OK. . . now that I'm oriented and have a map for the internal wiring, I'm ready to push and finish out the point-to-point version of the PSU.

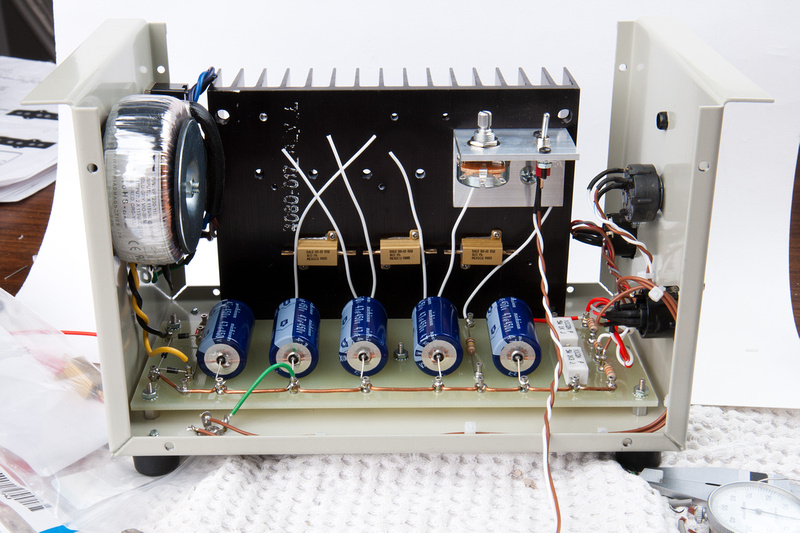

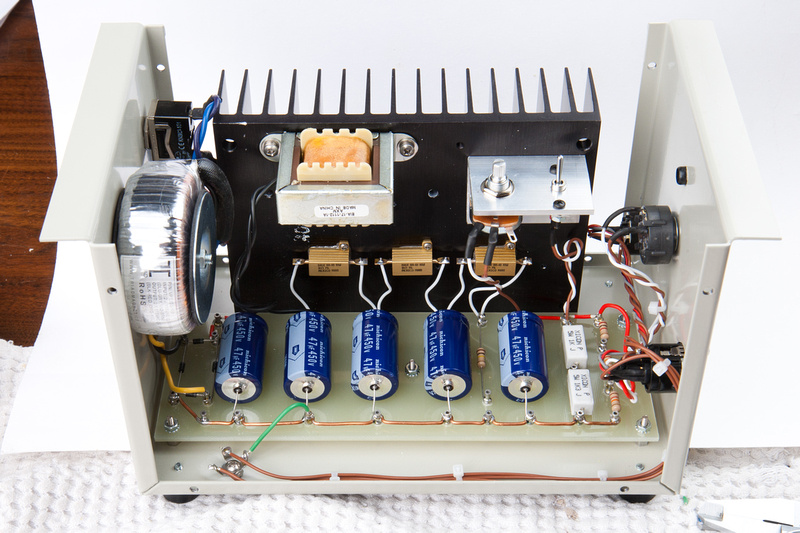

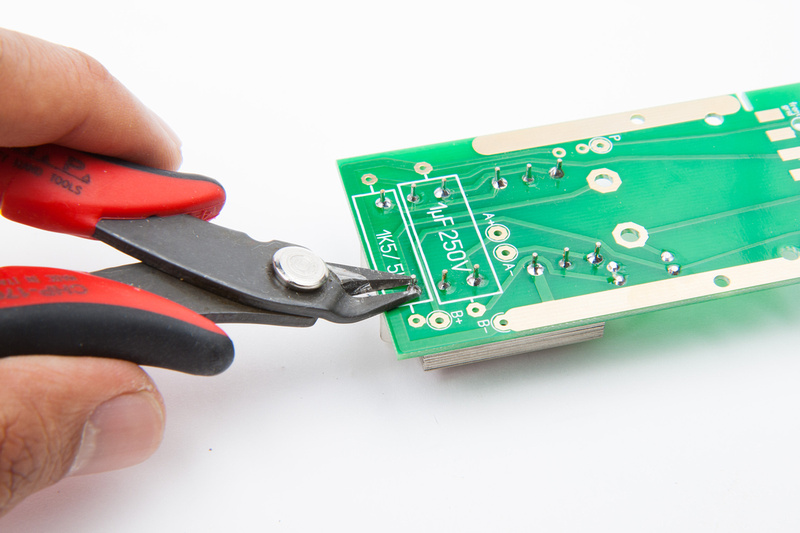

First, some logistical enclosure items. I remove the heat sink assembly, the turret board, toroid, and the IEC.

I prep one of the IEC screw holes for my safety ground. This time, I got smart and used a wire wheel attachment on my rotary tool. Works way faster than sandpaper.

\

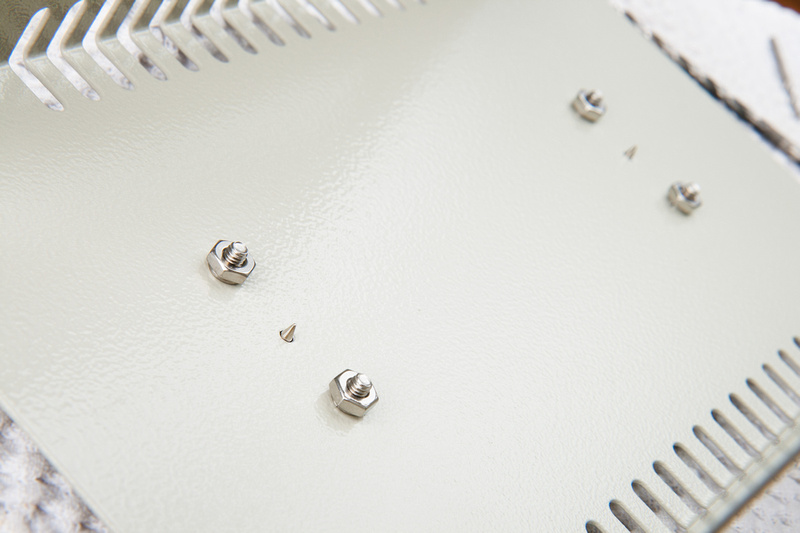

Everyone seems to complain about the thickness of the Hammond enclosure's steel. . . I haven't found it to be too problematic, but since we have thicker steel, I figured it would be a nice touch to tap the holes to mount the cover instead of using the included self-tapping screws. I tap for 8-32.

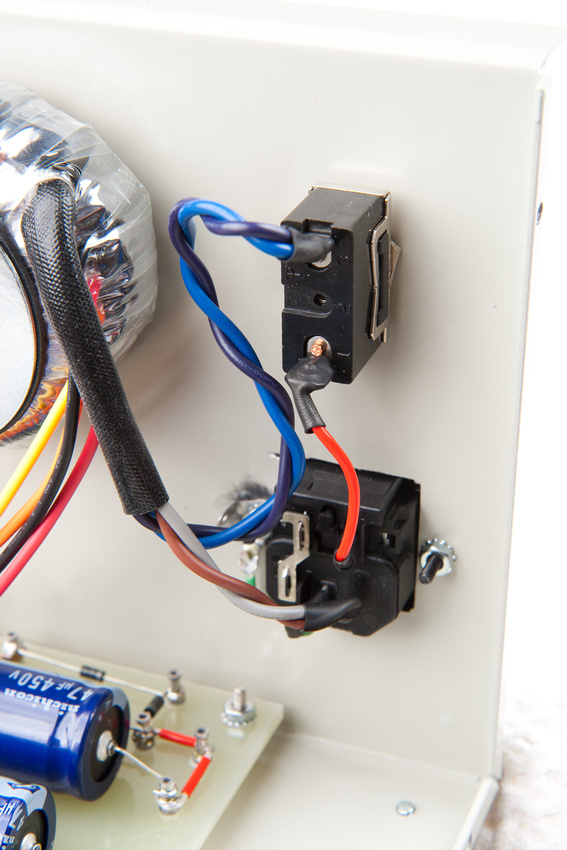

IEC mounted with a solder tab for my safety ground.

