ramshackles said:

...It seems to be either full gain or no gain - with the pot all the way up, I get nice, full gain. Anything else and nothing...I'm using a log pot where I should be using linear?

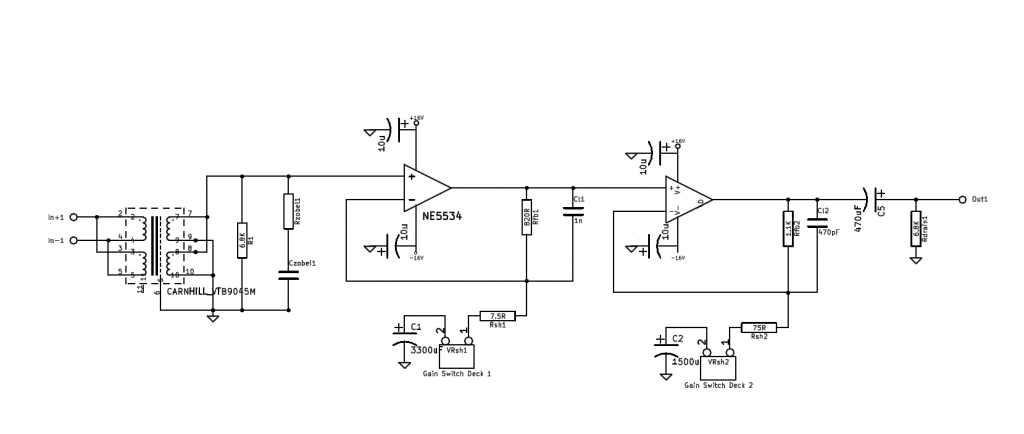

The 'gain pot' is wired as a variable resistor/rheostat for each 'gain switch deck1' and 'gain switch deck2' from schematic.

Just run the numbers for some gain settings in order to see the rheostats value and taper needed at wanted rotation angle

for your (maybe stereo) pot with gain in dB=Log(1+Rfb/(Rsh+Rvar))*20.

Max.gain per stage is set with 0 ohm/shorted out gain switch/rheostat in series to Rsh.

For a more linear dB increase per pots rotation angle (pots come with high tolerances, taper might/will be far from perfect,...),

maybe use a max.rheostat value of Rfb-Rsh, giving a min.+6dB gain per gain stage.

I'd ignore the theoretical 0dB min.gain setting by infinite resistance/open connections at the gain switches,

so the (unity gain stable compensated) opamps would operate as unity gain followers instead, but YMMV.