Aj

Well-known member

Just dug this handsome thing out of storage. Been meaning to ask this for ages, so...

Two years ago - while on vacation with the kids (west coast of Michigan), I found an interesting piece at a roadside antique mall. It's a 3U Valley People rack with 8 mic pres.

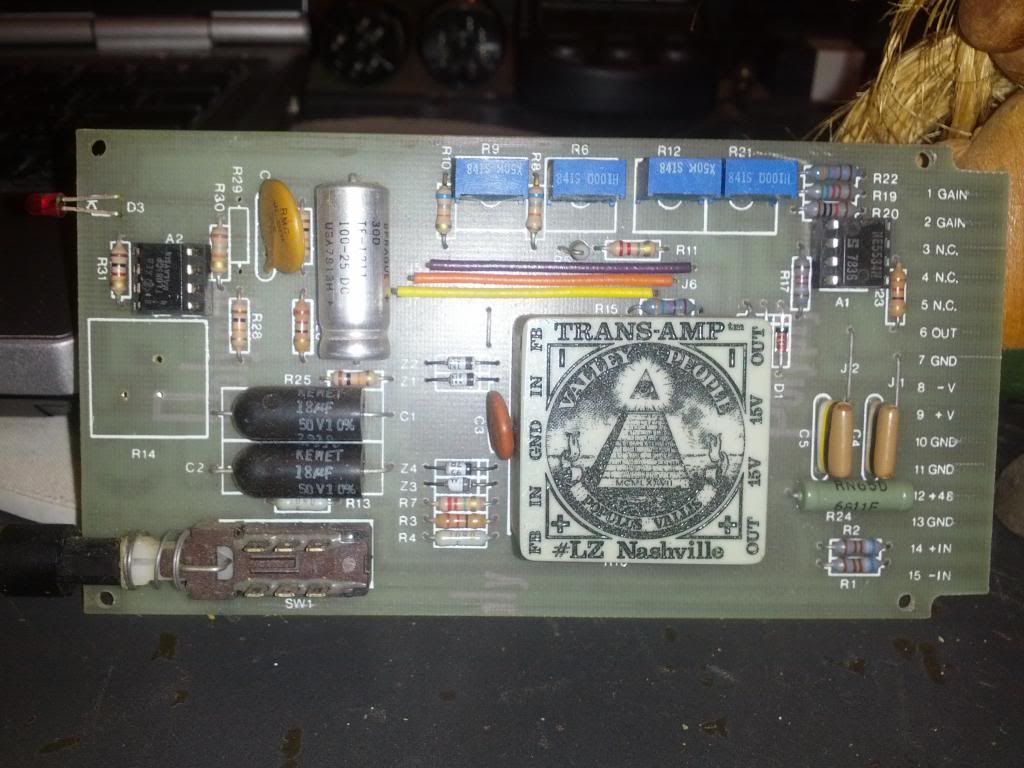

Of all things to find, right? It looks to be 1970s-era. The pres say "Valley People Trans-Amp #LZ Nashville". Each are big, green, square plastic modules - on green PCB cards, with machine traces and hand-soldered resistors, caps, etc. Cool looking things.