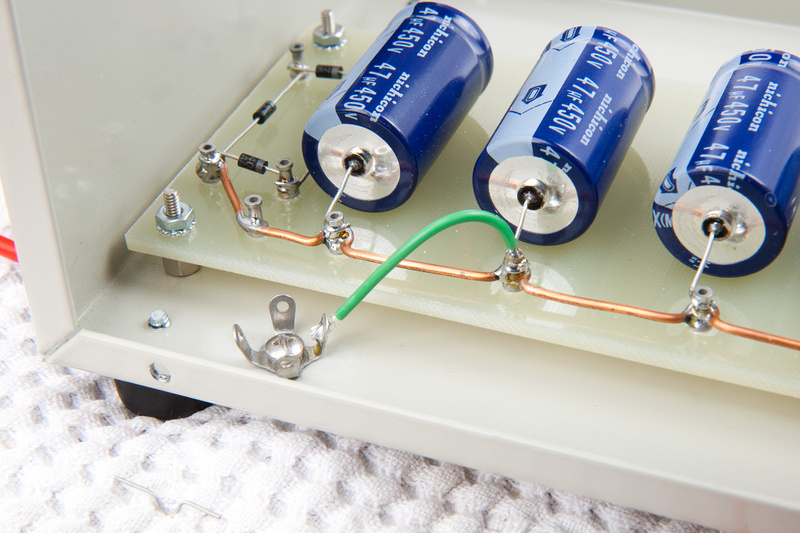

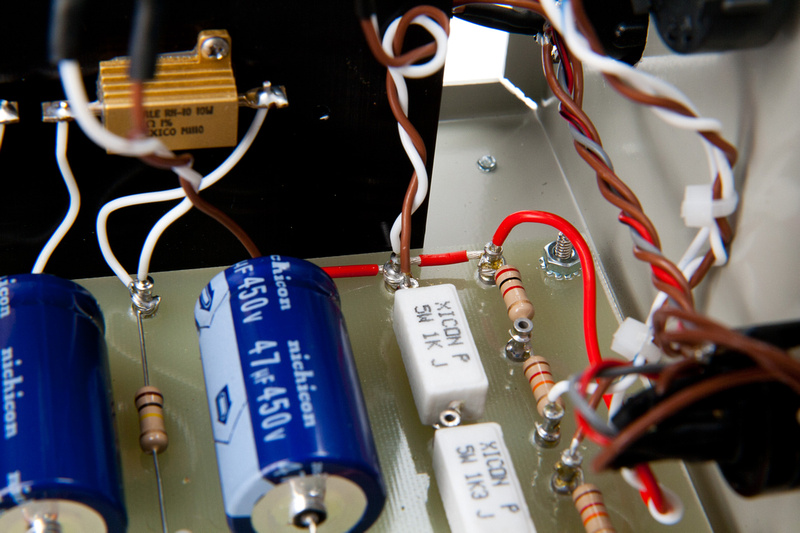

Given the number of wires I anticipate bringing to the star ground point, I add an additional solder tab there as well.

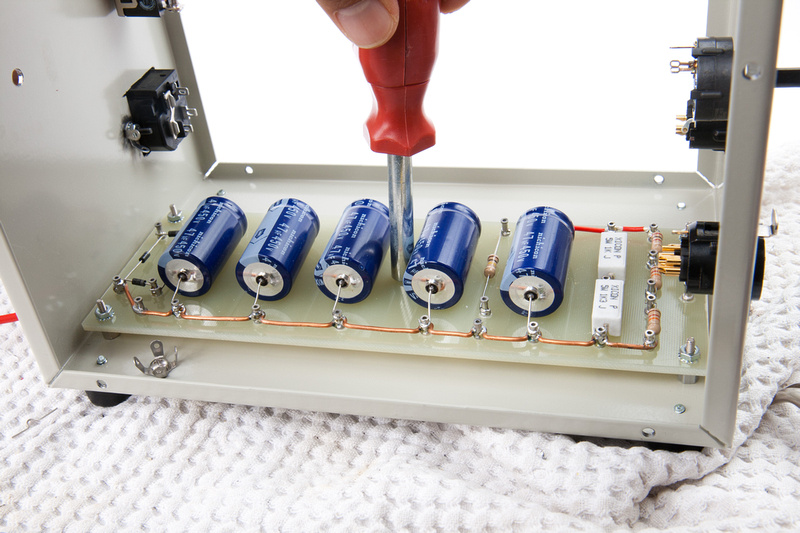

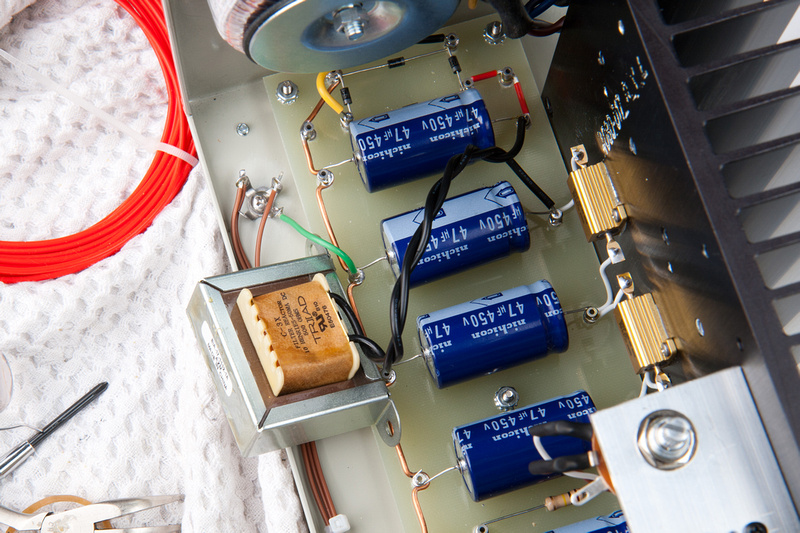

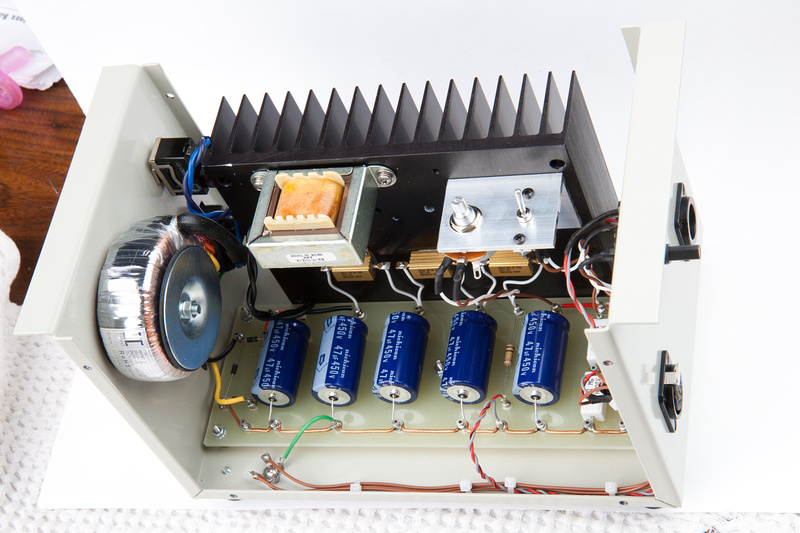

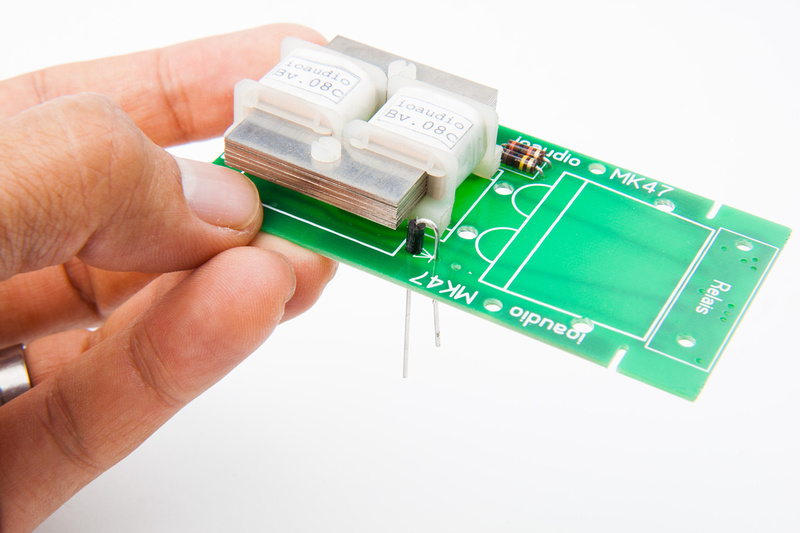

Next, I re-install the turret board hopefully for the final time.

