My studio mate asked me to build a dual channel tube mic pre in 1 RU with internal PSU, so everything must fit in an enclosure of 40 mm height.

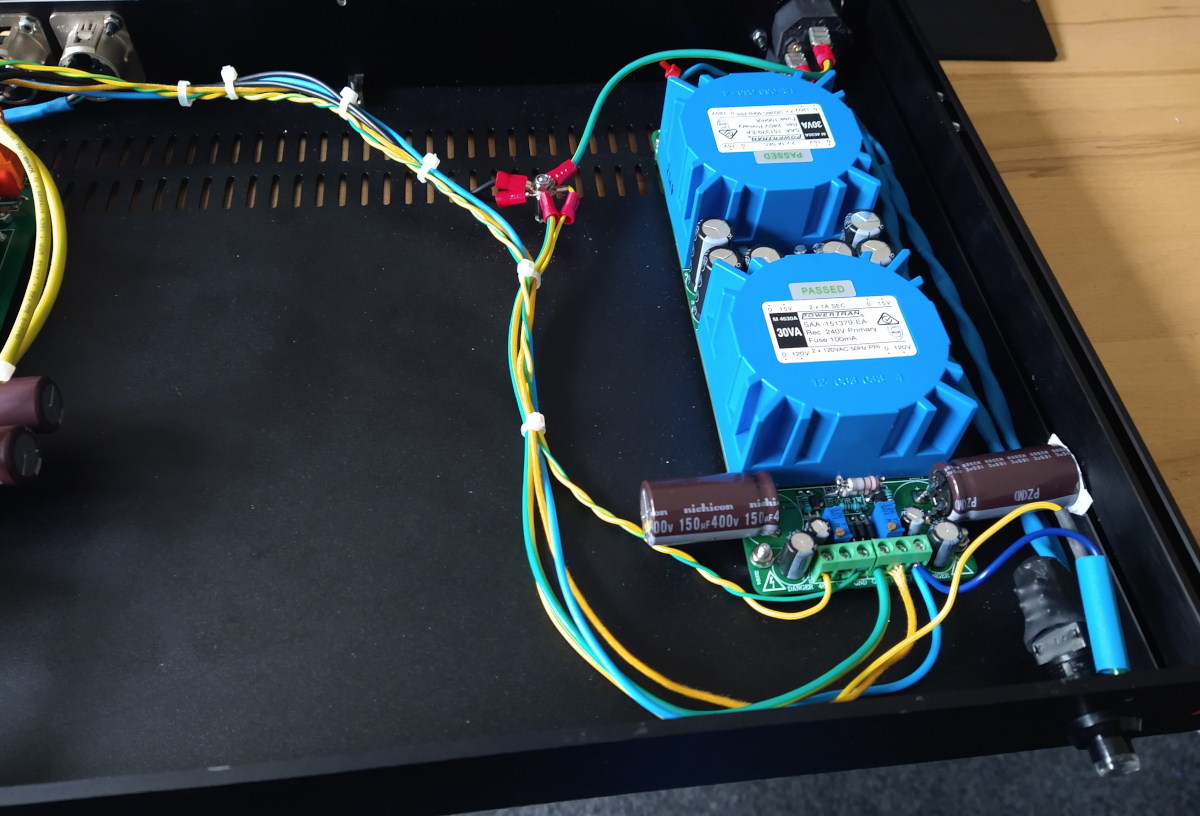

For the amp card it seemed to be managable, but I didn't had an idea for the PSU. Since I had no time to design an own PCB I stumbled over Joe Malone's Scorpion

PSU kit. I gave it a try. After a mail conversation with Joe, who responded fast and comprehensive, the Scorpion worked as expected.

