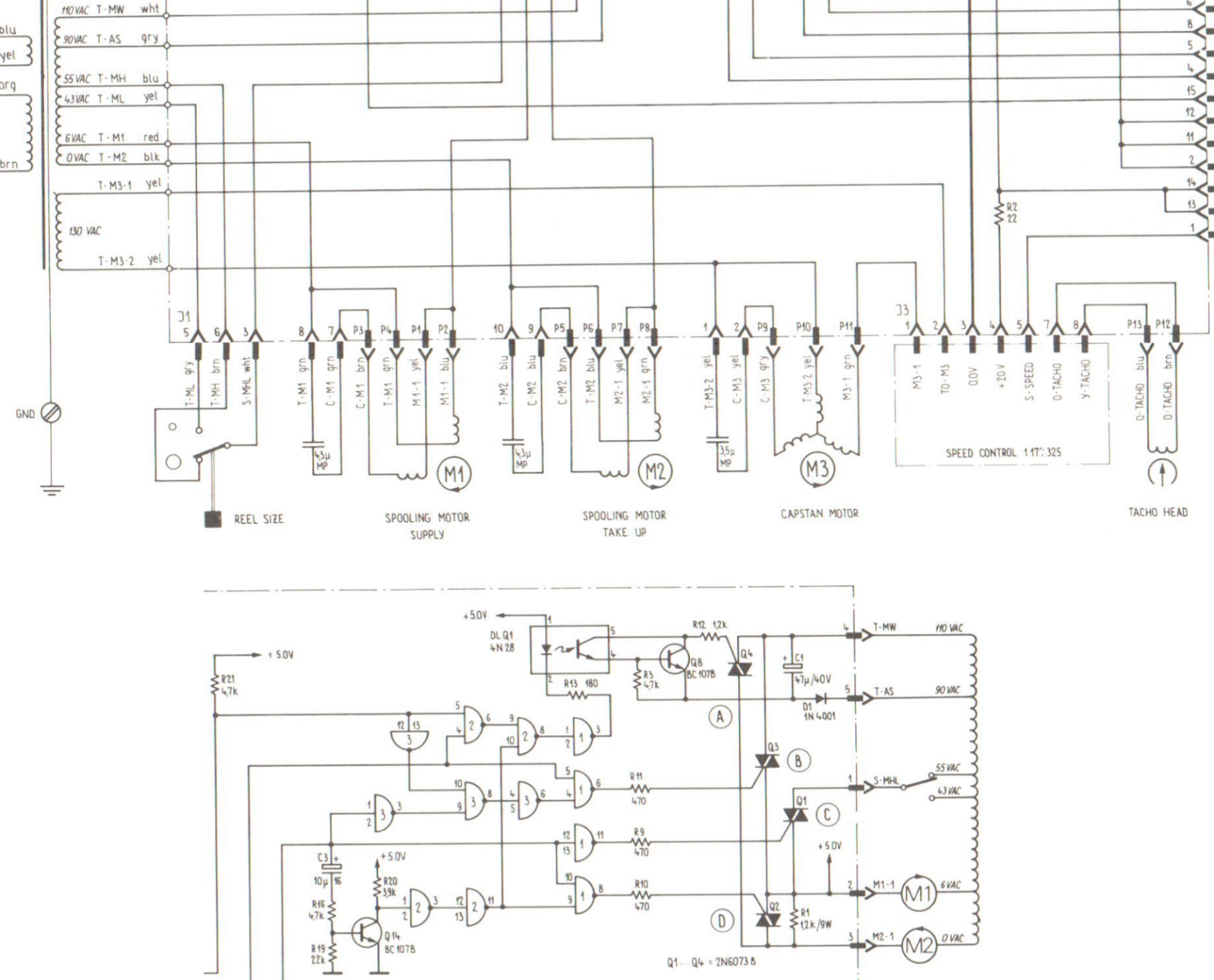

So then how does motor run capacitor size affect the performance of R2R motors? From looking at a ReVox B77 schematic, the capstan has a speed controller. So it will apply more or less AC modulation to increase or decrease current to, and thus speed of, the capstan motor. But the reel motors are not modulated. They're just on or off. The supply motor uses an different tap on the PT that is 6VAC less than the take up motor. Presumably this is what creates the tension between the two reels. No doubt other machines are probably more sophisticated about tension control but this seems to be how it works in the B77. The reel-size button just switches the common tap for the two reel motors.

Ultimately I think this means that if the motor run capacitor of the supply motor is too big, the capstan motor will not need to work as hard to pull tape from the supply reel and tension between the supply reel and capstan will be lower than normal. If the supply motor run capacitor is too small, the capstan will have to work harder to pull tape from the reel and increase tension.

So is this understanding correct? I just got a B77 so I'm just trying to understand how it actually works.

So then how does motor run capacitor size affect the performance of R2R motors? From looking at a ReVox B77 schematic, the capstan has a speed controller. So it will apply more or less AC modulation to increase or decrease current to, and thus speed of, the capstan motor. But the reel motors are not modulated. They're just on or off. The supply motor uses an different tap on the PT that is 6VAC less than the take up motor. Presumably this is what creates the tension between the two reels. No doubt other machines are probably more sophisticated about tension control but this seems to be how it works in the B77. The reel-size button just switches the common tap for the two reel motors.

Ultimately I think this means that if the motor run capacitor of the supply motor is too big, the capstan motor will not need to work as hard to pull tape from the supply reel and tension between the supply reel and capstan will be lower than normal. If the supply motor run capacitor is too small, the capstan will have to work harder to pull tape from the reel and increase tension.

So is this understanding correct? I just got a B77 so I'm just trying to understand how it actually works.

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)