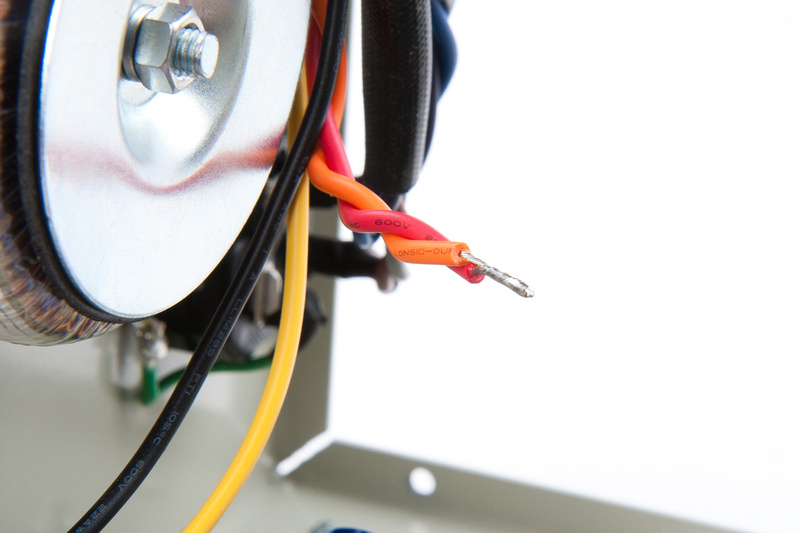

and begin my mains wiring. I am using silver teflon wire throughout. I have purchased various colors and gauges here and there on Ebay and have built up a small supply.

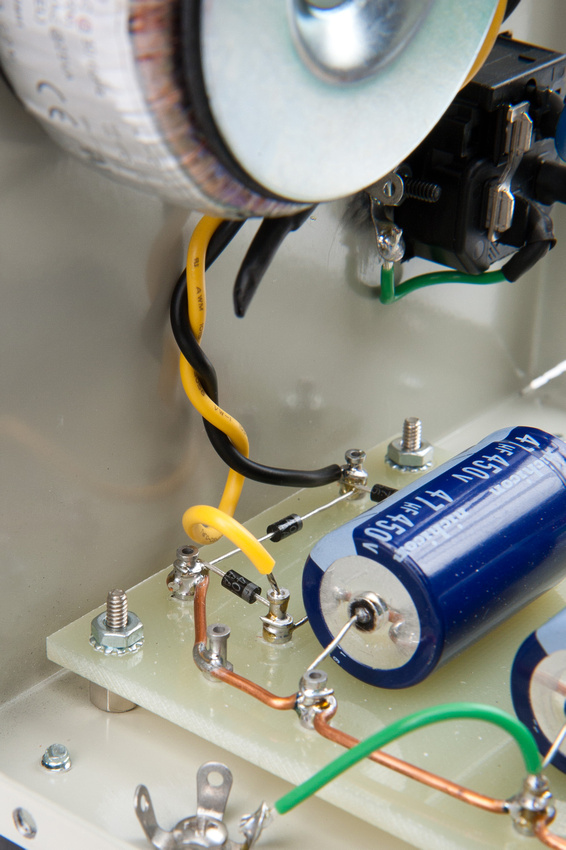

turret board connects to star ground.

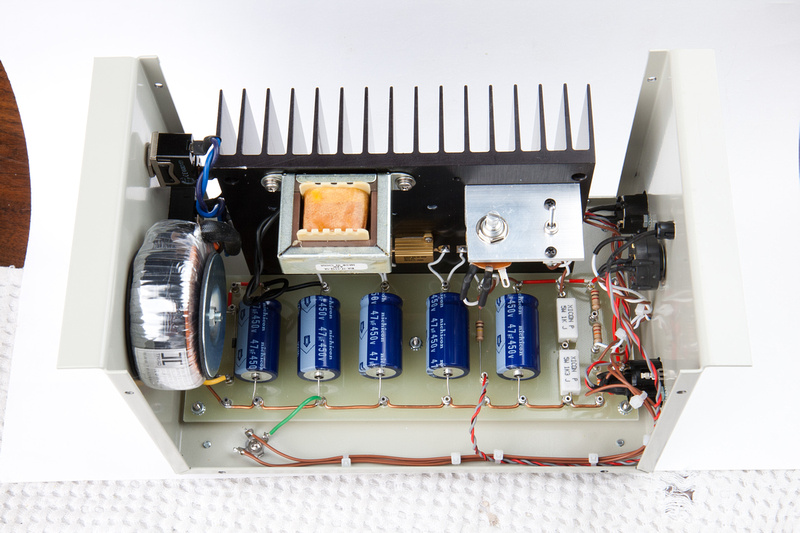

Here I re-install the toroid and wire in the primaries. For this Triad toroid in the US (110V), I wire the primaries in parallel.

The secondaries will go in series, so these two wires are spliced together and securely covered with some shrink tubing.

And the secondaries feed into the turret board here.

