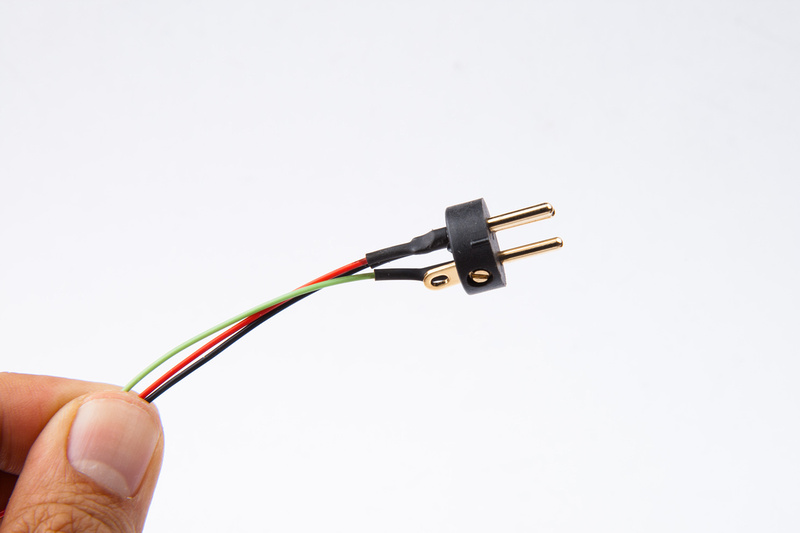

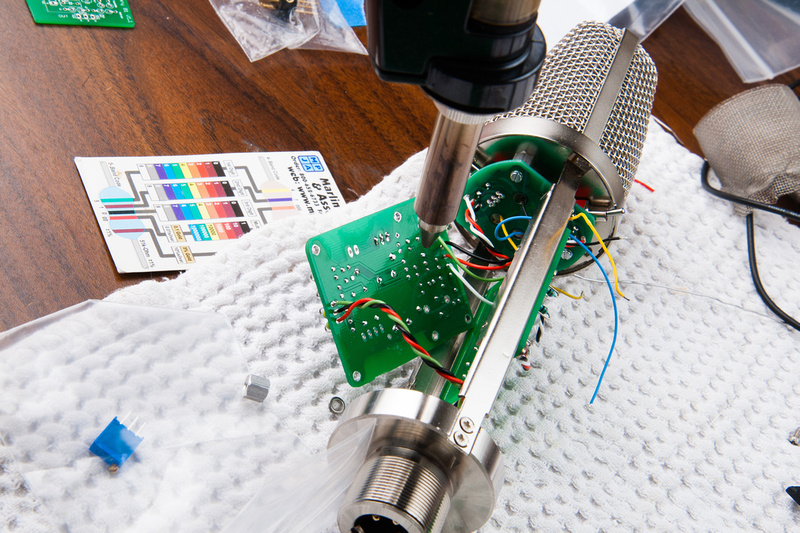

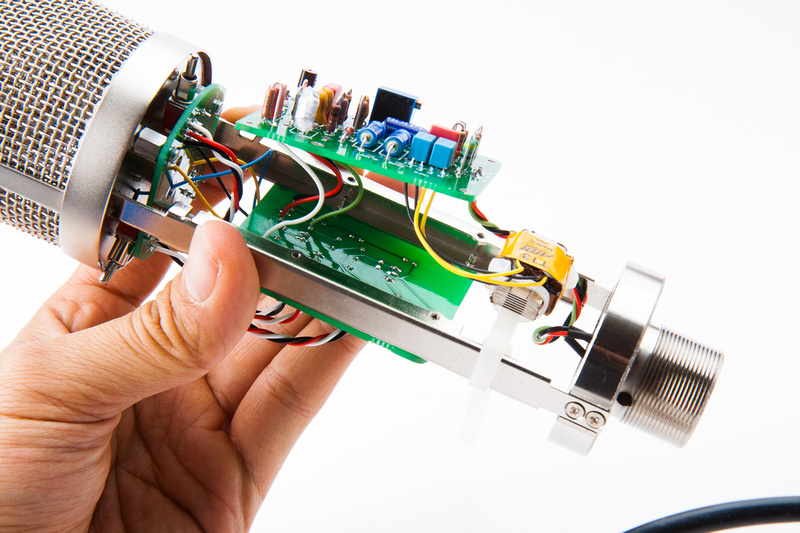

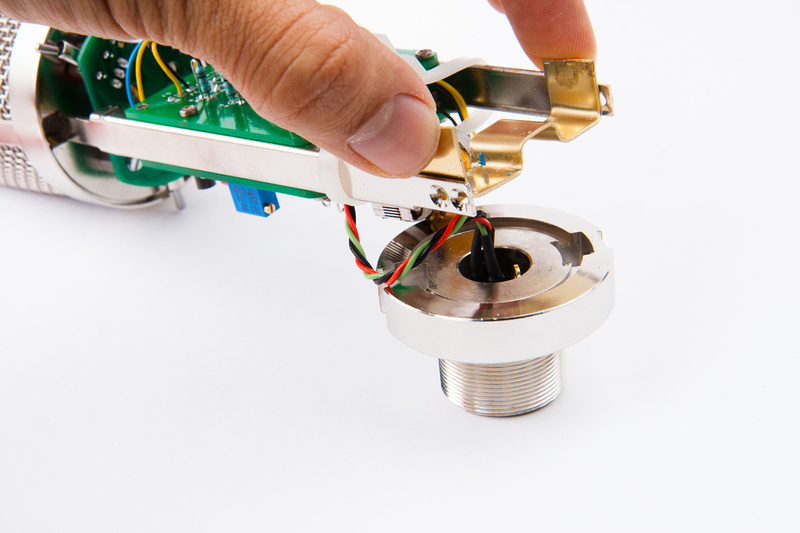

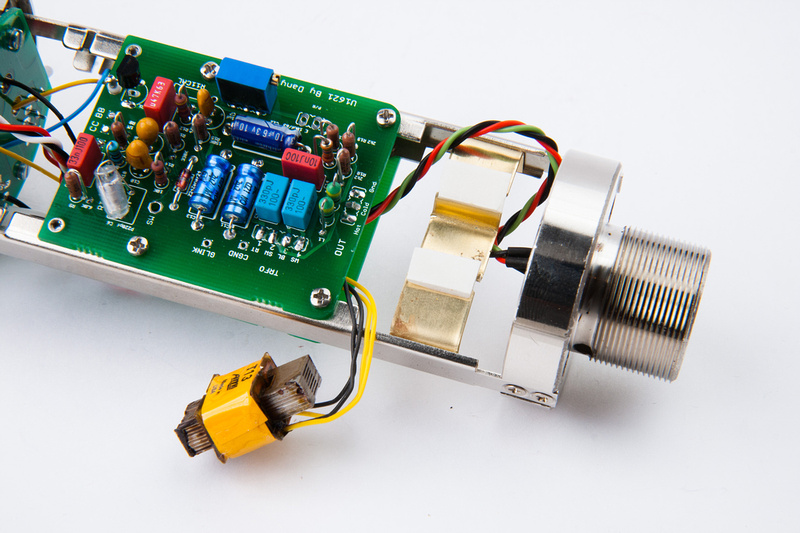

Next, up is the 3 pin XLR insert for the