You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fender Vibrolux Reverb DIY

- Thread starter CJ

- Start date

Help Support GroupDIY Audio Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

tracing out the board with a hi-liter pen, checking all the wires and components , a simple but effective technique i learned from an engineer i use to work with, i do not want to pull that board to correct any mistakes,

got the tube side done, just noticed that the yellow wire via in the middle also acts to secure the blue/yellow harness,

got the tube side done, just noticed that the yellow wire via in the middle also acts to secure the blue/yellow harness,

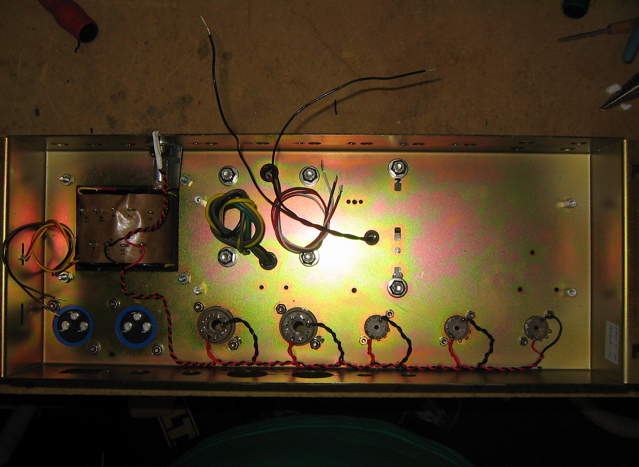

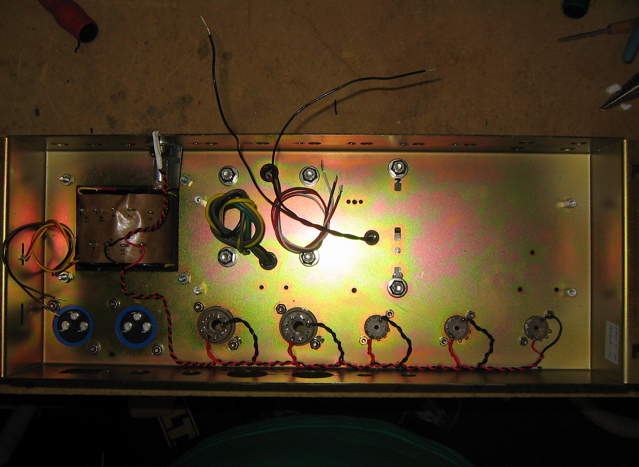

gettin there, got some more work done, i used black and blue wire for the heaters which is non stock, but i can keep the phasing right unlike having green and green, got the dog house all wired up, just wainting for the bias board which somehow disappeared i think i threw it in the garbage by mistake,

Matador

Well-known member

The only way heater hum cancels in a twisted pair is if the two currents (one 'outgoing' and one 'incoming') are equal and opposite in magnitude.

It's clear when you see a picture like this:

Since the wires are two different colors, you can see the incorrect daisy-chain twisting from the first power tube to the second (actually it's wrong for all of them, as clearly shown): if you use one color for 'outbound' and a different one for 'inbound', the two opposite colors should always be twisted together - there shouldn't be sections where a like color are twisted together, since that means there are two 'outbound' currents flowing in the same pair, meaning there is no cancellation happening.

Having a single color for the heater wiring makes this almost impossible to see easily.

It's clear when you see a picture like this:

Since the wires are two different colors, you can see the incorrect daisy-chain twisting from the first power tube to the second (actually it's wrong for all of them, as clearly shown): if you use one color for 'outbound' and a different one for 'inbound', the two opposite colors should always be twisted together - there shouldn't be sections where a like color are twisted together, since that means there are two 'outbound' currents flowing in the same pair, meaning there is no cancellation happening.

Having a single color for the heater wiring makes this almost impossible to see easily.

I do not know who important it is for the preamp tubes. The power tubes run in push pull so having the same peaks and valleys for each tube will hopefully mean that some cancellation is taking place. I never did understand that Marshall wiring but I guess they know what they are doing. Then again, Marshalls can be kind of noisy but nobody noticed because they are always up to 10 with a stomp box in front.

The biggest complaint I get with Marshalls is"it squeals and hums when I stand next to it" so I tell them "have you ever heard that police song called don't stand so close to me?