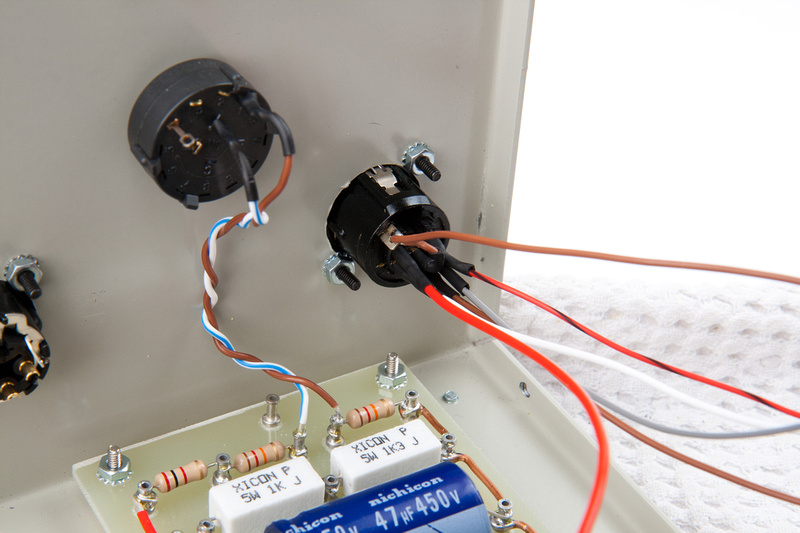

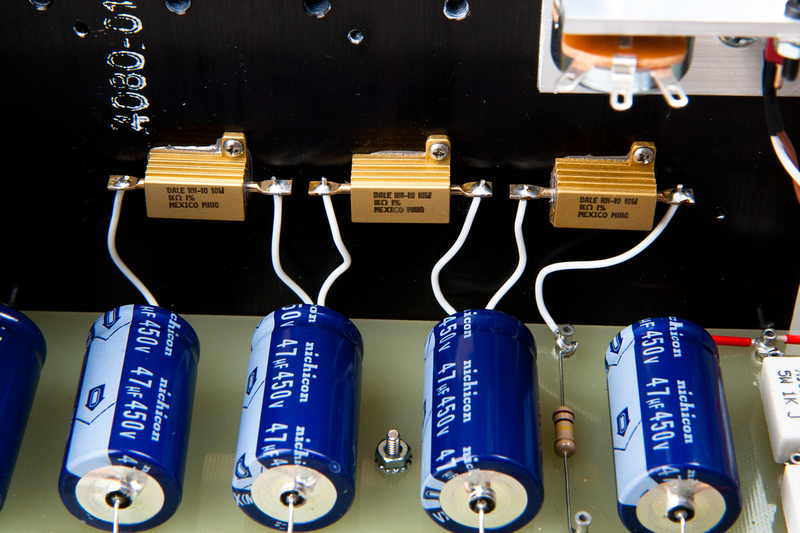

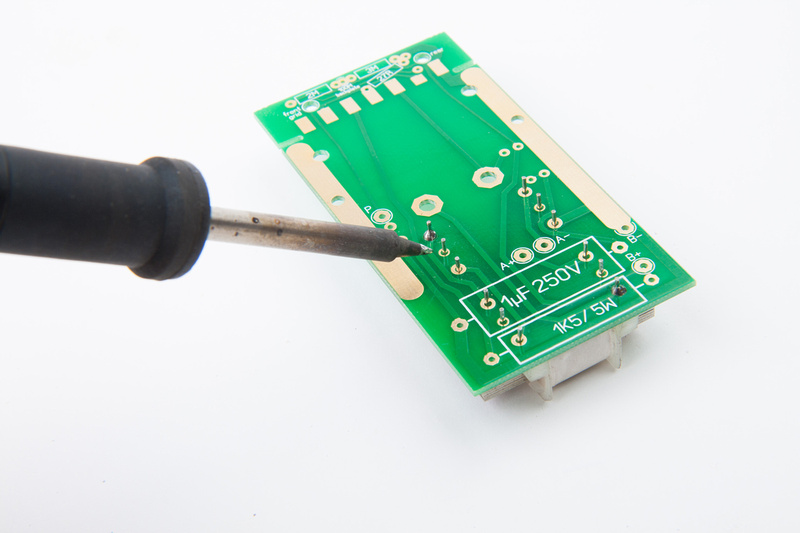

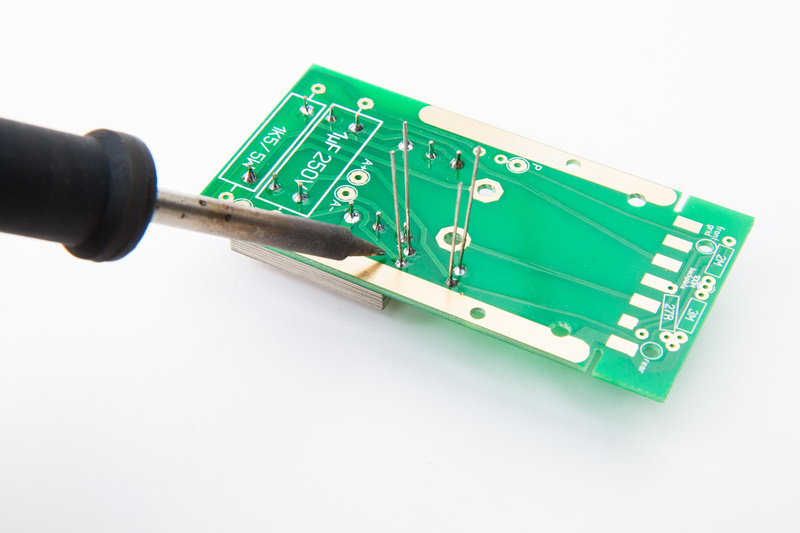

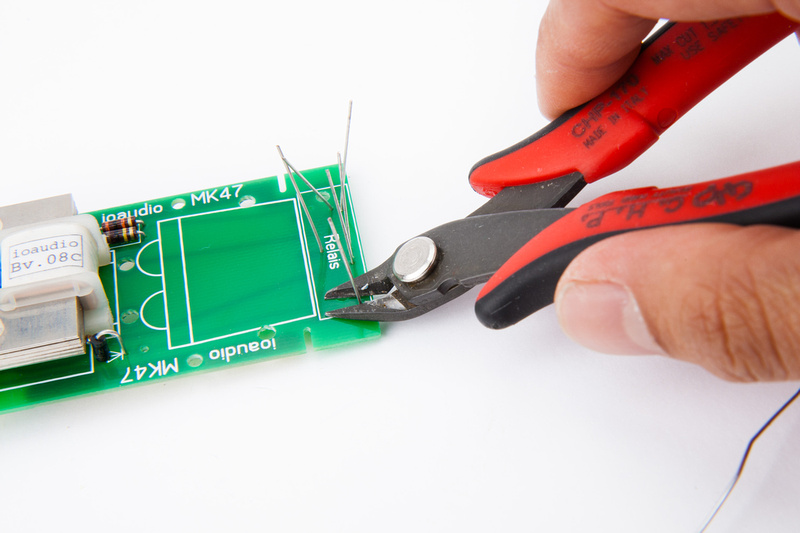

Since it will be difficult to solder along the back edge of the turret board once the heat sink is installed, I pre-install some "pigtails" to the back side turrets. These will connect to the chassis-mount-type resistors that are already installed on the heat sink assembly.

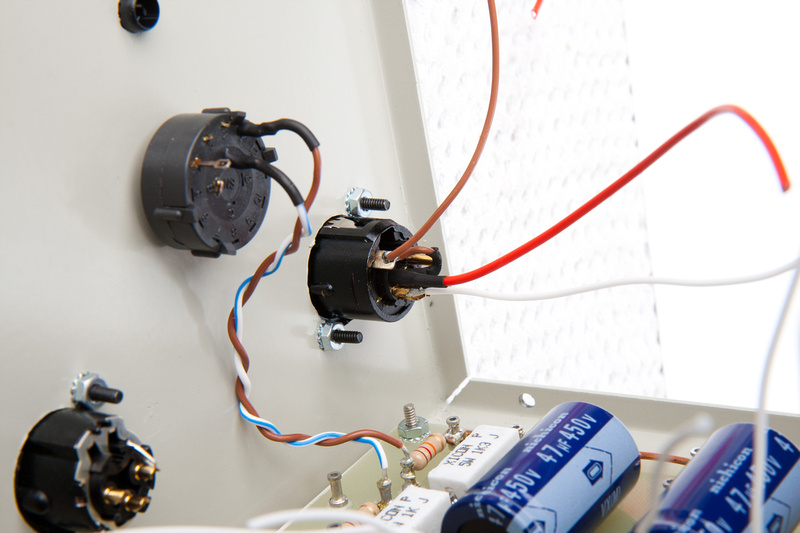

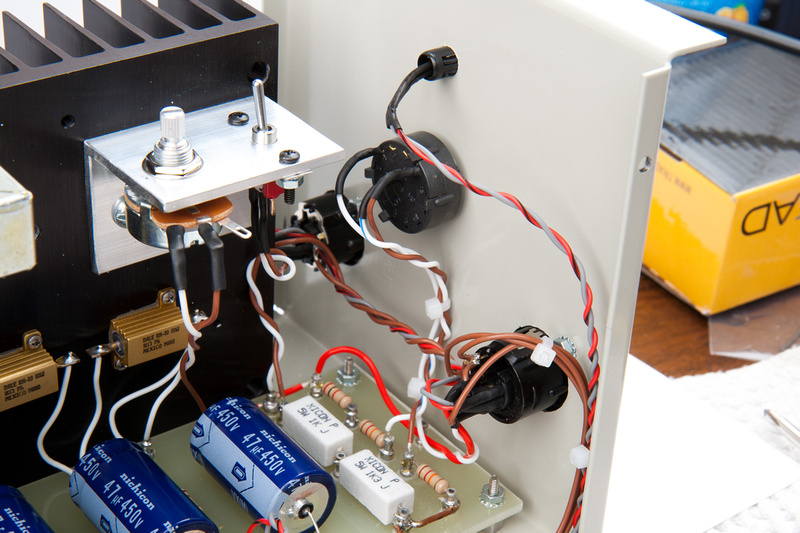

The Cardioid mode wires are installed on the pattern select switch and I begin wiring the 7 pin XLR. Here chassis ground, +105V and +48V pattern wires are being installed.

Next, audio 0V, audio +, and audio - go into the 7 pin XLR.

+105V and pattern are hooked into the turret board and pattern select switch.

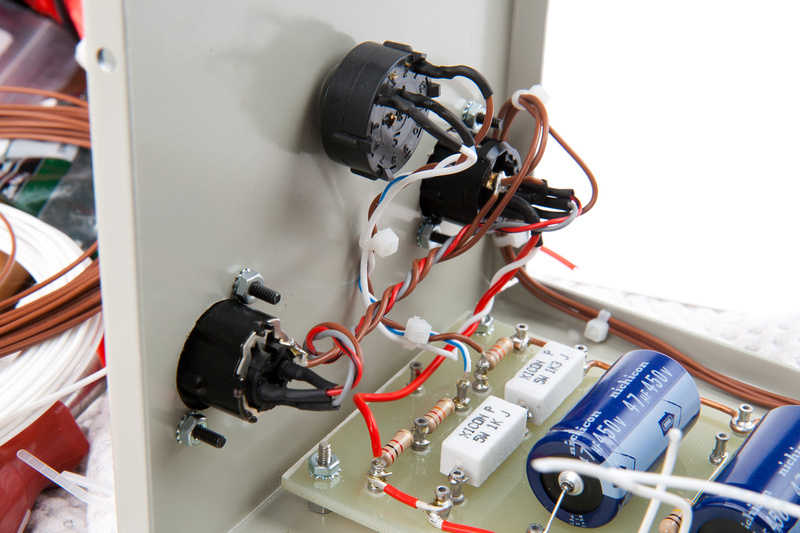

And the output 3 pin XLR is wired in.

in my mind, this was going to come out a lot neater, but I guess it's not a total embarrassment. It should be quite solid.

