the idea is to make an Open Source Hardware & Software,

to control Analog Audio Hardware with Digital signals, like a dummy plugin that has Total Recall in VST, AAX & AU.

WesAudio already has a similar project, but is Not designed to retrofit older vintage equipment, its designed for New HW.

by USB

but the principle is similar / same..

to modify existing hardware and clones from any manufacturer...

and be able to control it

like mixanalog.com

by Ethernet

but open source.

Digitally controlled Analog.

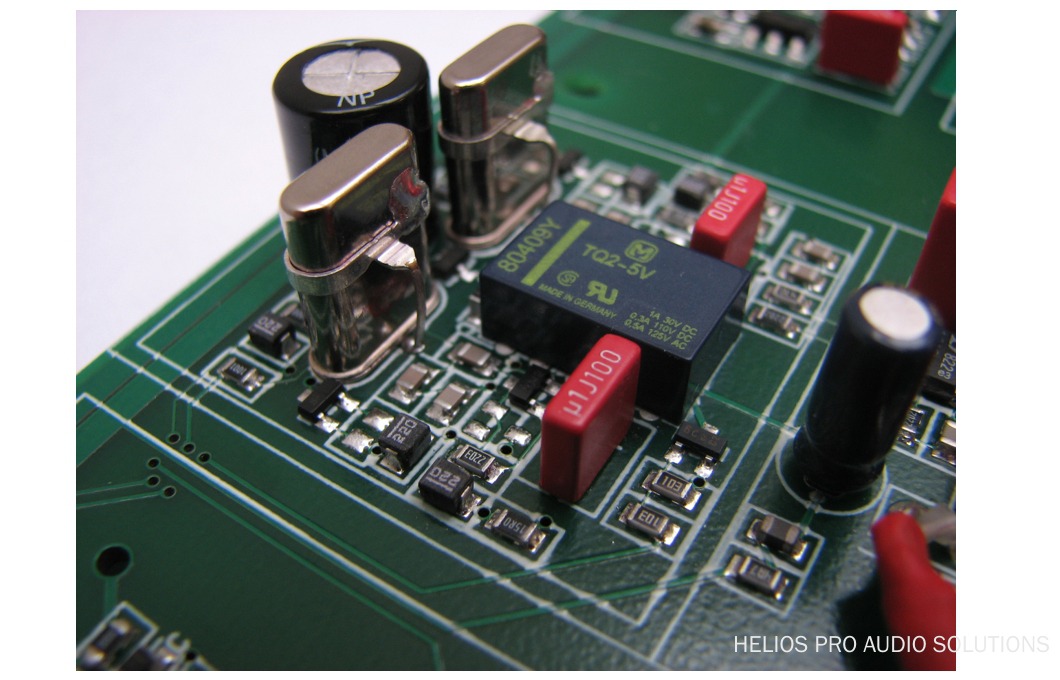

Relays, VCA, AD, & DA are basically the building blocks for the HW,

the hard part is the Software, because it also needs to download the Steiberg & Avid developer SDK.

maybe a Stand alone version would be enough, for version 1.0

Requirements:

Must Be OSX, Windows & Linux/FreeBSD compatible... "Multi Platform",x86_64 & RISC. "future proof."

Must be OSX Maverics compatible 10.9.5 minimum.. "backward compatible" compiled with older version of Xcode.

preferably OSX 10.6.8 SnowLeopard compatible...

must be as compatible as possible.

must be as low latency as possible, RealTime if possible.

must have common parts, time proven, time tested, Not obscure or very obsolete.

i think this is the future...

McDSP the plugin company is also making a Digitally Controlled Analog HW.

Waldorf had a 16 channel DCA Low Pass Filter Box,

Summit Audio also has a DCA EQ.

like the movie, Back to the Future, where there is a billboard in the future, to convert any vehicle to a flying car... for $49.999

Not MIDI because it has 7-Bits, and thats too little for some things, maybe having an offset to fine tune could work too...

if CC has 156 steps per Hz.

a EQ that can swept from 0Hz to 20050Hz,

at CC 64 would be 10025Hz

at CC 32 would be 5012.5Hz

at CC 63 =9868 Hz

at CC 65 = 10181Hz

at CC 33 = 4855Hz

at CC 31 = 5169Hz

i feel MIDI is too coarse.

Yamaha DSP Factory volume control had a mathematical formula to change the volume smooth between MIDI jumps...

like Lag circuit.

to control Analog Audio Hardware with Digital signals, like a dummy plugin that has Total Recall in VST, AAX & AU.

WesAudio already has a similar project, but is Not designed to retrofit older vintage equipment, its designed for New HW.

by USB

but the principle is similar / same..

to modify existing hardware and clones from any manufacturer...

and be able to control it

like mixanalog.com

by Ethernet

but open source.

Digitally controlled Analog.

Relays, VCA, AD, & DA are basically the building blocks for the HW,

the hard part is the Software, because it also needs to download the Steiberg & Avid developer SDK.

maybe a Stand alone version would be enough, for version 1.0

Requirements:

Must Be OSX, Windows & Linux/FreeBSD compatible... "Multi Platform",x86_64 & RISC. "future proof."

Must be OSX Maverics compatible 10.9.5 minimum.. "backward compatible" compiled with older version of Xcode.

preferably OSX 10.6.8 SnowLeopard compatible...

must be as compatible as possible.

must be as low latency as possible, RealTime if possible.

must have common parts, time proven, time tested, Not obscure or very obsolete.

i think this is the future...

McDSP the plugin company is also making a Digitally Controlled Analog HW.

Waldorf had a 16 channel DCA Low Pass Filter Box,

Summit Audio also has a DCA EQ.

like the movie, Back to the Future, where there is a billboard in the future, to convert any vehicle to a flying car... for $49.999

Not MIDI because it has 7-Bits, and thats too little for some things, maybe having an offset to fine tune could work too...

if CC has 156 steps per Hz.

a EQ that can swept from 0Hz to 20050Hz,

at CC 64 would be 10025Hz

at CC 32 would be 5012.5Hz

at CC 63 =9868 Hz

at CC 65 = 10181Hz

at CC 33 = 4855Hz

at CC 31 = 5169Hz

i feel MIDI is too coarse.

Yamaha DSP Factory volume control had a mathematical formula to change the volume smooth between MIDI jumps...

like Lag circuit.