Che_Guitarra

Well-known member

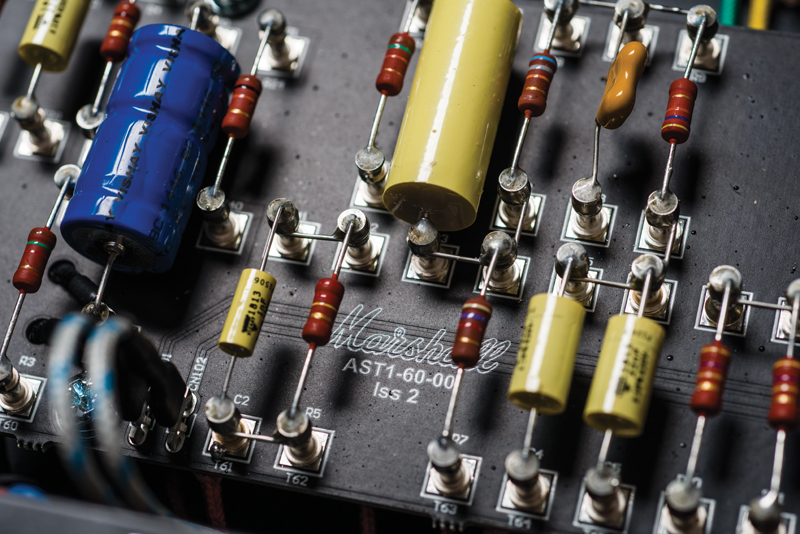

Now the proud owner of an X-Carve CNC machine, I want to put it to use and etch out a PCB for a JCM800 guitar amp project. I've engraved a couple of 19" front panels and they came out surprisingly quite well, so i'm keen to see how it handles the etching of a PCB.

Anyway, i'm digressing...

I'm just wondering how heavy a copper clad I would need on a PCB to suit such a purpose? My local hobby shop has some 1oz copper clad PCB sheets... is this heavy enough?

Anyway, i'm digressing...

I'm just wondering how heavy a copper clad I would need on a PCB to suit such a purpose? My local hobby shop has some 1oz copper clad PCB sheets... is this heavy enough?