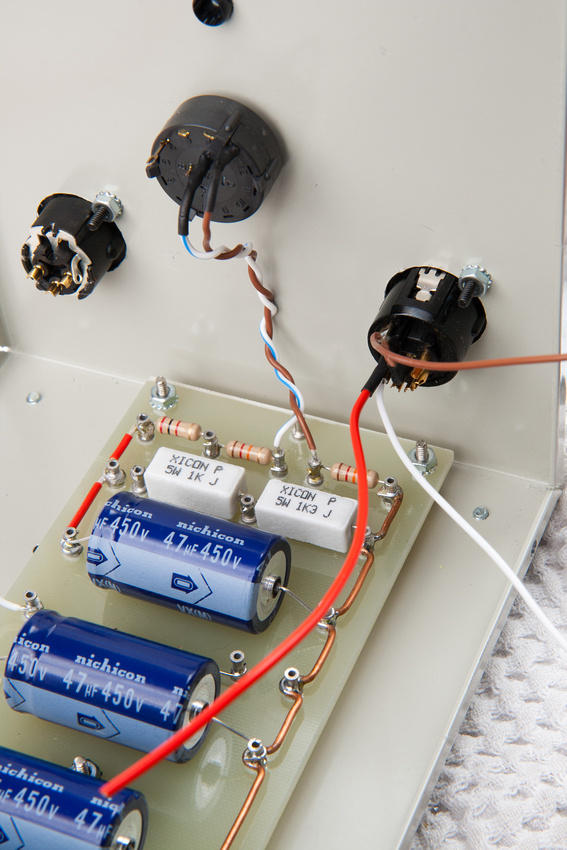

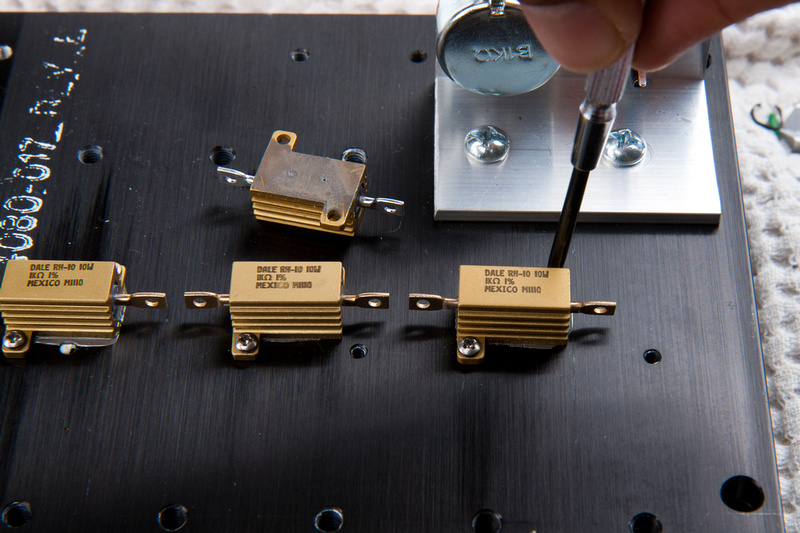

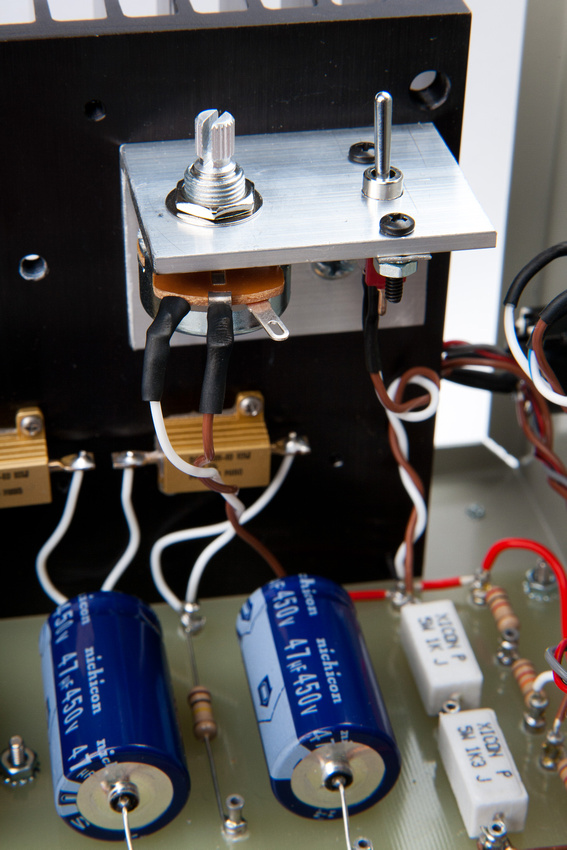

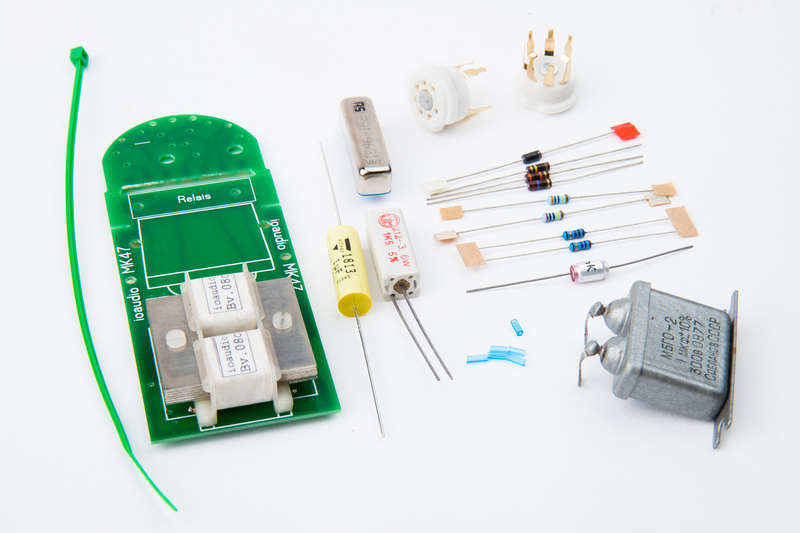

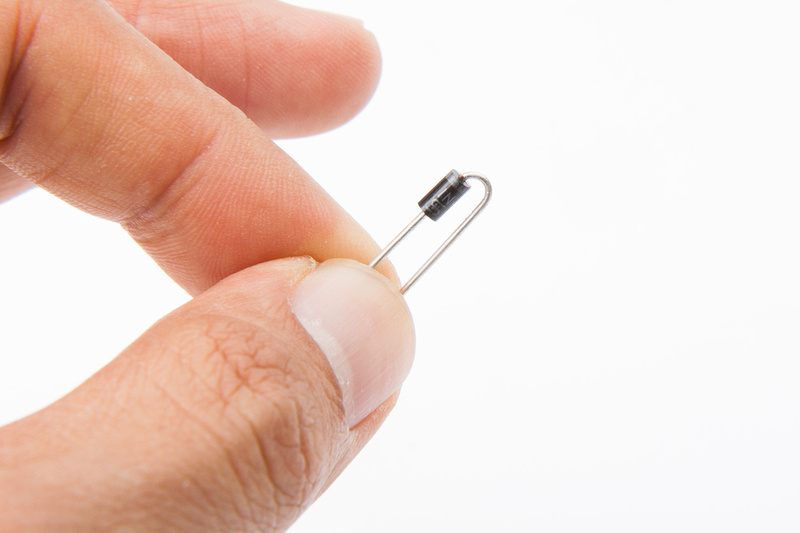

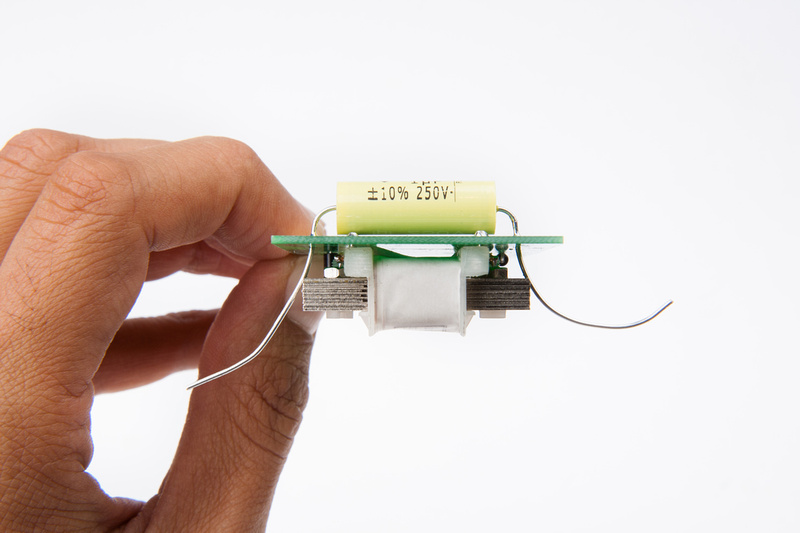

from input others have given who have used this particular toroid, I decide to change my 680R chassis mounted resistor to 1K and to change my 500R 5W pot to 1K as well. This is what people have reported to work, and it's much easier to change the components now before final assembly than later after everything is wired in.