microphone. These bodies are supplied with 3 pin and 7 pin xlr inserts.

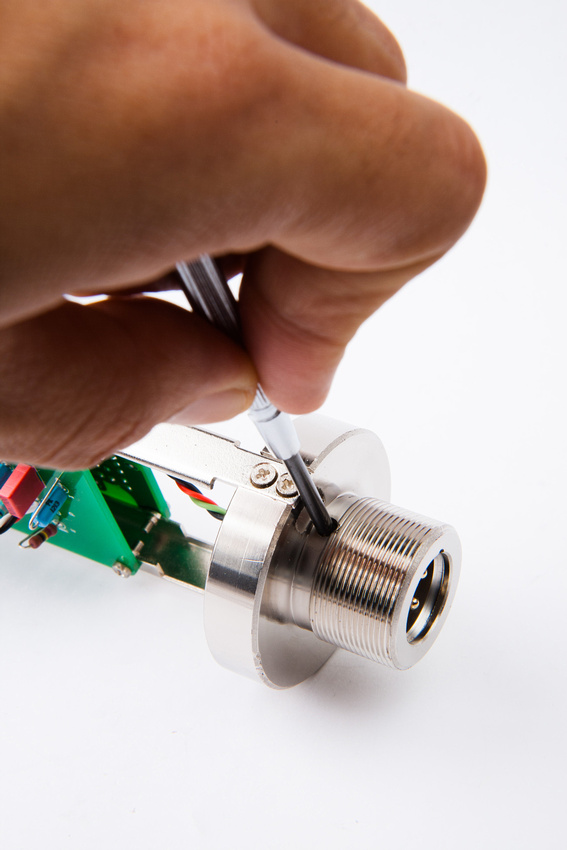

The insert secures to the microphone body via a set screw that presses tightly outward to the body when twisted in the reverse direction.