The biggest complaint I get with Marshalls is"it squeals and hums when I stand next to it" so I tell them "have you ever heard that police song called don't stand so close to me?

Last edited:

I do not know who important it is for the preamp tubes. The power tubes run in push pull so having the same peaks and valleys for each tube will hopefully some cancellation is taking place. I never did understand that Marshall wiring but I guess they know what they are doing. Then again, Marshalls cab be kind of noisey but nobody noticed because they are always up to 10 with a stomp box in front

soapfoot

Well-known member

Nice! If not for the white ceramic octal sockets and blue/black heater wires, you could almost squint and think it's a very clean vintage original

ps_electrik

Member

So, for the push/pull output tubes, wouldn't you want to reverse the heater phase on one of the tubes in order to to get the cancellation?

Thanks!

Thanks!

Freeze time with the top tube heater getting driven by the positive peak of the 6.3 volt supply.

If the heaters are wired correctly, the bottom tube heater will be driven by the same positive peak.

Any hum that drifts from the heater to the grid and gets amplified by the tubes will cancel out inside the output transformer.

This is because you will have a positive peak on the top of transformer primary and a positive peak on the bottom winding. Since there is no potential difference between the top and bottom of the primary, no heater him will be induced into the secondary and it's speaker.

This is confusing because of the top and bottom peaks getting cancelled by twisting the wire in the heater wiring, but in the output transformer, you want a difference in voltage across the primary if you are trying to amplify a guitar, as a potential difference across the primary will mean that current will flow.

Since the transformer is a current operated device, with no voltage difference between the two terminals of the winding as in our correctly wired heaters, no current will flow and so no hum is heard.

This is also why you do not need a ton of filtering in a push pull amp for the power tubes , the transformer will do the same thing with the power supply ripple as it does with the heater hum voltage.

If the heaters are wired correctly, the bottom tube heater will be driven by the same positive peak.

Any hum that drifts from the heater to the grid and gets amplified by the tubes will cancel out inside the output transformer.

This is because you will have a positive peak on the top of transformer primary and a positive peak on the bottom winding. Since there is no potential difference between the top and bottom of the primary, no heater him will be induced into the secondary and it's speaker.

This is confusing because of the top and bottom peaks getting cancelled by twisting the wire in the heater wiring, but in the output transformer, you want a difference in voltage across the primary if you are trying to amplify a guitar, as a potential difference across the primary will mean that current will flow.

Since the transformer is a current operated device, with no voltage difference between the two terminals of the winding as in our correctly wired heaters, no current will flow and so no hum is heard.

This is also why you do not need a ton of filtering in a push pull amp for the power tubes , the transformer will do the same thing with the power supply ripple as it does with the heater hum voltage.

Last edited:

ps_electrik

Member

Thank you!

Do you refrence the heaters to ground through 100 ohm resistors and lift the center tap. Is this better for hum?

i usually use the ct unless i am tweaking an amp with a hum problem,

in some power transformers, the CT provides a sheild from pri to sec to squash line noise, the 6.3 wind being placed between the pri and sec, but modern winders do not use this much anymore,

one advantage to that the resistors will open up if there is the rare shortout from plate to heater,

you can also put a wire wound pot and dial in the hum rejection a bit better, this works good for mismatched tubes,

in some power transformers, the CT provides a sheild from pri to sec to squash line noise, the 6.3 wind being placed between the pri and sec, but modern winders do not use this much anymore,

one advantage to that the resistors will open up if there is the rare shortout from plate to heater,

you can also put a wire wound pot and dial in the hum rejection a bit better, this works good for mismatched tubes,

Last edited:

Matador

Well-known member

In all of my testing, I've never heard any difference noise wise between two 100 ohms and using a native CT.

However there is a massive difference in elevating the CT (whether built-in or virtual with the 100 ohms resistors) - so much so that I've stopped doing DC heaters entirely (except for microphone preamps). Elevating an AB763 cuts noise by almost half (or even better if redoing the twisting), all for the cost of two resistors and a cap.

However there is a massive difference in elevating the CT (whether built-in or virtual with the 100 ohms resistors) - so much so that I've stopped doing DC heaters entirely (except for microphone preamps). Elevating an AB763 cuts noise by almost half (or even better if redoing the twisting), all for the cost of two resistors and a cap.

dmp

Well-known member

What voltage do you elevate the heaters to in a AB763?

Matador

Well-known member

I typically use 50V.

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)