Calibration - from Don Classics website http://www.thedonclassics.com/nv73manual.html

TESTS BEFORE TURN ON:

TRIM POT MUST BE TURNED COMPLETELY ANTI-CLOCKWISE

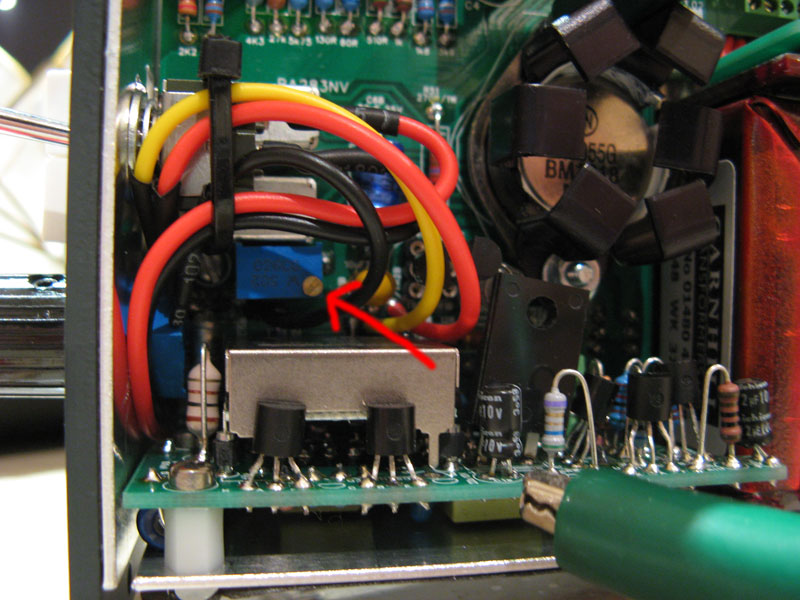

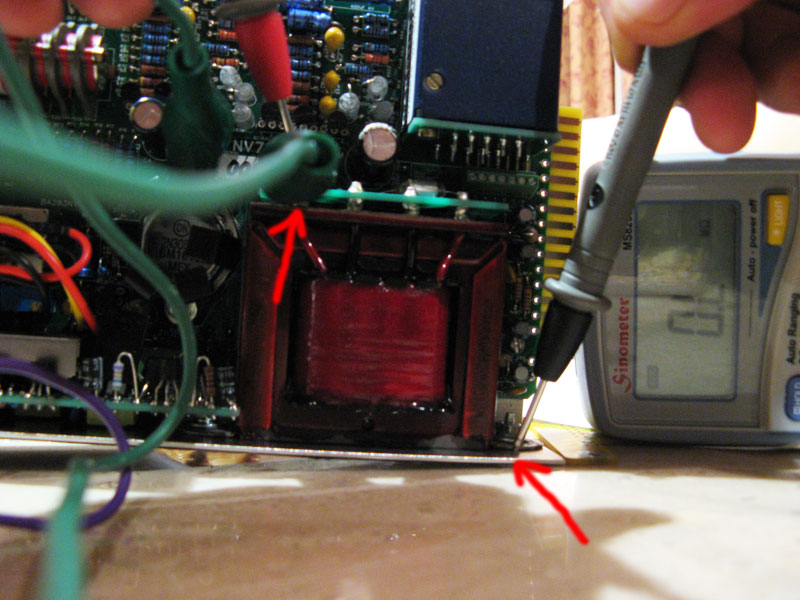

THE CASE OF THE 2N3055 MUST SHORT TO THE FIRST TERMINAL OF THE OUTPUT TRANSFORMER (PIN 1)