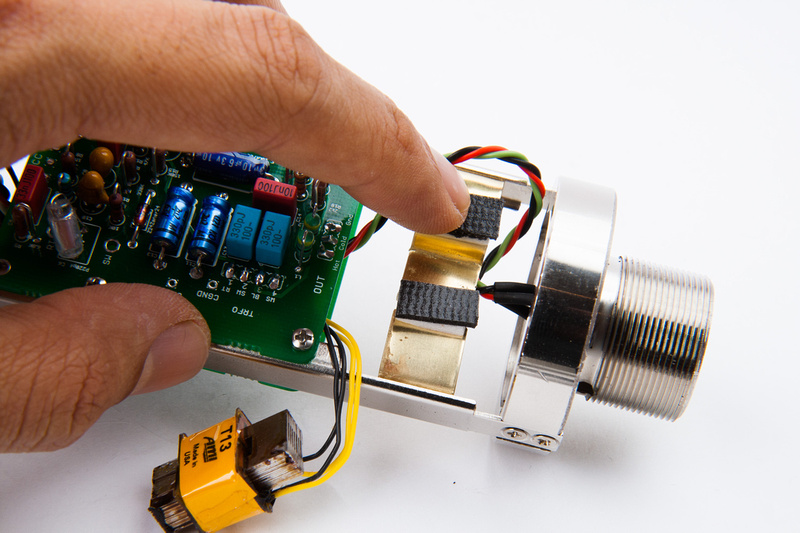

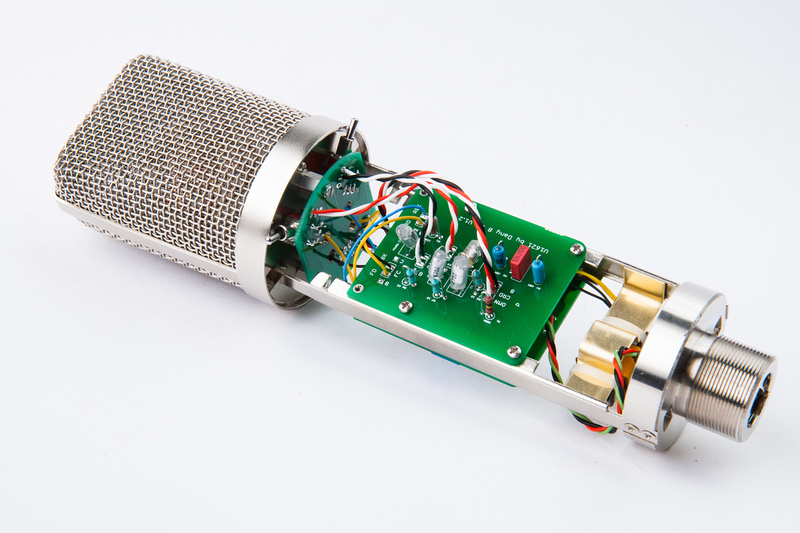

The build could be wired for a cleaner look with a shorter minimum length run of wire, but knowing me, I will have to get back into the PCB to make an adjustment or a correction at some point, so I leave enough slack in the line for future repairs, but not so much that it's overly ugly. . . just borderline-moderate ugly.