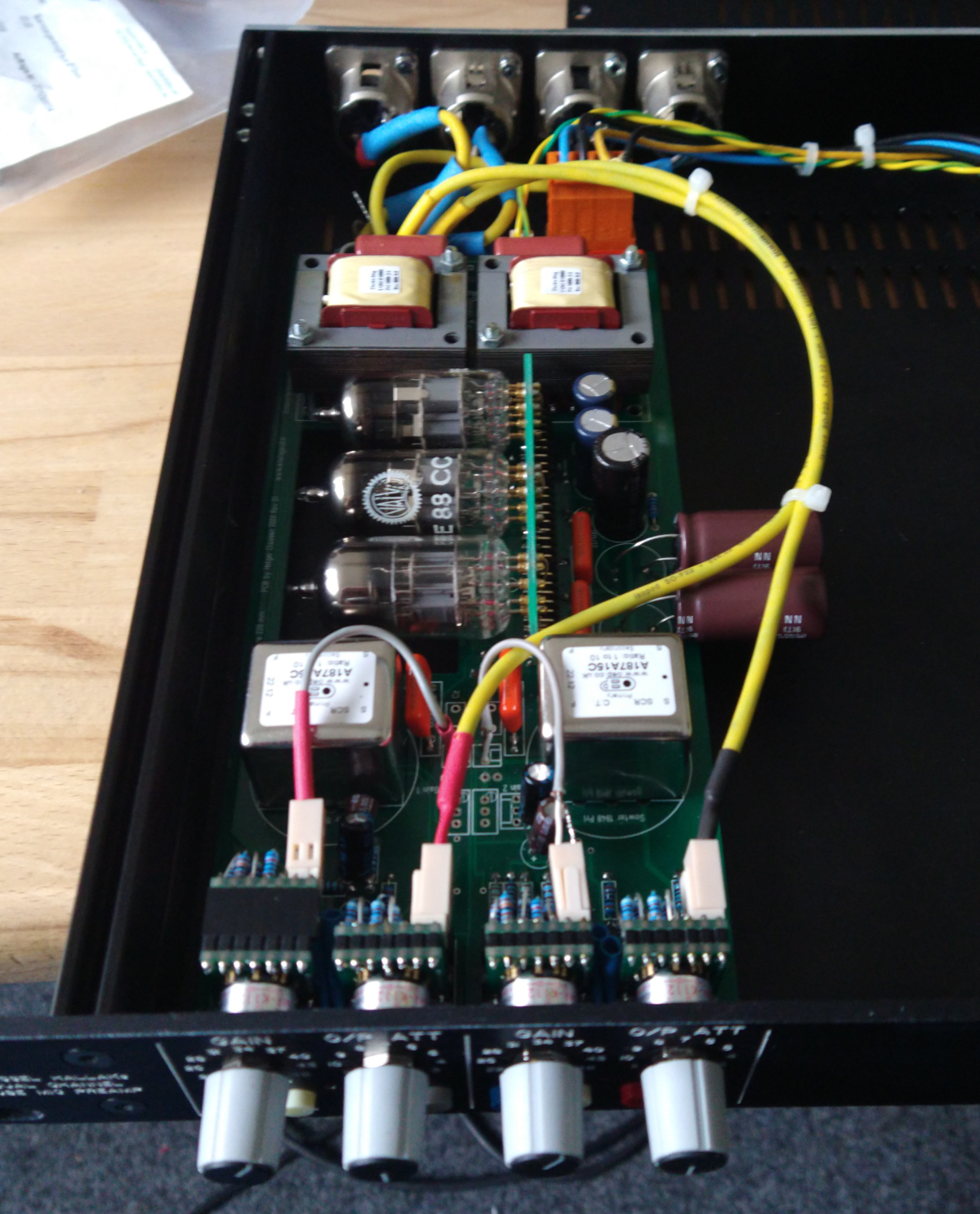

The amp card is the same as in my modular system, it's Ian Thompson-Bell's TLA built as mic pre.

Stepped NKK switches for Gain and O/P attenuation. Found some new old stock Hamburg made Valvo E88CC. Enclosure is from Modushop.

The mic pre works excellent.

![Soldering Iron Kit, 120W LED Digital Advanced Solder Iron Soldering Gun kit, 110V Welding Tools, Smart Temperature Control [356℉-932℉], Extra 5pcs Tips, Auto Sleep, Temp Calibration, Orange](https://m.media-amazon.com/images/I/51sFKu9SdeL._SL500_.jpg)