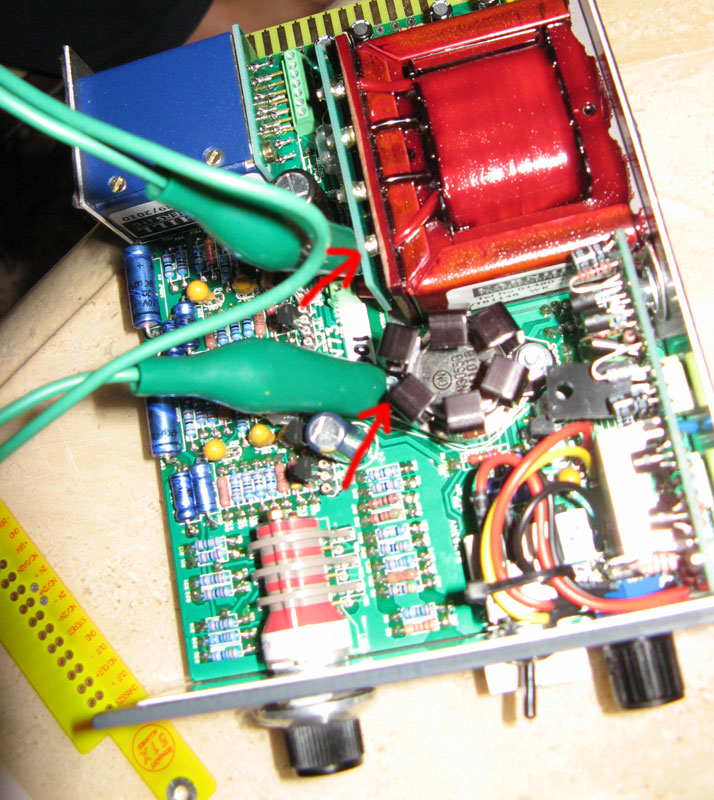

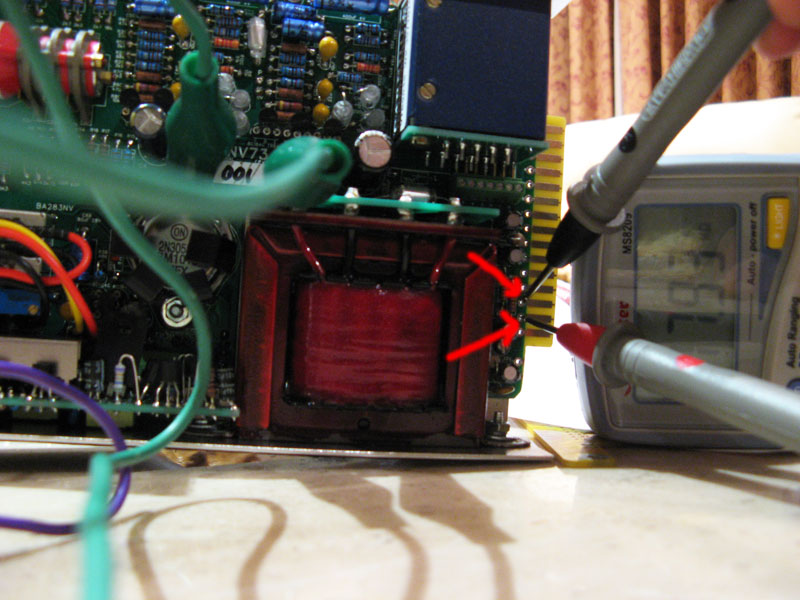

PIN 1 OF OUTPUT TRANSFORMER MUST NOT HAVE A RESISTANCE TO GROUND (SHOULD READ OFF THE SCALE OF YOUR MULTIMETER)

My multimeter reading is "O.L."

