[silent:arts]

Well-known member

yes, but don't use the 40V version. all over 80V are fine.Ptownkid said:1.5 AMP is plenty for the 48V regulator right? In case anyone is wondering, the package type for that reg is called WOG

yes, but don't use the 40V version. all over 80V are fine.Ptownkid said:1.5 AMP is plenty for the 48V regulator right? In case anyone is wondering, the package type for that reg is called WOG

SK-104-38.1RedNoise said:Do someone know the pitch for the heatsink please ?

Sk129 ?

me too ;D ;D ;Dultra-alex said:great idea. cemal, do have any L-brackets left? i´d like one too...

[silent:arts] said:SK-104-38.1RedNoise said:Do someone know the pitch for the heatsink please ?

Sk129 ?

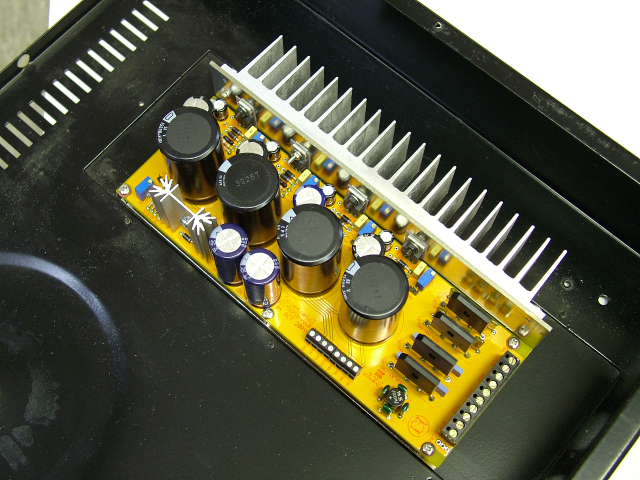

Ptownkid said:As long as it's for a to-220, and fits in a 2u chassis, and has the pcb posts 1 inch (24.5mm) apart, you're golden.

http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=HS346-ND

unless you like smokePtownkid said:THERE HAS TO BE AN INSULATOR BETWEEN YOUR REGS AND THE HEATSINK/CHASSIS!!!

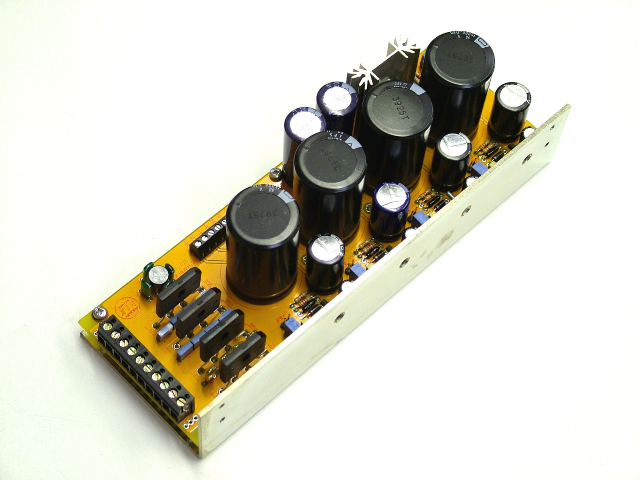

[silent:arts] said:Cemal, I hope it is ok posting your great mounting idea 8)

Enter your email address to join: