Hi there,

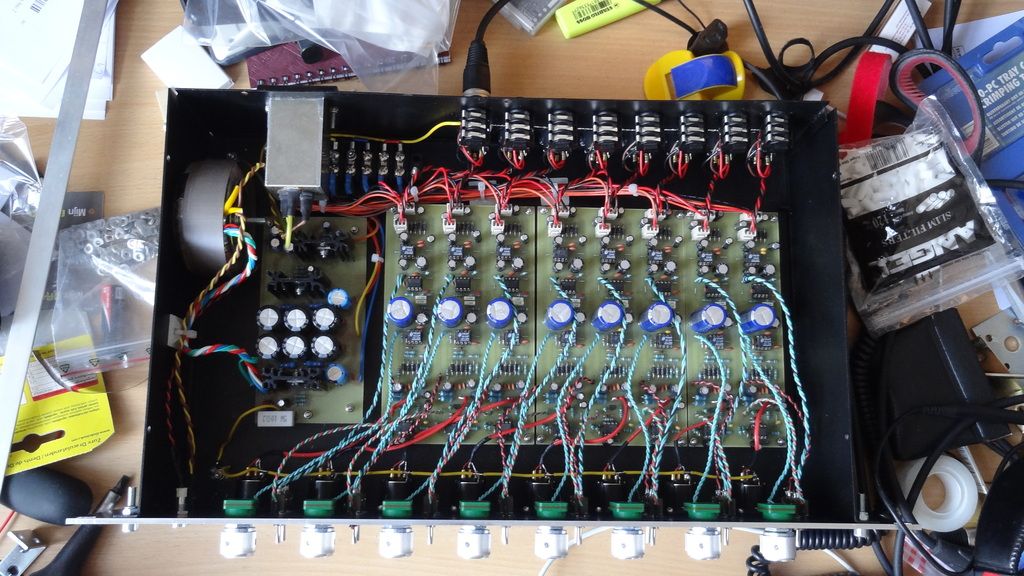

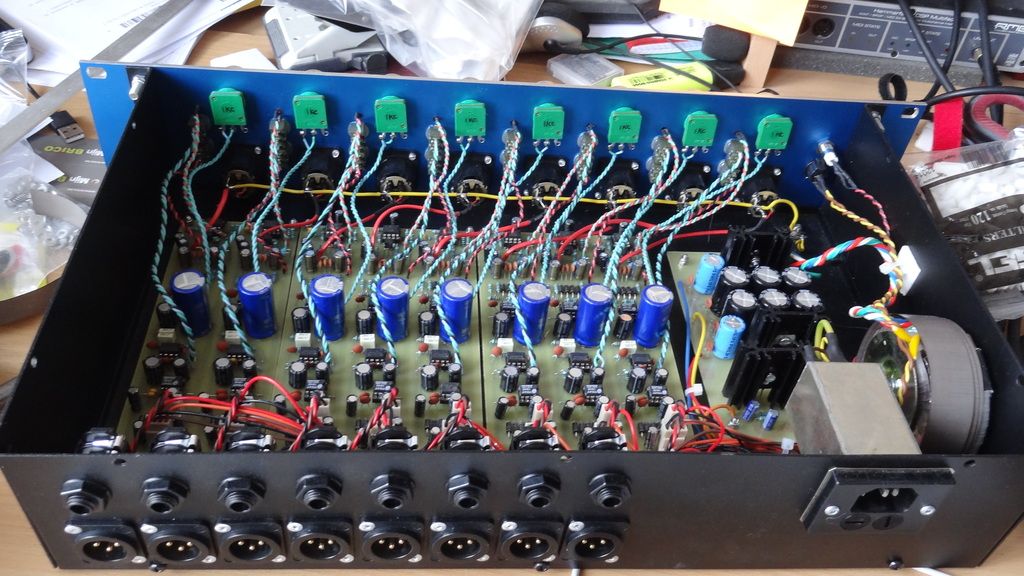

I finally finished building the preamps. I chose to do an 8 version of it.

Here are some pics of the result :

The only thing I'll add is an aluminium bar to attach the wires that connect to the front panel, to relieve the weight on the solders.

Now, some post-build thoughts/comments/interrogations :

- That was a lot of work to build, especially because of all the air wires to the front panel. Although it works perfectly, if I had to do it again I'd make another layout with vertical/double width PCB, switches and pots soldered to it, with care taken not to hace the PCB forcing on the solders.

- Building with vertical and larger / less deep PCBs would allow to move the trafo further away from the preamp circuit, which is always a good thing to avoid magnetically coupled hum.

- Talking about mains trafo, I had a custom low-flux trafo made by Audiophonics (300V->2x20V used with 230V input). With this trafo inplace, at the same place as the current one, the 50Hz hum was buried deep in the hiss, but I had some 150Hz + harmonics stronger than the hiss. This was with 150R resistor across the mic input and the gain all the way up. I first suspected some radiations from the rectifier but it finally appeared that it came from the trafo. I did some tests with a small but thick ungrounded piece of steel, and it could cancel the noise when put in some precise places, though not practical to install permanently. I also tried to deport and move the rectifier without any effect. I then put another trafo I had in stock, and the 150Hz noise disappeared completely !

I don't understand why the custom trafo leaded to more noise, maybe fed back from the rectifier. The only noticeable difference is that it has a screen between primary and secondary, and the one I kept hasn't. There might be some differences in wrapping pattern but I don't have access to those infos

- The preamp is dead silent and has a very flat response.

- I had to wrap the trafo with laminated steel to completely bury the hum into the hiss.

- The power inlet + filter is a Schaffner FN 362-2/05 I had in my drawer. I don't know how useful this is, but I guess it could help keeping the noise down in case of dirty mains. There's 2x5,3mH in series, 2x0,1uF across the line a,d neutral, one before and one after the inductors, and 2x2200pF between line/neutral and earth.

- The output drivers are THAT1646. In some "bad case scenario" test I fed the preamp with a different mains circuit from the RME Multiface soundcard that receives the signal, and I had a STRONG hum ! It could be cured with an isolation transformer, and lifting ground has no effect on it. Could it be due to a mistake I've made ?

- Grounding is done that way : Earth connected to the case, Pin 1 (in&out) connected to the case, audio ground connected to the trafo CT and the trafo CT is connected to the case via 10R/5W // 100nF // 2x1N4007.

- Case engraved by Schaeffer.

That's all ! Please share any comment or critic.

Best regards.

Eric