I've a used TL Audio M3, and all the trimmers for calibration, on the back, were gone out of the holes, maybe because in the years the PCBs have gone a little bent.

So, the only solution [and also for doing the "balance" calibration, only doable with the M3 opened] was to dismantle it.

I'm posting here the photos, because the only way to reassemble the damn thing is to make a little mod, so I'm documenting it.

Here, the 2 visible screws and bolts, like all the others, needs to be removed and no more used [the ground's bolt too]:

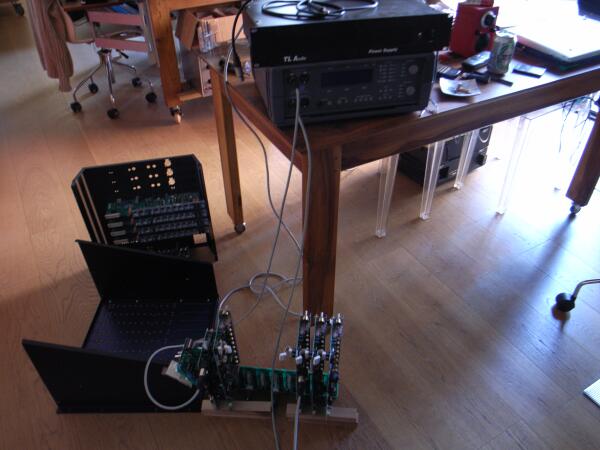

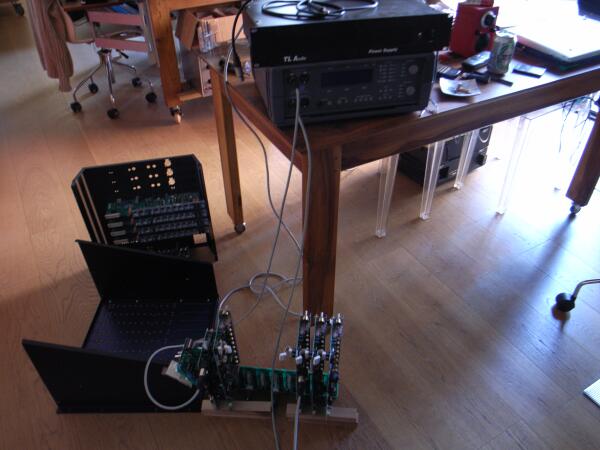

Rearranging the channels for doing the balance calibration:

Pieces of white rubber glued to the metal semi-chassis, against each channel board, for re-align the PCBs and thus the trimmers on the back holes:

New bolts and screws on the rack mounting holes [they replace the impossible-to-use internal ones].

And ground screw in a new made hole.

So, the only solution [and also for doing the "balance" calibration, only doable with the M3 opened] was to dismantle it.

I'm posting here the photos, because the only way to reassemble the damn thing is to make a little mod, so I'm documenting it.

Here, the 2 visible screws and bolts, like all the others, needs to be removed and no more used [the ground's bolt too]:

Rearranging the channels for doing the balance calibration:

Pieces of white rubber glued to the metal semi-chassis, against each channel board, for re-align the PCBs and thus the trimmers on the back holes:

New bolts and screws on the rack mounting holes [they replace the impossible-to-use internal ones].

And ground screw in a new made hole.