You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

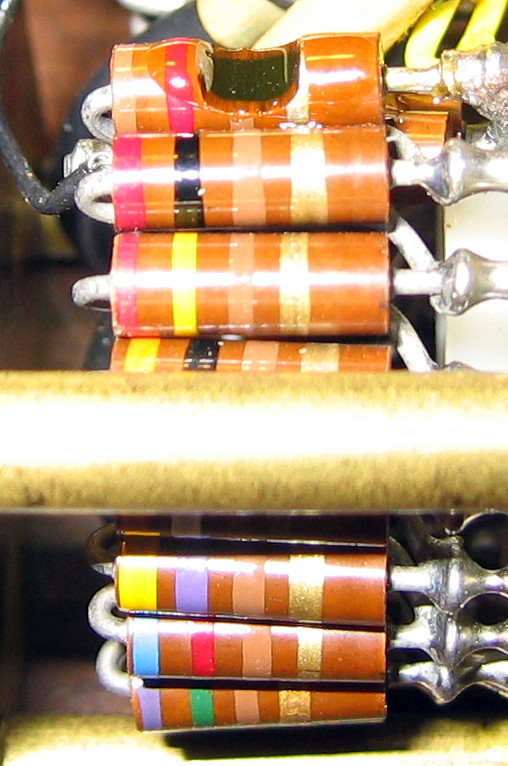

Seen a manually trimmed resistor recently?

- Thread starter emrr

- Start date

Help Support GroupDIY Audio Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

melville

Well-known member

What madness is that? What does it achieve? I'm curious now.

kilmister

Well-known member

Haven't seen but heard (might be rumor but makes perfect sence tought) that this is still common in nuclear power plants where values have to be very very accurate and even small tolearances aren't acceptable.

-Paavo

-Paavo

pucho812

Well-known member

Looks like someone accidently dropped and or left the solder iron on it.... thats crazy

The desired value is probably 148 ohms.

Maybe a 150 is close enough, maybe not, or maybe they ran out of 150s.

If you run a file into the core of a carbon-composition resistor, take some carbon out, the resistance goes up. This is a 120 ohm raised 23%. You work with an ohm meter connected. Take a stroke and lift the file, read the meter, repeat until you have 148 ohms. You must seal the nick or resistance will wander with the weather.

It will still wander with age just because carbon-comp does that.

Daven et all didn't do such things. They had a spool of fine heater wire and scraps of cardboard. They calculated 123 turns, threw 115 turns around the cardboard, then applied the meter to one end and slid the probe along the free length until they got the exact reading. Cut there, wind the loose end on the cardboard, terminate.

That lead-bending is nicely done.

I just got back from the NE Telephone Museum. You want wire? They have 1/10th of a town central office relay switch-gear (500 lines salvaged from a 5,000 line CO) and the wire harnesses make me dizzy. They have a truck-box relay switcher used on an island with 34 customers; even that's a lot of wire.

Maybe a 150 is close enough, maybe not, or maybe they ran out of 150s.

If you run a file into the core of a carbon-composition resistor, take some carbon out, the resistance goes up. This is a 120 ohm raised 23%. You work with an ohm meter connected. Take a stroke and lift the file, read the meter, repeat until you have 148 ohms. You must seal the nick or resistance will wander with the weather.

It will still wander with age just because carbon-comp does that.

Daven et all didn't do such things. They had a spool of fine heater wire and scraps of cardboard. They calculated 123 turns, threw 115 turns around the cardboard, then applied the meter to one end and slid the probe along the free length until they got the exact reading. Cut there, wind the loose end on the cardboard, terminate.

That lead-bending is nicely done.

I just got back from the NE Telephone Museum. You want wire? They have 1/10th of a town central office relay switch-gear (500 lines salvaged from a 5,000 line CO) and the wire harnesses make me dizzy. They have a truck-box relay switcher used on an island with 34 customers; even that's a lot of wire.

melville

Well-known member

Thanks for the explanations. I'm impressed with both the thought process and skills involved to do that.

Clever manipulation of what parts are to hand I guess.

Clever manipulation of what parts are to hand I guess.

Matthew Jacobs

Well-known member

Thanks Emrr for showing this and thanks PRR for explaining how it's done.