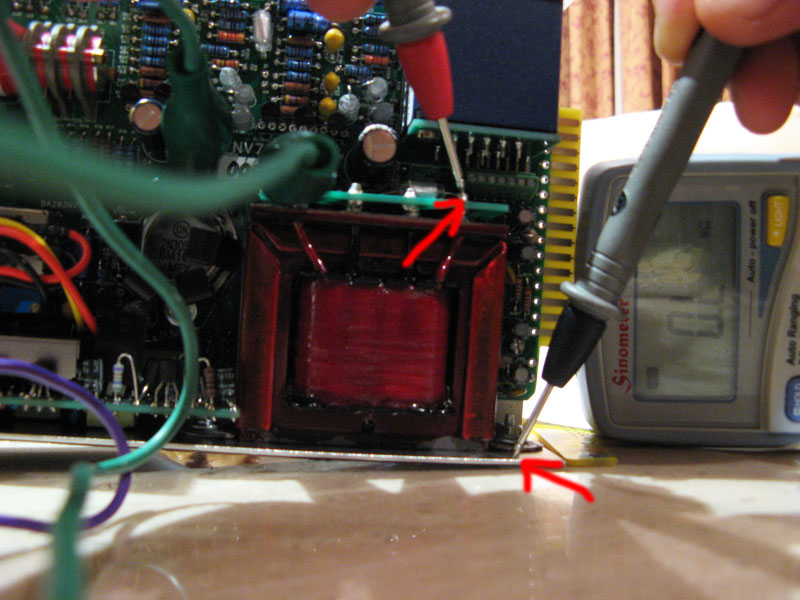

SAME AS ABOVE FOR PIN 3 OF OUTPUT TRANSFORMER

My multimeter reading is "O.L."

