efinque

Well-known member

- Joined

- Jan 3, 2018

- Messages

- 368

Sup GDIY,

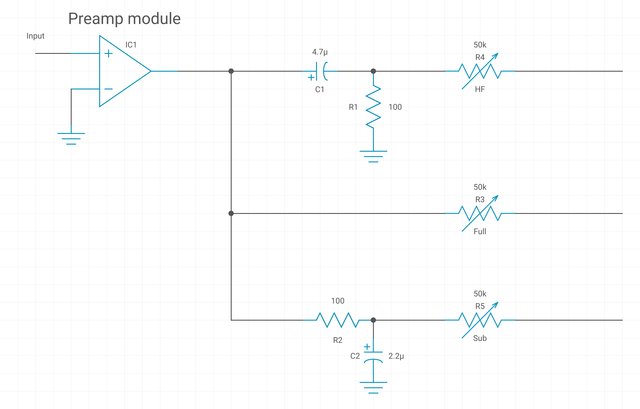

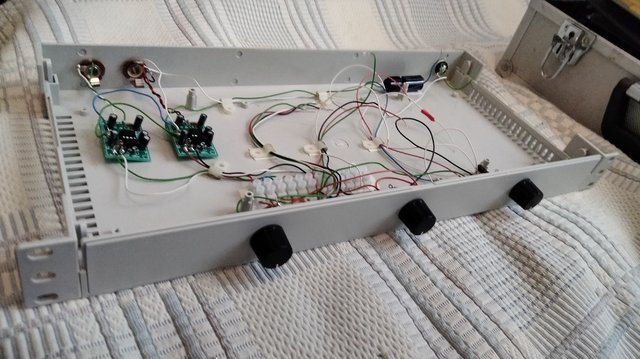

here's a build that's close to being finished, so far it's missing labeling. Afaik the original RLA units had RCA in/out, 24db/oct filters and a fullrange mid band. They were operated from the DJ booth. My take on this has 6,3mm jacks and 6db/oct filters.

The crossover points are 400Hz LF and 800Hz HF.

The preamp section is built from kits, I've yet to test them though. I jumped them with alligator clips to check the freq bands; the filters sounded sweet.

I'll try to post a schematic once I get an EDA software.

Any thoughts?

-ef

here's a build that's close to being finished, so far it's missing labeling. Afaik the original RLA units had RCA in/out, 24db/oct filters and a fullrange mid band. They were operated from the DJ booth. My take on this has 6,3mm jacks and 6db/oct filters.

The crossover points are 400Hz LF and 800Hz HF.

The preamp section is built from kits, I've yet to test them though. I jumped them with alligator clips to check the freq bands; the filters sounded sweet.

I'll try to post a schematic once I get an EDA software.

Any thoughts?

-ef