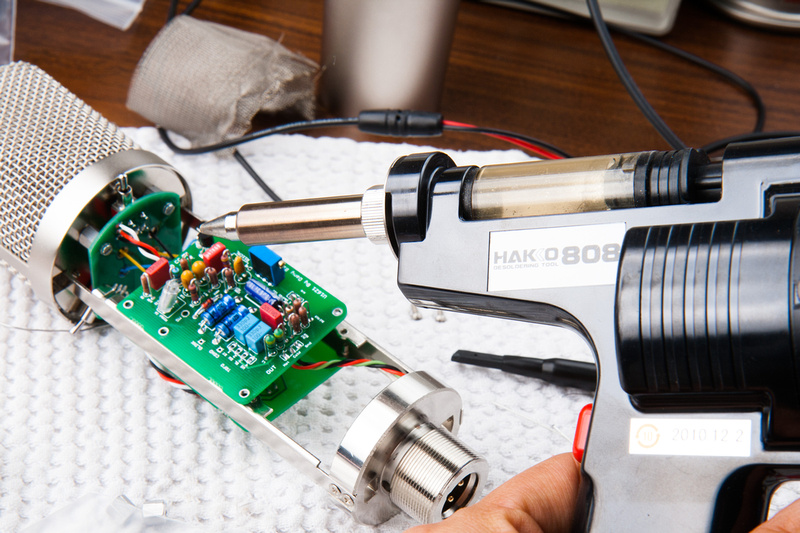

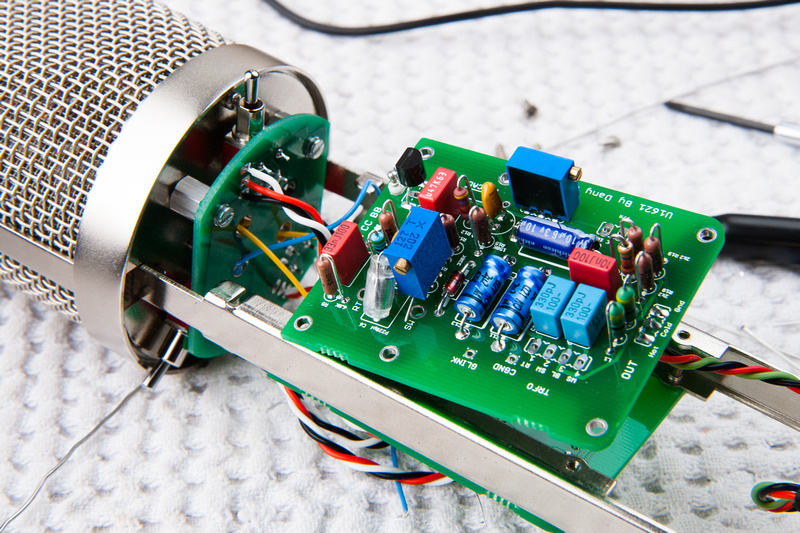

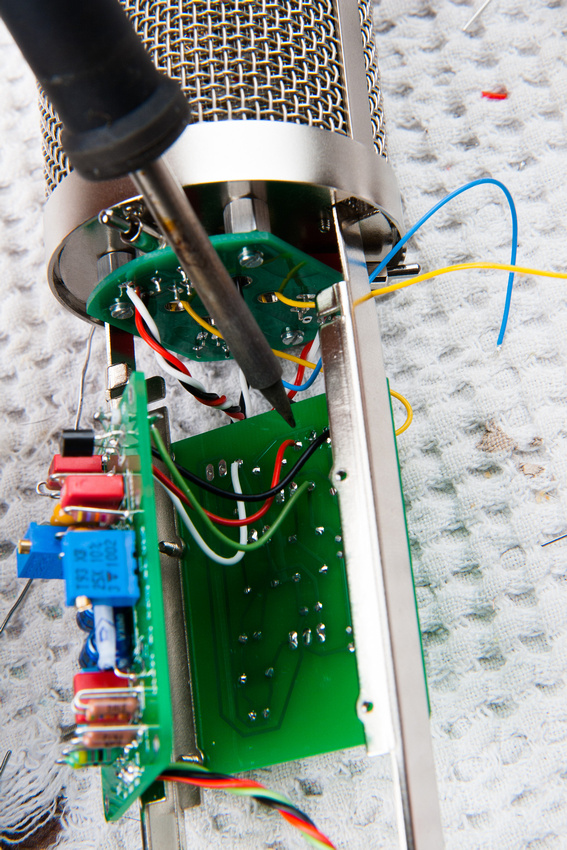

HAa ha!. . . right on cue, the Hakko 808 comes out and I'm swapping components on the pcb. What ended up happening is I made a mistake because I was measuring from the gate instead of the drain with my scope as I tried to bias the FET. Very important to measure from the drain.

My voltages were good at the zener (23.6v) so reading through the thread, I replaced R14 (10K) with a pot. Note, all of this was not necessary because I was silly and measuring from the wrong spot.

But, the extra slack in the xlr cable made repairs and changes much easier.

R14 replaced with a pot set to 10K

I adjusted R14 for a 3V drop across R14 according to the thread.

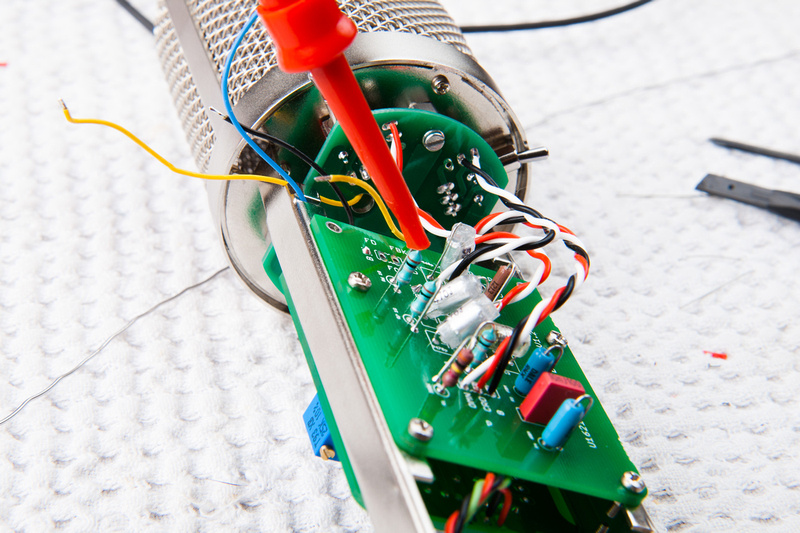

That was when I realized I should go look at the spec sheet for the FET and figure out if I was measuring from the drain, which I wasn't. . . and felt kindof silly. Anyways, here is the correct spot to inject signal (without the capsule connected). The is at R6 which is installed backwards from the silk screening per the build instructions.

And the correct spot to connect the scope.