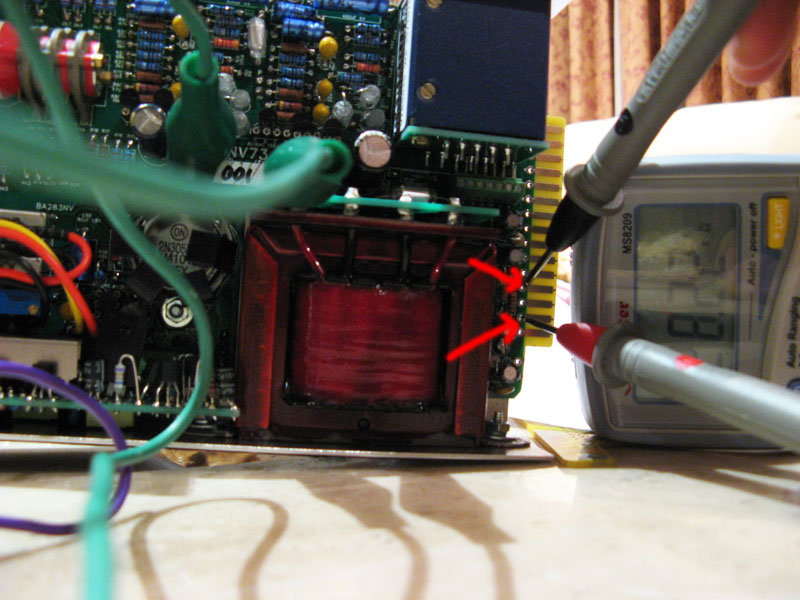

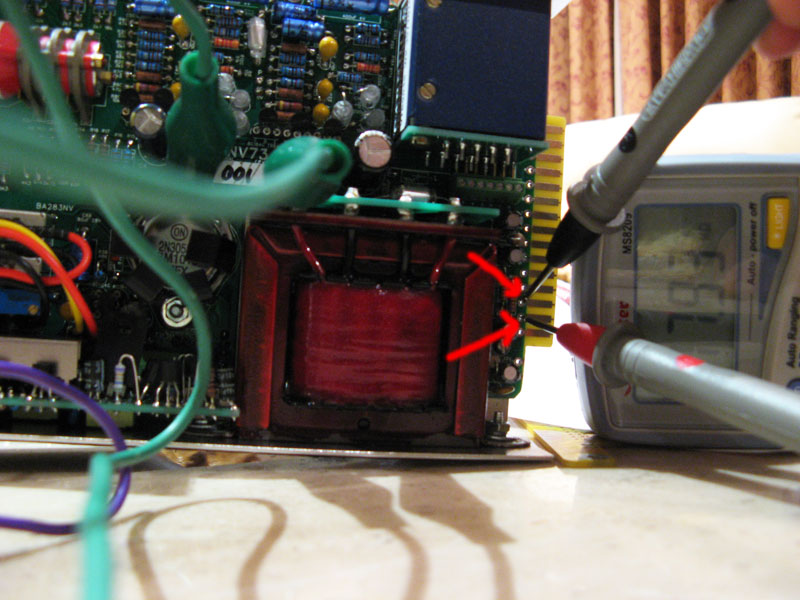

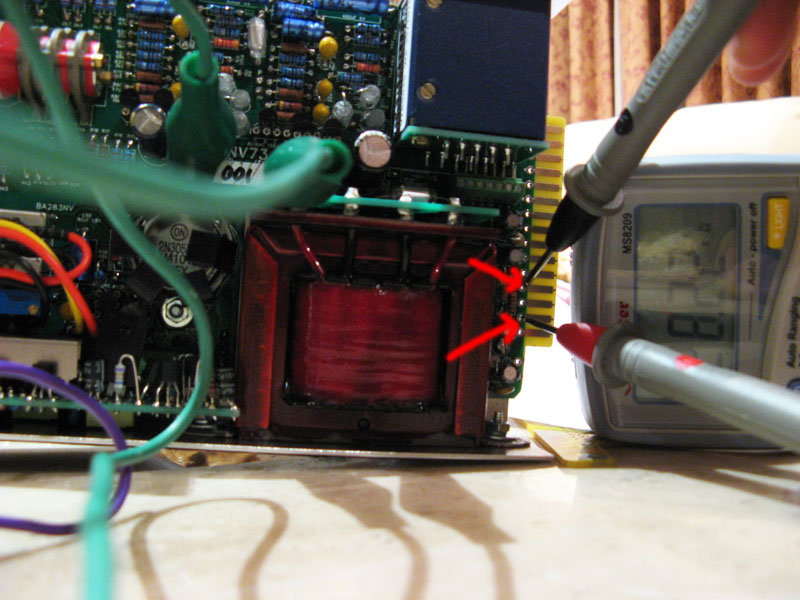

ON THE GOLD FINGERS, PIN 14 MUST HAVE A HIGH RESISTANCE (NOT SHORT) TO PIN 12 OR PIN 13

My multimeter reading is between "19-20MOhms"