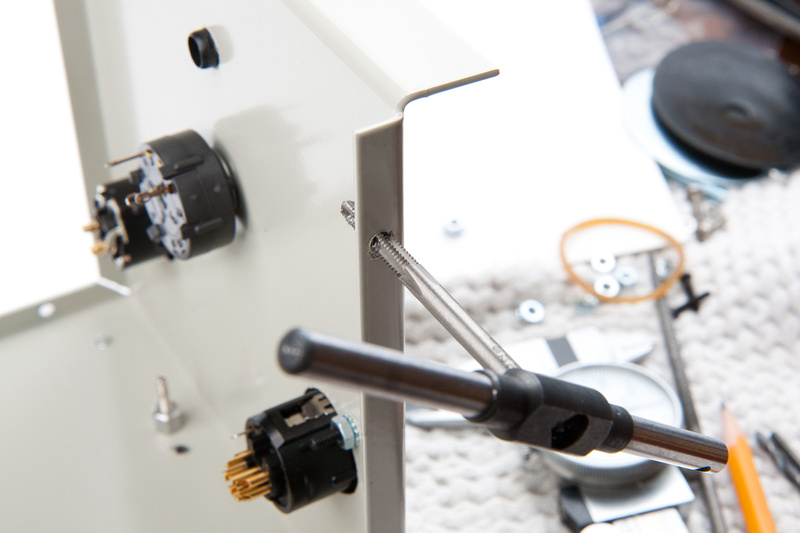

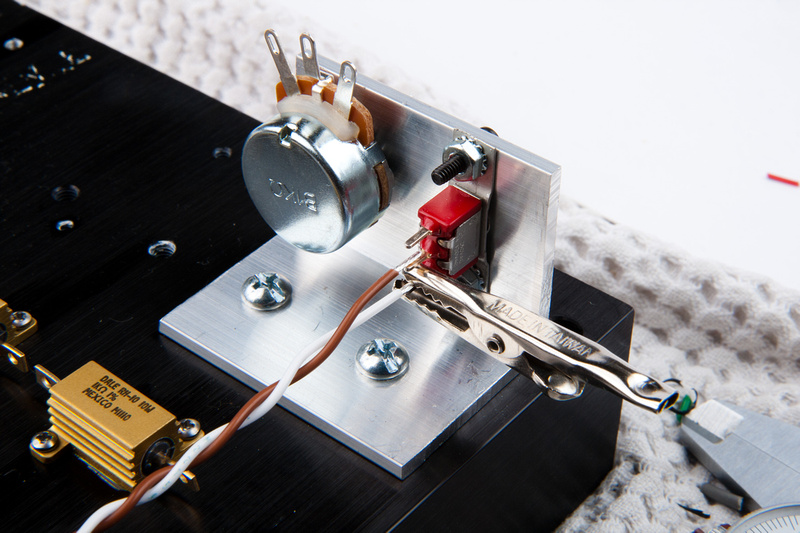

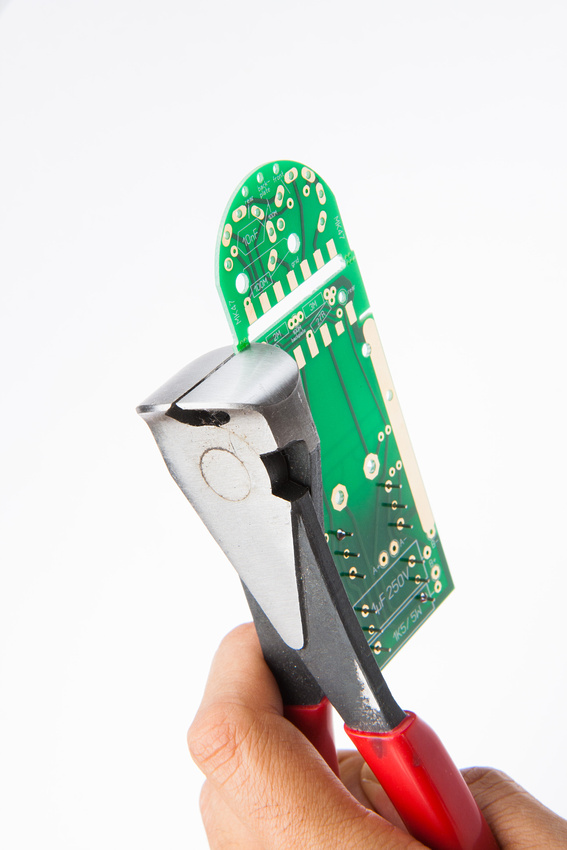

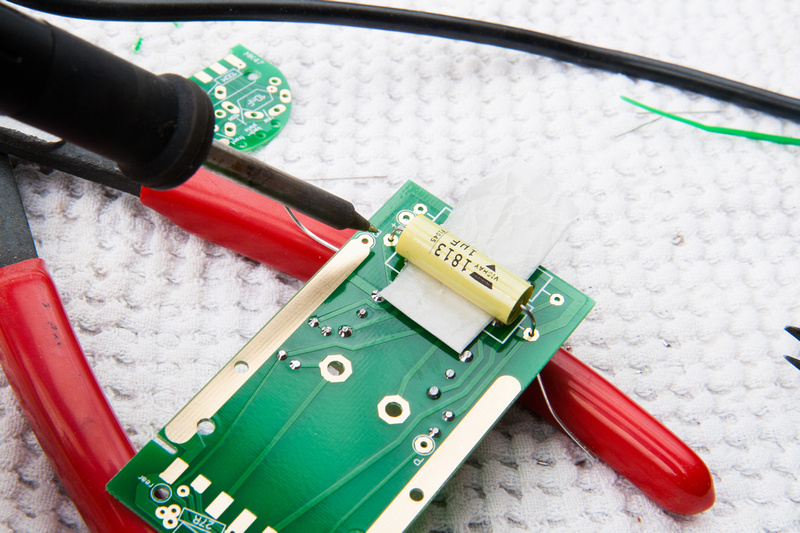

This is how I set up to solder my "hacked" test switch as it does not have solder lug holes.

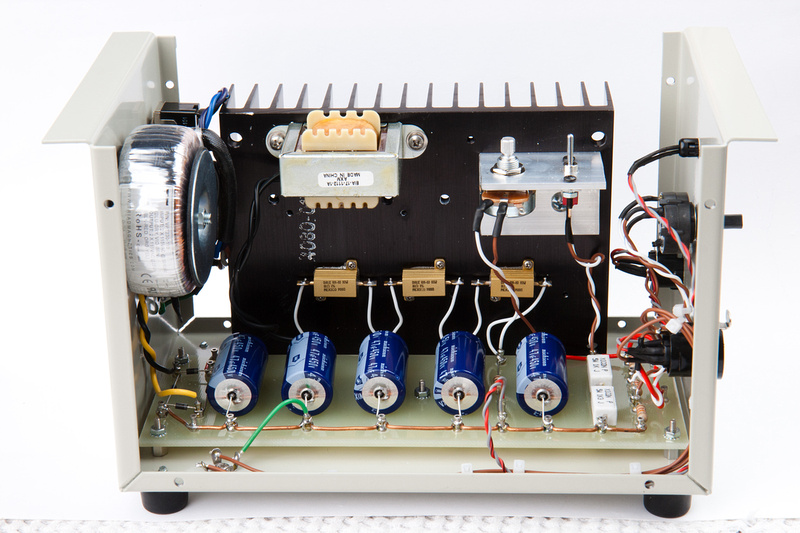

And, the heat sink assembly goes in. Notice I have removed the choke to allow easier soldering on the chassis-mount resistors.

resistors are wired in.

voltage trim pot and test switch are wired in.

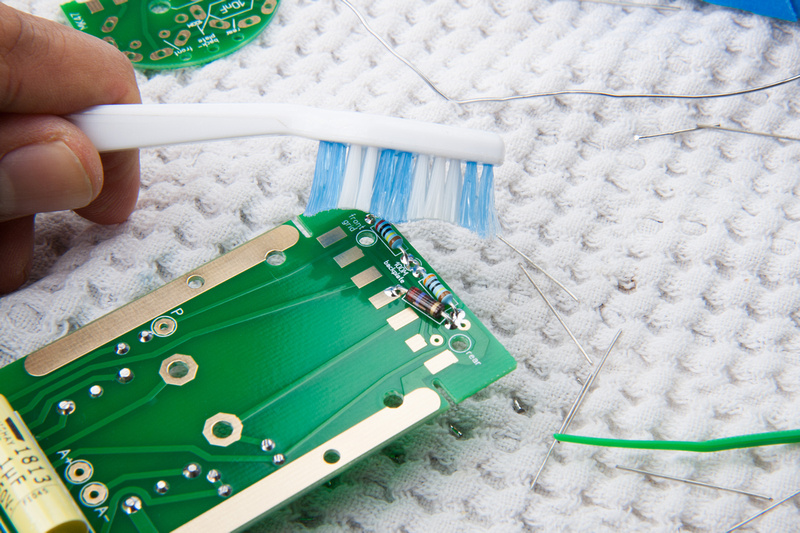

and I install the choke loose first for better access to the solder points.

and mount the choke.