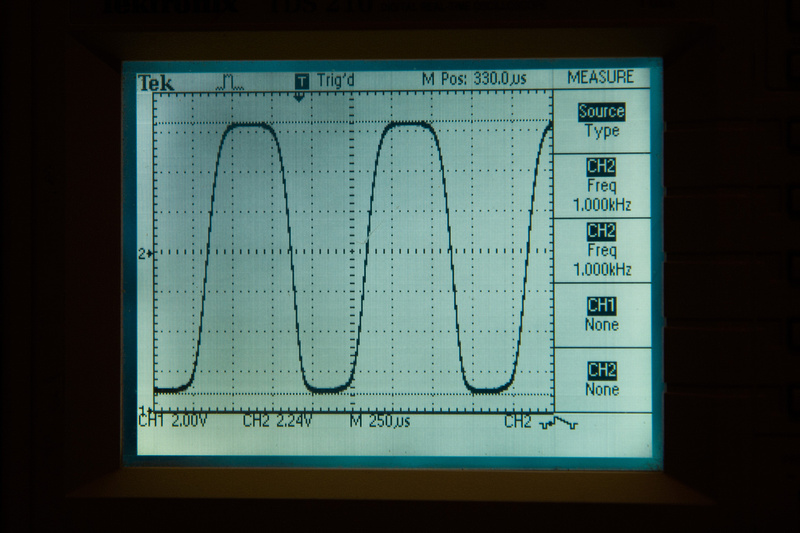

And, measuring from the drain, I was able to adjust the bias pot for symmetrical clipping.

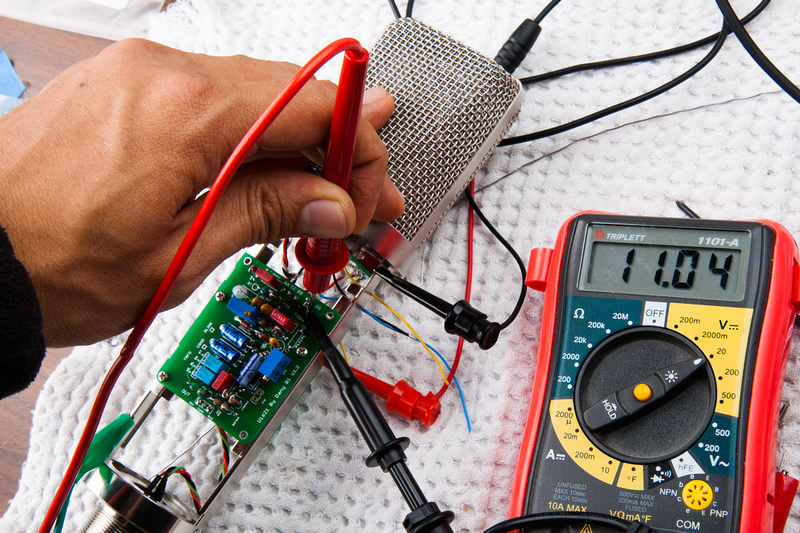

And for this FET in this mic, the drain voltage was 11.04V in this configuration.

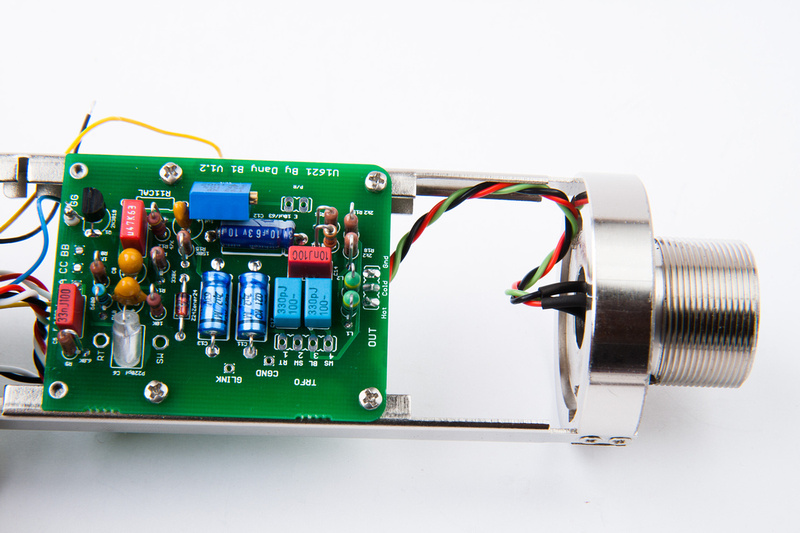

Next, I solder in my capsule connections. When installing the capsule, I was sure to remember where the front and rear connections are.