TEST AFTER TURN ON

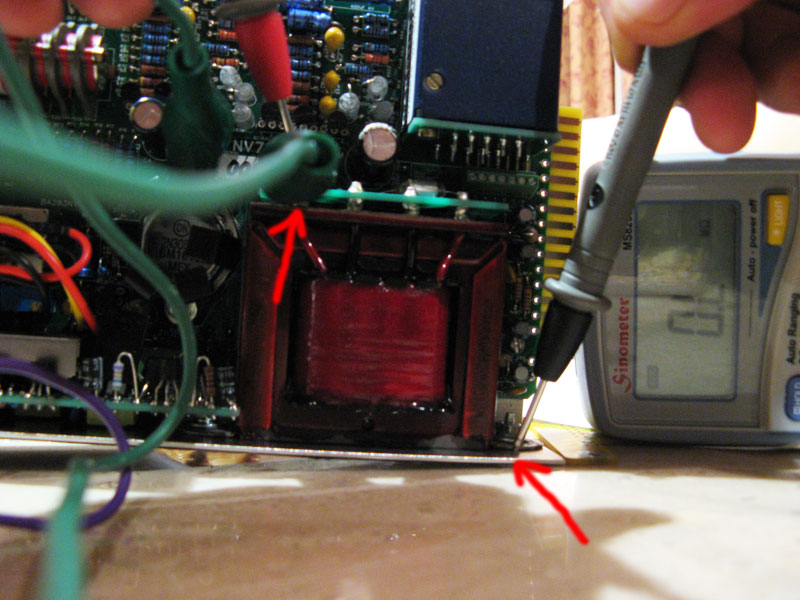

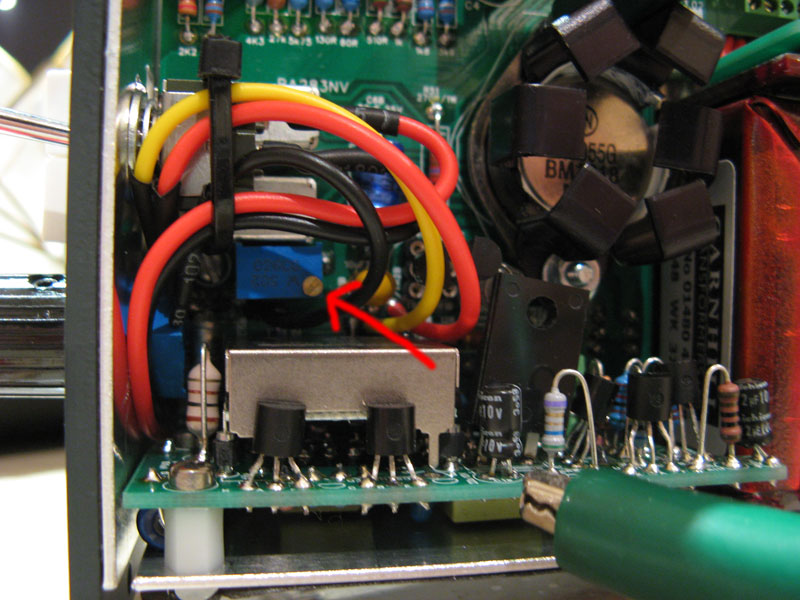

Make sure with one multimeter probe on the metal work and the other on the case of the 2N3055; test the voltage. MAKE SURE YOU GET A VOLTAGE OF NO LESS THAN 21V. IF YOU DO... TURN OFF IMMEDIATELY AND CHECK THAT YOU HAVE TURNED THE TRIM POT COMPLETELY COUNTERCLOCKWISE. (YOU SHOULD HEAR A CLICK EACH TIME YOU TURN WHEN YOU ARE AT COUNTER CLOCKWISE)