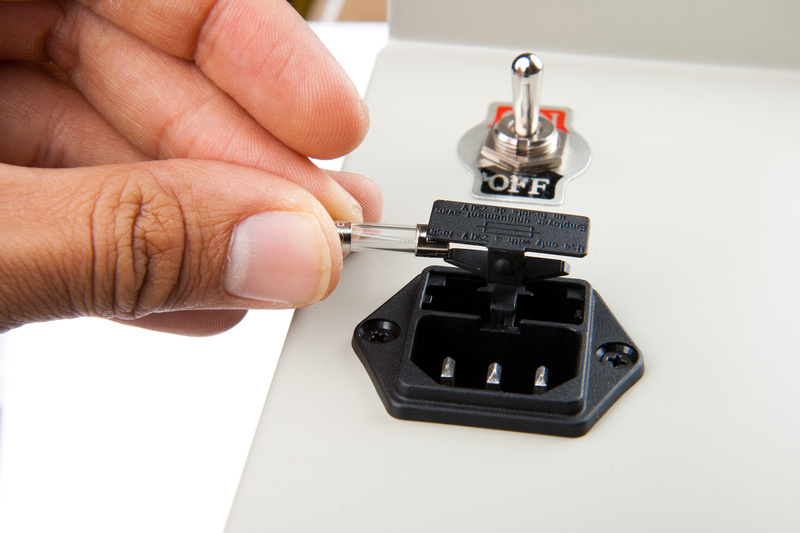

spare fuse goes in the IEC.

and then main fuse.

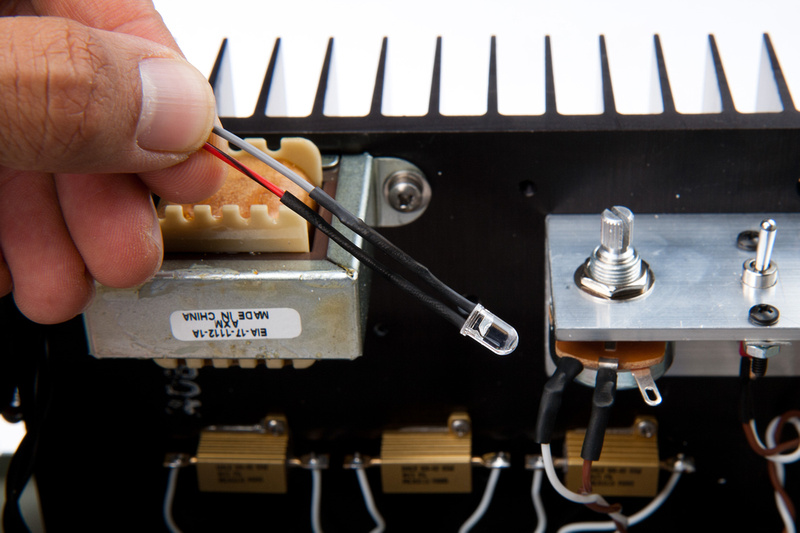

NExt, I prep my LED for installation. Due to discussions on this thread regarding LED power consumption, prior to connecting the LED, I mearure its current draw on my DMM, and it is drawing 1.5mA which I'm happy about. This means the LED is not sapping too much of my power.

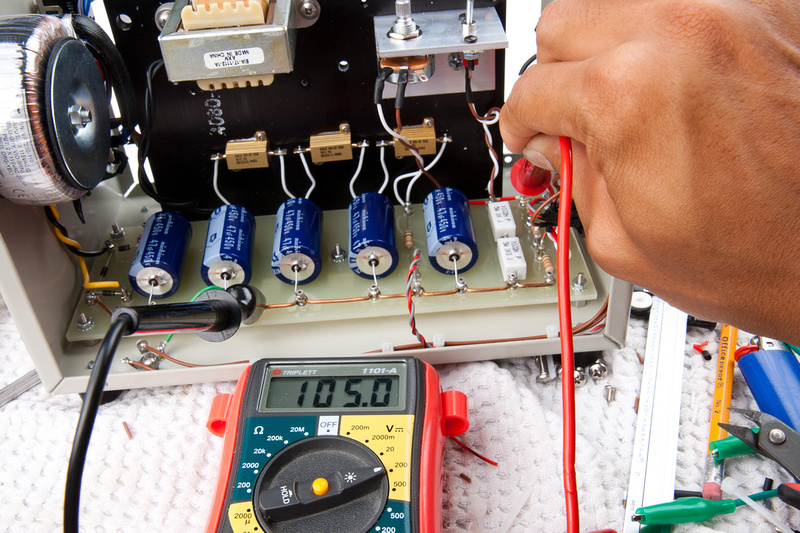

Test mode engaged, I trim out the PSU for 105V. . . spot on. The PSU initially powered up at 116 with the pot somewhere middle-ish.

Humans win!

Next, I flip the test switch to "operate" mode and install the enclosure cover with some 8-32 screws.

last step is to install a little chicken knob on the pattern select switch that I picked up at a local electronics store.

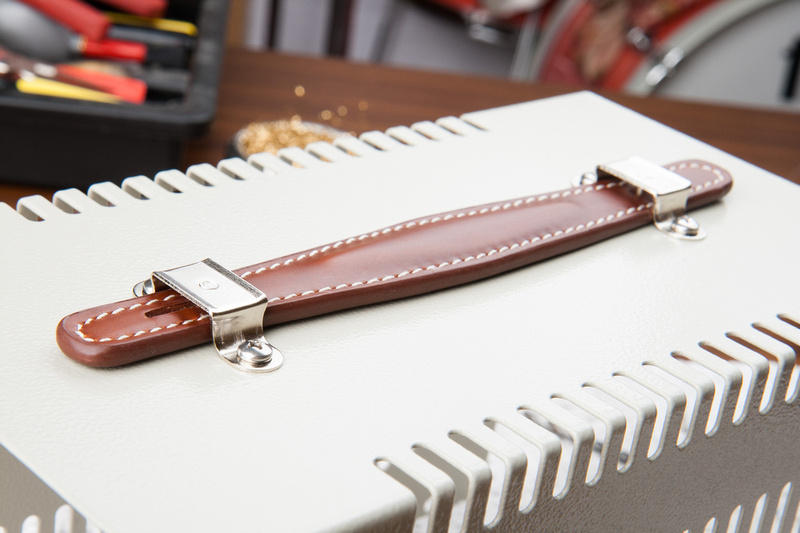

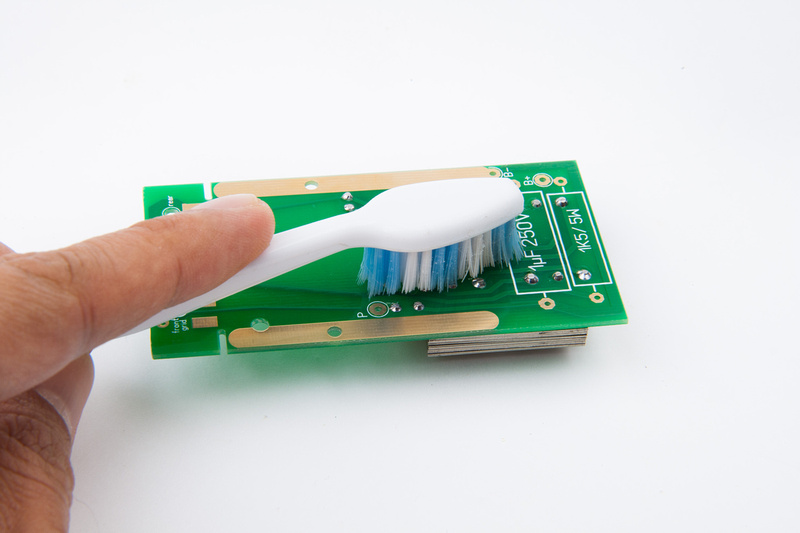

And there it is. . . a successful point to point PSU build for the MK47 microphone. I just need to add a handle of some sort on top. . . I'll probably use a fake leather guitar amp handle of some kind from ebay. All in all, I learned a bit. A few Mouser orders, a few wrong parts, a little scrambling around house looking for screws and tid-bits, but in the end, I'm pretty happy with the result and feel like it should stand up to heavy use. The test resistors do indeed get hot, but that will not be inline under normal use. The only thing I don't really like is the trimmer pot also heats up a bit. It is connected to a thick Aluminum L-bracket so that helps a bit, but I might think about upping the chassis-mounted resistor values as those are running VERY cool in this configuration. Not even warm to the touch.