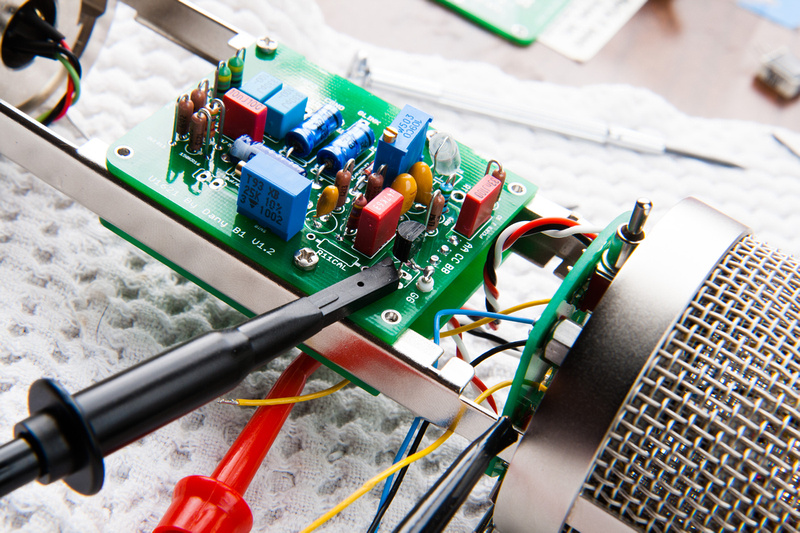

And after some thought, I removed the pot at R14 because the build ended up being pretty solid. I measured its final value at 18K to get a 3V drop across R14. The stock value 10K yielded less of a drop, but I figured why mess with the circuit if it's working as originally spec'd. I had to disconnect the capsule, insert signal again, and re-bias the FET with the original R14 back in, but since I was monkeying around inside the mic already, it wasn't too bad.

