T

tubejay

Guest

mnats, what did you think of the sound with the A262A2E in there? I just recieved mine from Newark today, and am hoping it sounds cool. Oh well, it's not too much money lost if I don't like them.

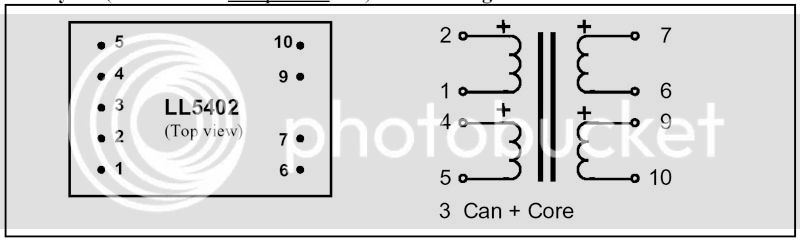

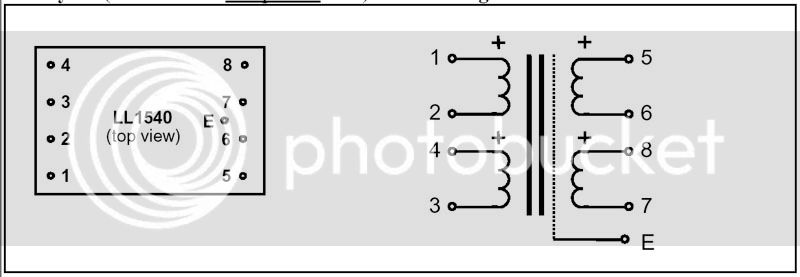

Now...if I could just figure out how to wire this thing up. I'm using Gustav's old boards that don't have the OEP's as an option. Anybody have any input on this. I kind of looked it over a little...and so far I don't really understand which pins go where on Gustav's boards (meaning where do the OEP's correspond with the pins on gustav's boards?)

Now...if I could just figure out how to wire this thing up. I'm using Gustav's old boards that don't have the OEP's as an option. Anybody have any input on this. I kind of looked it over a little...and so far I don't really understand which pins go where on Gustav's boards (meaning where do the OEP's correspond with the pins on gustav's boards?)