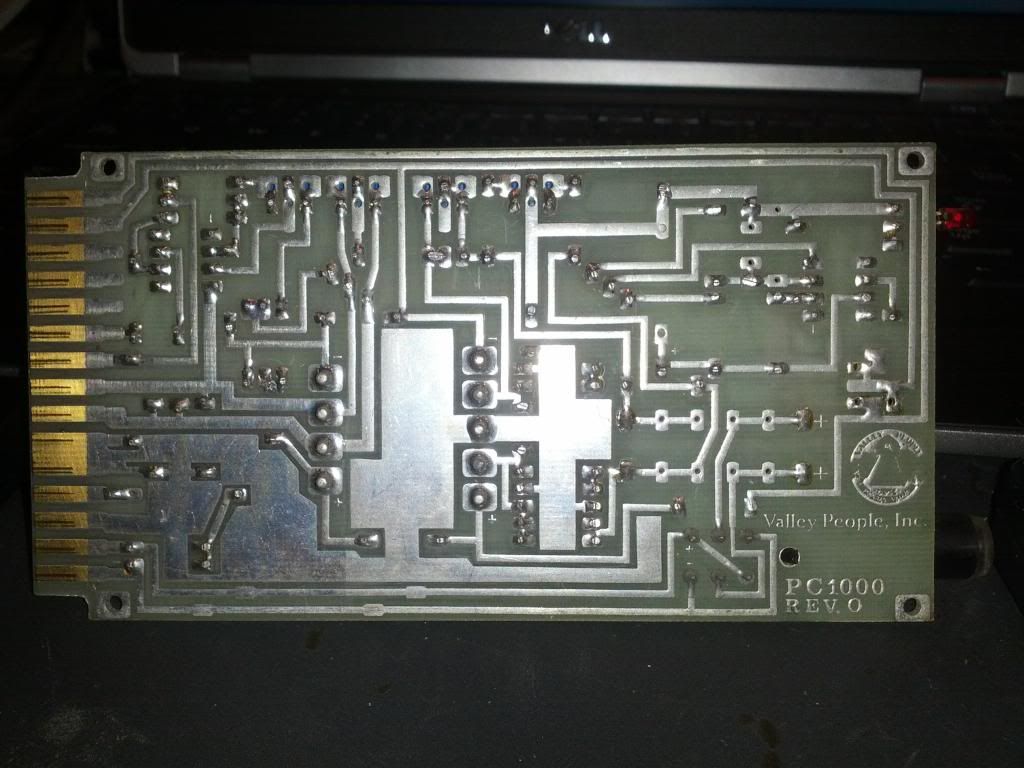

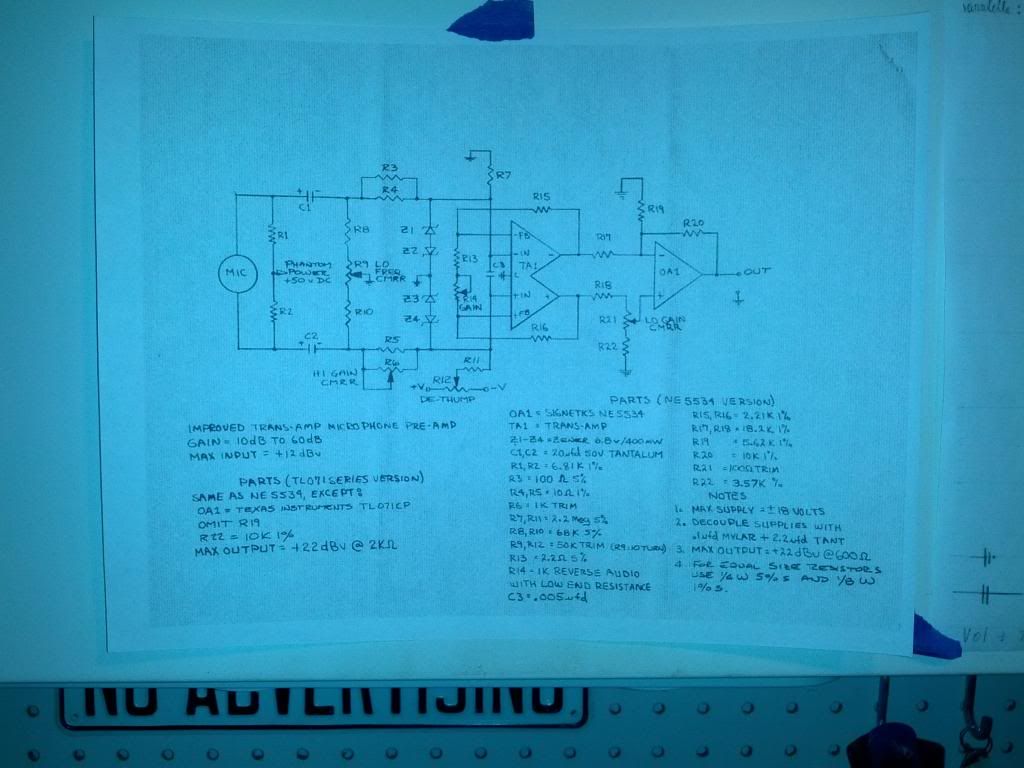

I'd like to recap these and learn their lineage. Research's uncovered little. Back of the card says "PC 1000 Rev 0" - though I wonder if these are early MP-1000 pres (Paul Buff). Says "FB IN GND IN FB" on the green block (some sort of feedback circuit?). There are a couple chips (op amps?), aside from what's under the big green block (which I assume hides some sort of transistor/chip circuit?). One chip says, "TLO81CP" (looks to be TI) and the other says, "NE55433N S 7836". These easily pop in/out, by hand.

Anyone know anything about these? I did read in one old post that they were used in MCI's larger boards around '77-78. Oh, and Frank Zappa used them - supposedly. And last, not least - does anyone have a schematic? I found schems linked in old posts, but all have gone dry.

Five of these seemed to work last time I checked; others seemed to need service. I'm not an electronics expert, but I get by with an iron and a meter. Any info on getting this back in action much appreciated!

Aj in Michigan

Two years ago - while on vacation with the kids (west coast of Michigan), I found an interesting piece at a roadside antique mall. It's a 3U Valley People rack with 8 mic pres.

Of all things to find, right? It looks to be 1970s-era. The pres say "Valley People Trans-Amp #LZ Nashville". Each are big, green, square plastic modules - on green PCB cards, with machine traces and hand-soldered resistors, caps, etc. Cool looking things.

I'd like to recap these and learn their lineage. Research's uncovered little. Back of the card says "PC 1000 Rev 0" - though I wonder if these are early MP-1000 pres (Paul Buff). Says "FB IN GND IN FB" on the green block (some sort of feedback circuit?). There are a couple chips (op amps?), aside from what's under the big green block (which I assume hides some sort of transistor/chip circuit?). One chip says, "TLO81CP" (looks to be TI) and the other says, "NE55433N S 7836". These easily pop in/out, by hand.

Anyone know anything about these? I did read in one old post that they were used in MCI's larger boards around '77-78. Oh, and Frank Zappa used them - supposedly. And last, not least - does anyone have a schematic? I found schems linked in old posts, but all have gone dry.

Five of these seemed to work last time I checked; others seemed to need service. I'm not an electronics expert, but I get by with an iron and a meter. Any info on getting this back in action much appreciated!

Aj in Michigan