Hi,

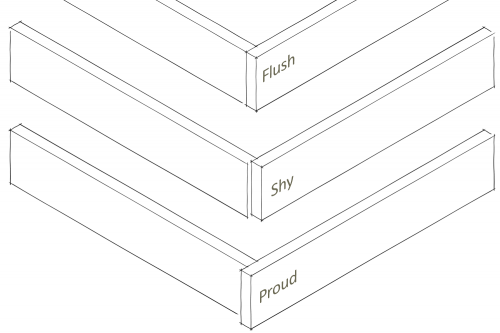

it's the first time I'm using a push button switch, but the action of the switch isn't shown in the technical pdf... usually how many millimeters is it placed compared to the edge of the PCB, considering the thickness of the front panel which is 3mm?

attached the tec pdf, i'm going to use 4pdt and dpdt version same brand...

thanks for your attention and support

it's the first time I'm using a push button switch, but the action of the switch isn't shown in the technical pdf... usually how many millimeters is it placed compared to the edge of the PCB, considering the thickness of the front panel which is 3mm?

attached the tec pdf, i'm going to use 4pdt and dpdt version same brand...

thanks for your attention and support

![Electronics Soldering Iron Kit, [Upgraded] Soldering Iron 110V 90W LCD Digital Portable Soldering Kit 180-480℃(356-896℉), Welding Tool with ON/OFF Switch, Auto-sleep, Thermostatic Design](https://m.media-amazon.com/images/I/41gRDnlyfJS._SL500_.jpg)