trans4funks1 said:

I'm having a hard time visualizing how a screw that is a few microns long would cause the backplates to touch.

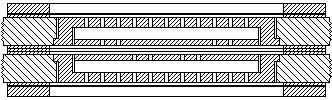

The two capsules are bolted together with 3 screws extending through insulated Perspex back ring holders and a stack of insulated spacer rings. There doesn't seem to be any opportunity for a screw to bridge the brass back plates.

I had written to Beez Neez asking about testing and the matching of the sensitivity and response of the front and back capsules before final assembly. The reply I received indicated that matching is not a matter of testing but rather a matter of perfect machining tolerances.

I was some what surprised at the idea that the QC test procedures aren't significant enough to comment or expound upon.

The idea that a capsule might be shipped internationally and then require a return before an assembly or suitability problem is confirmed is exactly the sort of thing I would hope that QC testing, and front back compatibility selection, would prevent.

I'd sure like to try a Beez Neez ck12 but I'm reluctant to spend $450 on an item that hasn't been specifically tested and confirmed to perform and conform within a range of response that makes its applicability predictable to an end user. I don't have the facility to test the items properly and I don't have the opportunity to compare any item I buy to the rest of the items that were available from the manufacturer. I have to depend on the manufacturer to confirm that the product is representative of the quality that the item is presumed to be.

I understand that over the years there were many very small differences in the brass C12, but it seems as if any particular design, with specific dimensions, should be able to be assembled with consistency and repeatability. It seems like QC testing is the only practical way to assure consistency and justify any reputation for suitability that a product may earn in the marketplace.

I'm hoping this post is received as constructive comment, I have given up an interest in trying a Danish C12. I have read to many observations about the inconsistency and have been put off by the explanations that I have read that the old C12s had varying response so new ones may as well.

I'm hoping that Beez Neez will recognize that there is great value in defining and maintaining a standard for the capsules that they offer.

Hi there.

I'll try to answer your post in the order that you presented it but if it is a bit out, I apologize.

The screw in question was not one of the three that hold the halves together but the screws that hold the centre wires in the backplate. If this screw is even a little over tightened, the internal baffle can be damaged and swell. This swelling of course can't be seen but it can be measured. This swelling or more technically correct if called bruising is what had caused the backplates to touch! It is not a manufacturing defect just and assembly issue.

I wasn't in any way offended as we are all entitled to comment freely here but to say that our QC is "not significant enough to comment or expound upon" is really inaccurate. All of our capsules are scrutinized at least 15 times each during the production phase. I don't usually like to give up too many of our testing procedures but here I feel that it is important as our procedures have been called to question.

We test for;

Inter material machining tolerance.

Acoustic chamber resonance

Acoustic chamber depth tolerance

Side to side capacitance comparison

Capsule capacitance

Diaphragm acoustic resonance

Side to side tolerance

Capsule to capsule tolerance

Contrary to popular belief, there is no black magic super mojo involved in making a microphone capsule. It is quite simply a matter of mathematics and resonances (which is directly and indirectly involved in the mathematics too). If the tolerances are tight, the sound is right!

Please bear in mind that we ship many of these to other manufacturers and customers throughout the globe. Our return rate is less than 2% which we feel is more than acceptable considering the accuracy needed to create these capsules.

Please do not be worried that a capsule is not adequately qc'd to "perform and conform" as we simply. Could not afford the time nor expense of redo's and replacements if they didn't. Our answer is to test test test them until we are satisfied. Each capsule has around two full hours of hands on testing before it leaves our factory.

Each capsule in each batch is carefully matched and carefully measured to exacting tolerances. You are right, there is a definite difference in c12 revisions but this difference is strictly one that is mathematical and measurable not mojoable.

We see a definite benefit in maintaining "a sound" with our ck12 and this is why we are so intent on measuring each capsules attributes so as to maintain consistency. Our capsule may not be as bright as some but it is definitely consistent for response and resonance.

Being called to account on an open forum is not the most comfortable thing to do so I hope this post has been informative enough to set your minds at ease as to our skills and capabilities.

We really love our DIY customers, it is great to see you all experimenting and having fun. Even though the DIY market only represents about 5% of our business, we value it's contribution and it is among one of our favourite parts of our business. Please bear in mind though that if we were to answer in depth like this message, each and every time we are asked similar questions, we would never get off the computer. It's not that we don't perform many levels of QC, we just don't have the time to talk about them constantly.

Thanks for taking the time to read this post. We look forward to helping you int he future.

Ben