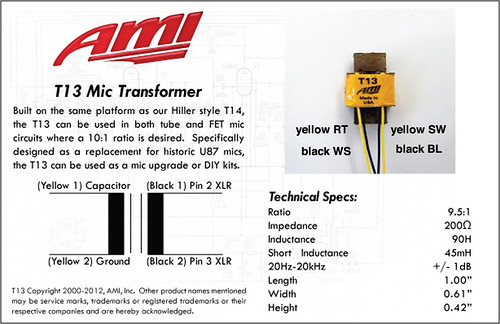

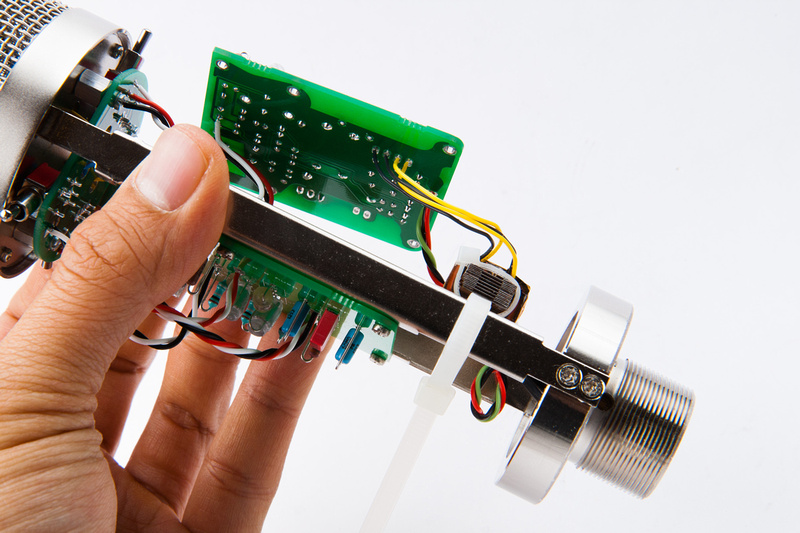

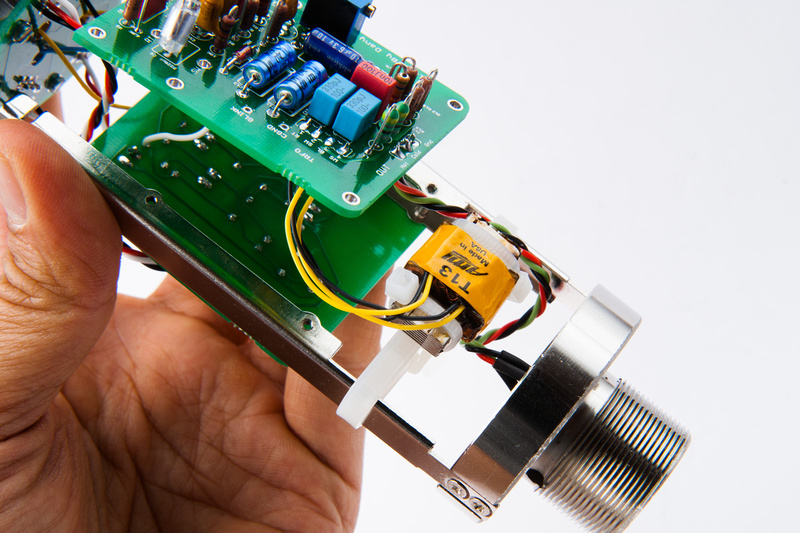

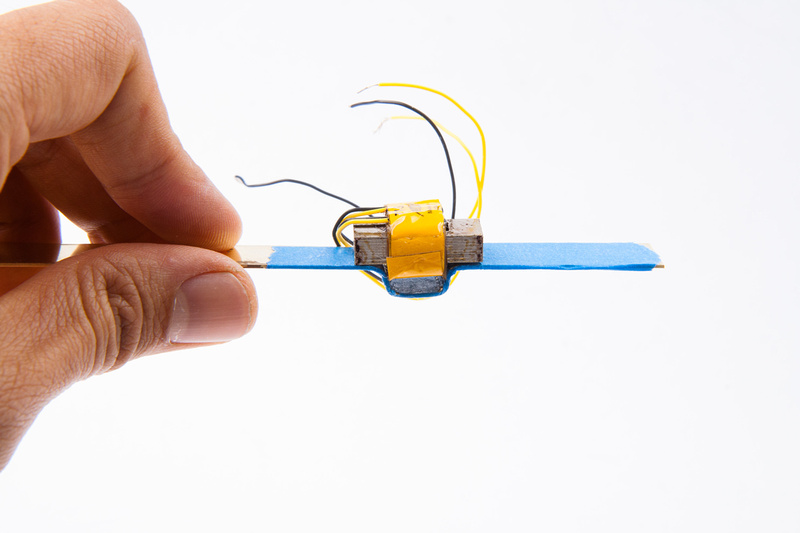

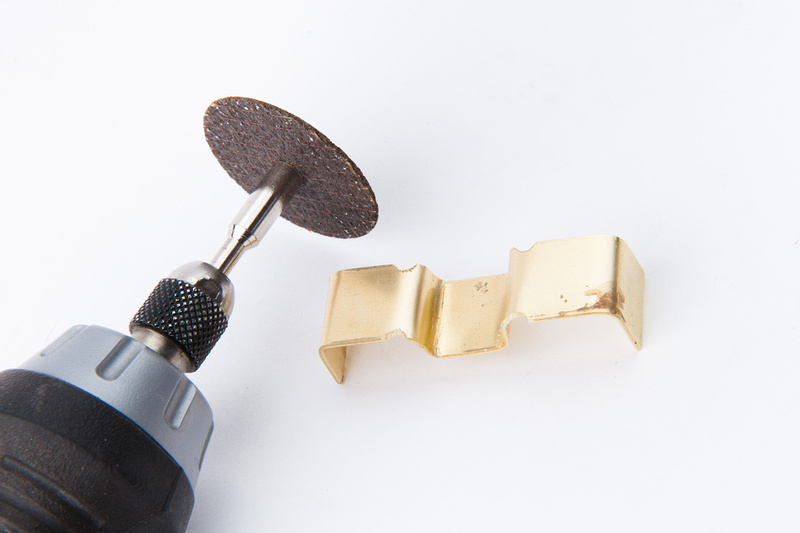

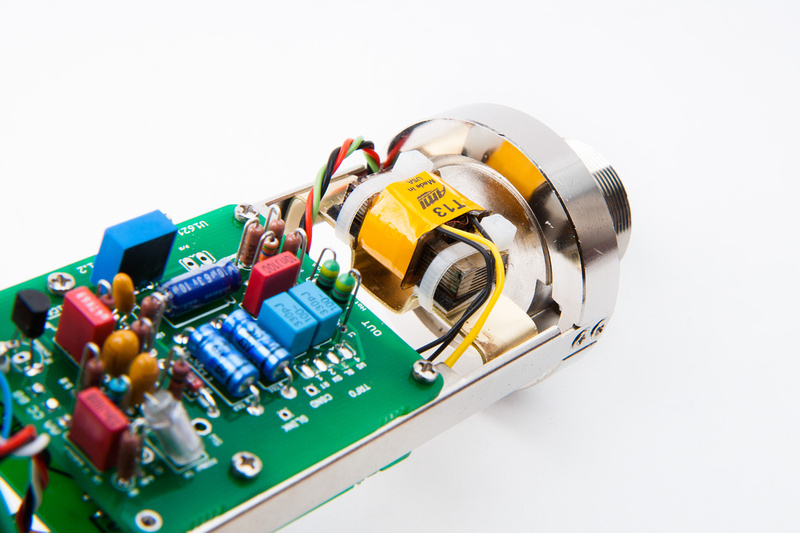

Next, I used some zip ties to attach the T13 transformer. I could not make heads or tails of the silkscreen letter designations, so digging through the official build thread, I came across this image that Wave posted.

Because a large number of T13's were shipped with wire markings reversed from the spec sheet, I checked my transformer and it read about 21R on the yellow side and about 436R on the black side, so mine was reversed. The higher resistance side (yellow in my case) should go towards the capsule side and the lower resistance side (black in my case) should go to the output xlr.

