tommypiper said:

Guys, are your PCB pads all white? ???

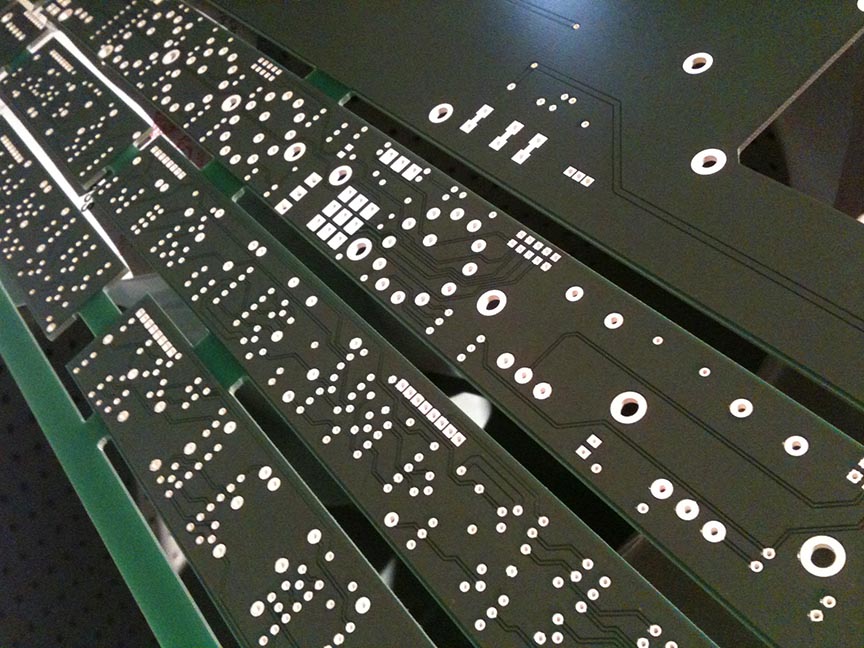

I have never seen something like it. It seems to be paint or a coating on the silver pads, including the through holes, on both sides of the PCB. If I scrape off the coating I see shiny silver underneath. Are we supposed to manually scrape off this coating? Or is it a new high tech thing that burns off with soldering? I don't dare try soldering until I find out what it is... I've asked Gustav but he doesn't seem to know and he thinks it might be me misunderstanding how PCBs are supposed to look, or not seeing the silver correctly.... ??? yeah riiight... so I have to ask you guys. It seems too uniform and clean and white to be oxidization or anything other than intentional masking. But how can this be? Gustav says he checks them when he packages them for shipping... Am I going crazy? The PCBs also seem to be covered with fine oil or a chemical... but what do I know, right?

I'd upload a photo but I don't know how...

See if this works... http://imgur.com/EcRyPYZ

Tommy.

Like I replied to your mail, I was not trying to talk down to you at all. When I call my internet provider with a problem, their first question is always "Is the unit plugged in? Is there a light?". I bet they do that for a reason, and not because they think I am some special branch of stupid.

There are customers who write me, because they are confused about the silver pads, and some are even more so confused, because they are only used to bare copper (as in, why are the pads not brown?). I have no way of assessing your level of expertise (I do not keep a "This "real name" belong to "this user on groupdiy" record") , so my question about your familiarity with commercially manufactured PCBs and the possibility of the silver pads throwing you off was by no means designed to put any kind of blame or talk down to you.

I also did not refer to looking at the rest of the manufactured batch to put you down or shift blame of any problems to you, but simply to try to see if there was some common problem on the current batch of EZ760 boards. If your boards do have some sort of coating on them, I think its prudent to see if it manifest itself on any other boards from the same batch.

I have your pictures, and my suggestion that the silver pads might be throwing you off still stands. I don't see anything wrong with the PCBs in the pictures, and the silver is very milky white, which has thrown off better men than you. If there is some sort of oxidation or coating on the boards which I can not find on the rest of the batch or see on the pictures, I am, of course, still willing to try to figure it out.

I see in my records you got two sets of boards, so I would also like to know if you are having a problem with both boards. Again, this is not to shift any blame or to put you down, but because I am trying to be methodical and help you with your problem.

Feel free to mail me again.

Gustav