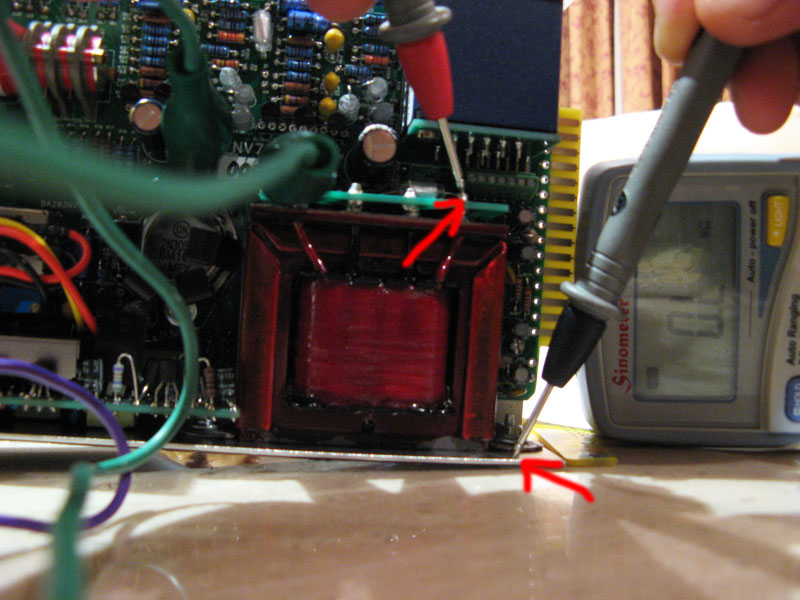

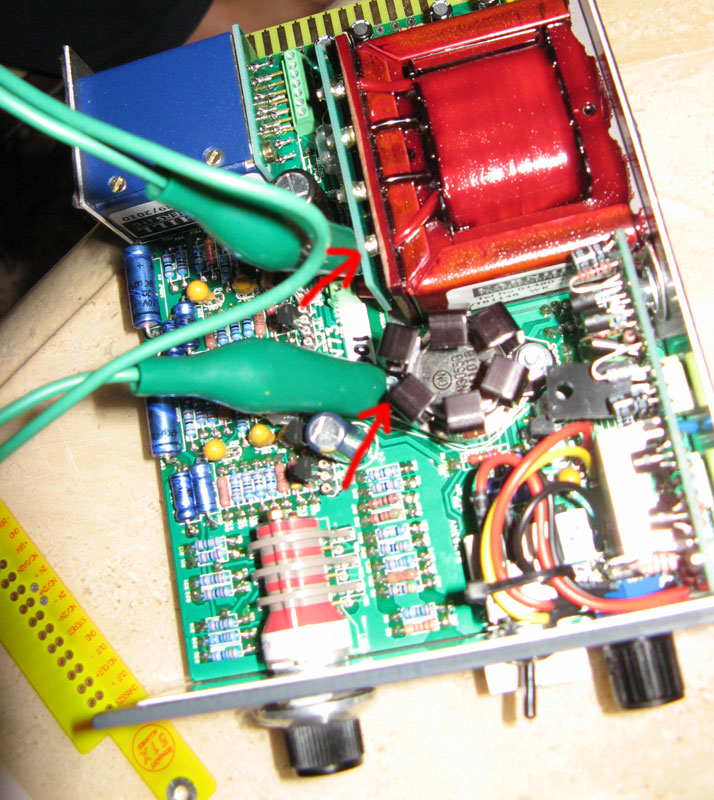

When fixed, you may turn the trimpot clockwise while measuring the voltage on the case of the 2N3055 still. When you reach 22V, it is set about right. An oscilloscope is needed for precise adjustment. (Adjust until both sides start to clip at the same time)

At this point, you can either test voltages at the legs of the BC184C transistors, or put some audio through it. When testing voltages on live circuits, you MUST be extremely careful not to short any pins together with the probe as the unit is turned on. If you are not confident doing this, you should plug some audio through it and only worry about testing further if your unit is not working correctly.

.............................................

I adjusted the trimpot till it read 22volts on my multimeter. When I connected an Oscilloscope and fed the NV a sine wave, and placed the two front panel knobs at maximum, I instantly got the clipped sine wave. It was a little blurry in some areas of the sine and occassionaly I would see a second clipped sine wave appear intermittently. That was the best result I was able to achieve with experimentation and so left it as it is. I measured my voltage when I placed both front panel knobs at maximum and I was getting 21.28 volts at probe at 2N3055 and ground at chassis.

TESTS BEFORE TURN ON:

TRIM POT MUST BE TURNED COMPLETELY ANTI-CLOCKWISE

THE CASE OF THE 2N3055 MUST SHORT TO THE FIRST TERMINAL OF THE OUTPUT TRANSFORMER (PIN 1)

PIN 1 OF OUTPUT TRANSFORMER MUST NOT HAVE A RESISTANCE TO GROUND (SHOULD READ OFF THE SCALE OF YOUR MULTIMETER)

My multimeter reading is "O.L."

SAME AS ABOVE FOR PIN 3 OF OUTPUT TRANSFORMER

My multimeter reading is "O.L."

ON THE GOLD FINGERS, PIN 14 MUST HAVE A HIGH RESISTANCE (NOT SHORT) TO PIN 12 OR PIN 13

My multimeter reading is between "19-20MOhms"

TEST AFTER TURN ON

Make sure with one multimeter probe on the metal work and the other on the case of the 2N3055; test the voltage. MAKE SURE YOU GET A VOLTAGE OF NO LESS THAN 21V. IF YOU DO... TURN OFF IMMEDIATELY AND CHECK THAT YOU HAVE TURNED THE TRIM POT COMPLETELY COUNTERCLOCKWISE. (YOU SHOULD HEAR A CLICK EACH TIME YOU TURN WHEN YOU ARE AT COUNTER CLOCKWISE)

When fixed, you may turn the trimpot clockwise while measuring the voltage on the case of the 2N3055 still. When you reach 22V, it is set about right. An oscilloscope is needed for precise adjustment. (Adjust until both sides start to clip at the same time)

At this point, you can either test voltages at the legs of the BC184C transistors, or put some audio through it. When testing voltages on live circuits, you MUST be extremely careful not to short any pins together with the probe as the unit is turned on. If you are not confident doing this, you should plug some audio through it and only worry about testing further if your unit is not working correctly.

.............................................

I adjusted the trimpot till it read 22volts on my multimeter. When I connected an Oscilloscope and fed the NV a sine wave, and placed the two front panel knobs at maximum, I instantly got the clipped sine wave. It was a little blurry in some areas of the sine and occassionaly I would see a second clipped sine wave appear intermittently. That was the best result I was able to achieve with experimentation and so left it as it is. I measured my voltage when I placed both front panel knobs at maximum and I was getting 21.28 volts at probe at 2N3055 and ground at chassis.