I'm definitely gonna do this to get precise carbon comp values in my 1176 rev A sidechain amp, which I'm building with only carbon comps. So far I've been buying loads and finding the ones with the right value. Still missing a few, so this technique will work a treat.

What's the best sealer to use? Will my wife's nail polish do the trick?

J

I'm definitely gonna do this to get precise carbon comp values in my 1176 rev A sidechain amp, which I'm building with only carbon comps. So far I've been buying loads and finding the ones with the right value. Still missing a few, so this technique will work a treat.

What's the best sealer to use? Will my wife's nail polish do the trick?

J

kilmister

Well-known member

[quote author=Matthew Jacobs]

What's the best sealer to use? Will my wife's nail polish do the trick?

[/quote]

I would go with epoxy glue. Stuff in picture looks like that.

-Paavo

What's the best sealer to use? Will my wife's nail polish do the trick?

[/quote]

I would go with epoxy glue. Stuff in picture looks like that.

-Paavo

horvitz

Well-known member

PRR said:I just got back from the NE Telephone Museum. You want wire? They have 1/10th of a town central office relay switch-gear (500 lines salvaged from a 5,000 line CO) and the wire harnesses make me dizzy. They have a truck-box relay switcher used on an island with 34 customers; even that's a lot of wire.

Where is this? BA used to have a small museum in their presentation center in Framingham, but that's gone now. I'd love to go see!

For other wiring goodies, if anyone can ever talk themselves into the Boston Fire radio center, all the terminations for the old citywide pull alarm system are still there. You actually open the door on the side of a huge box and walk inside where if you've had too much for lunch you can't even walk sideways. It is a thing of amazing beauty! The time that must have been spent on this 100 years ago just blows my mind. That's dedication to doing a job well, where mostly it isn't ever seen.

leswatts

Well-known member

I trimmed many film capacitors this way for an electronic crossover once. You just sand them down from the edge,

lowering the capacitance. The sanding shorts the layers though, and you have to "clear them" by sticking the leads in a 120 electrical outlet.

Works for typical 50-100WV caps anyway. An engineer at our Packtron capacitor division taught me this.

Sealed with epoxy.

Les

lowering the capacitance. The sanding shorts the layers though, and you have to "clear them" by sticking the leads in a 120 electrical outlet.

Works for typical 50-100WV caps anyway. An engineer at our Packtron capacitor division taught me this.

Sealed with epoxy.

Les

Kingston

Well-known member

haha!

leswatts

Well-known member

I used to write code to laser trim resistors and pots to linearity, value, TCR, etc. a lot. I could do just as well on prototypes

with a dremel or scribe.

You can still do it easily to thick film devices. There's a trick. First do a rough plunge trim, but not quite up to value.

On either side this makes areas of lower current density...a "shadow" if you will. If you then fine trim there (the flanks of the

first trim) you can get the value right to the ohm or even better if your measurement device is good enough.

I got perfectly unreasonable doing this though. Obsessive compulsive? I'd get it so close that I had to wait a few moments after each cut...

the heat of the dremel would temporarily raise the resistance very slightly,and I had to let it settle.

Les

with a dremel or scribe.

You can still do it easily to thick film devices. There's a trick. First do a rough plunge trim, but not quite up to value.

On either side this makes areas of lower current density...a "shadow" if you will. If you then fine trim there (the flanks of the

first trim) you can get the value right to the ohm or even better if your measurement device is good enough.

I got perfectly unreasonable doing this though. Obsessive compulsive? I'd get it so close that I had to wait a few moments after each cut...

the heat of the dremel would temporarily raise the resistance very slightly,and I had to let it settle.

Les

leswatts said:I trimmed many film capacitors this way for an electronic crossover once. You just sand them down from the edge,

lowering the capacitance. The sanding shorts the layers though, and you have to "clear them" by sticking the leads in a 120 electrical outlet.

Works for typical 50-100WV caps anyway. An engineer at our Packtron capacitor division taught me this.

I love it! Clearing with 120AC. Things 5 year olds should never know.....

Similar threads

- Replies

- 12

- Views

- 462

- Replies

- 2

- Views

- 223

- Replies

- 3

- Views

- 241