I didn't want to mess up my polarities so I tried following the diagram and reversing the colors since I don't have the foggiest idea what the silk-screened letter indications on the transformer pads mean.

so, with the transformer in the same orientation as the picture:

Left side black --> RT

Left side yellow --> WS

Right side black --> SW

Right side yellow --> BL

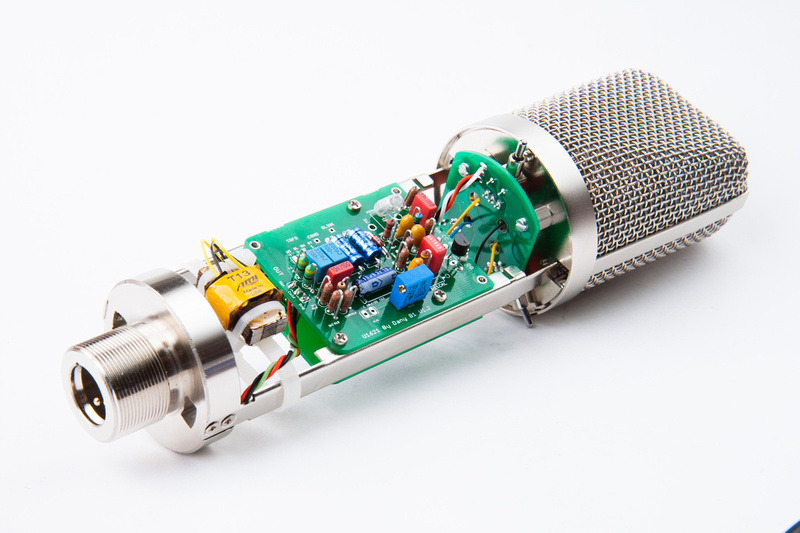

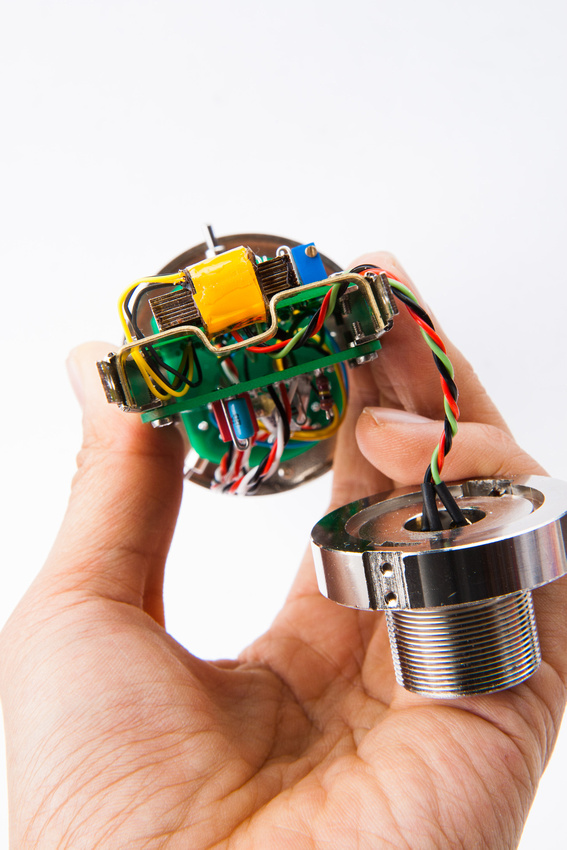

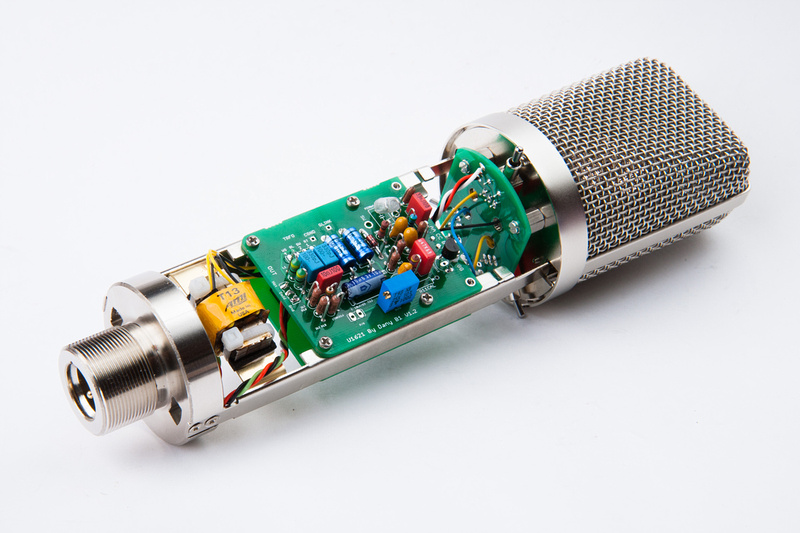

Once the transformer was installed, I proceeded to take beauty shots of the microphone interior because I thought I was done.

. .. and after my nice photo session of my "final" build, I discovered that the tube would not fit over the ziptie that held the transformer in place. . . DOH! And I was so proud of my 3 zip tie solution.