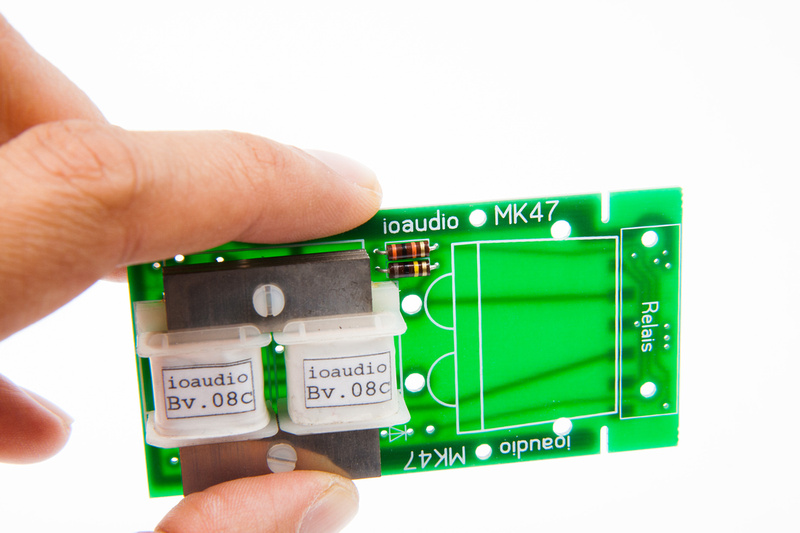

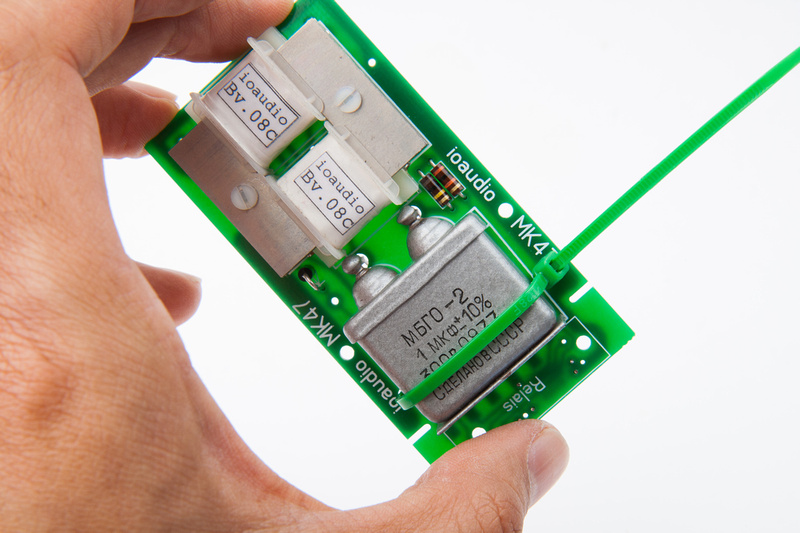

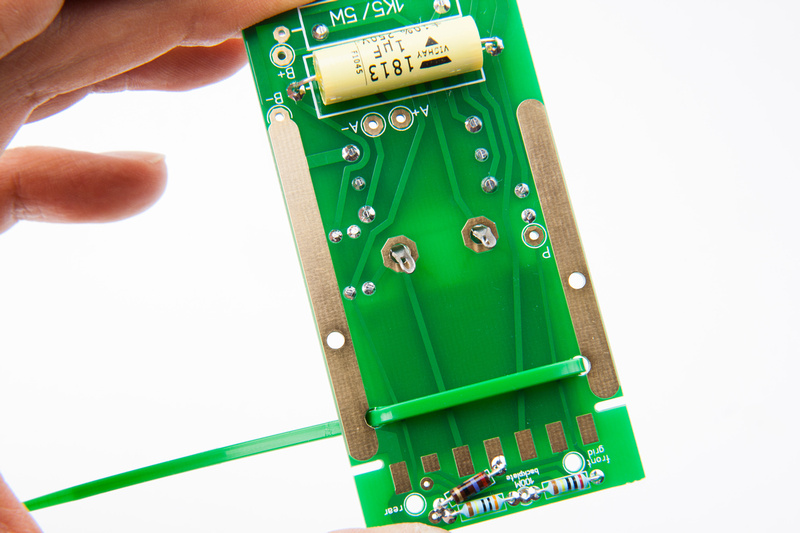

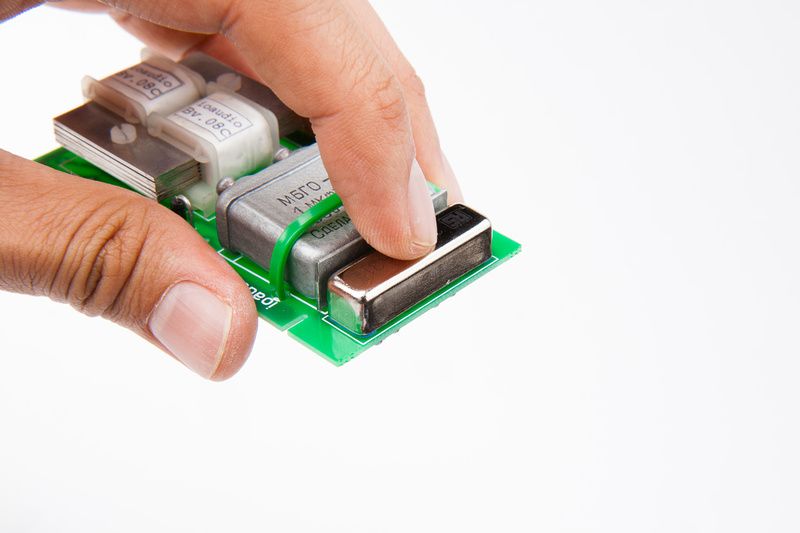

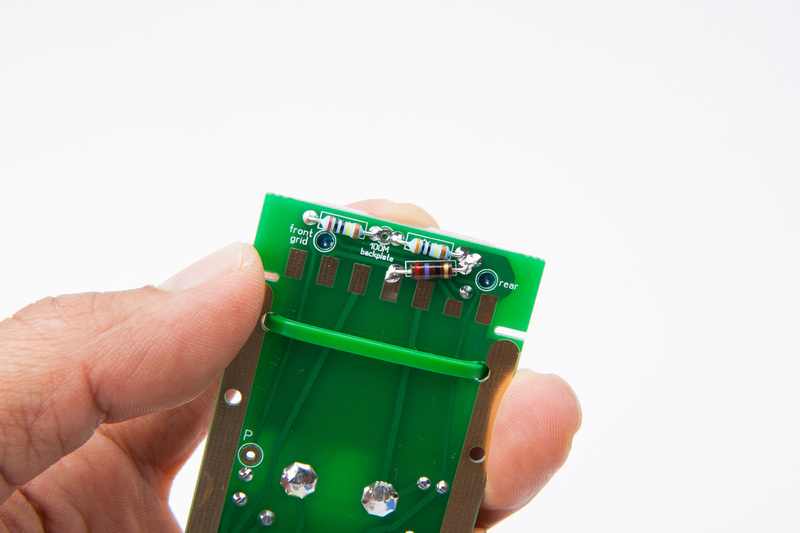

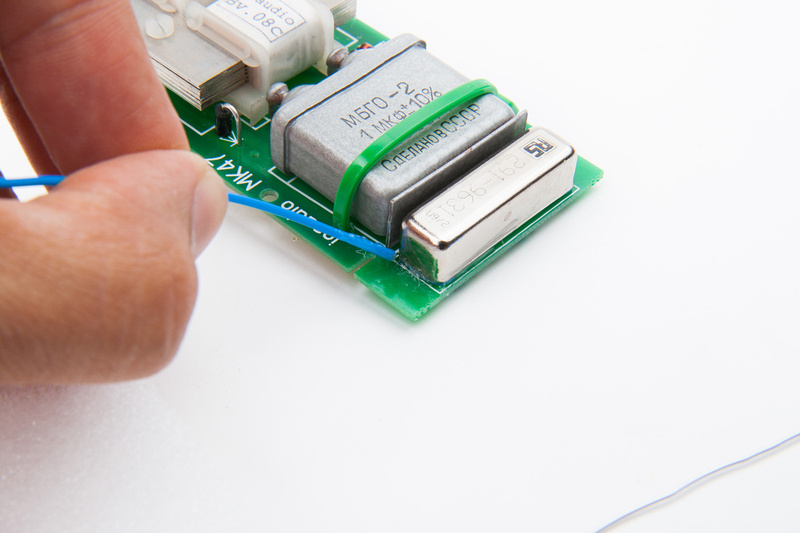

Next, I will look to do a PCB build as I await my donor bodies (unmarked Alctron GT-2B's) that will be inbound directly from the motherland.

This PSU was the main hurdle for me for this project as information seemed to be a bit more scattered. Hopefully, it will be downhill from here with a little bit of luck and a steady hand.