granger.frederic said:

It just proves that i've put the finger where it hurts, a painful nerve i have to say!

No, all it really proves is that you've gotten away (again) with dropping in to a thread, posting baseless claims about a product with which you have no direct experience, while proving no direct evidence/explanation that you are right, or even why you are right.

'Respect' is not just about 'tone': it's also about content and intent. Perhaps it's just me, but tone aside, doing this kind of thing just damages the community here, even if done in a 'nice tone'. If I were to drop into a thread, and tell Tim Campbell, "Wow, I hope people aren't going to be sad when their capsules stop working due to the brass alloy you used: Tonval brass was used in AKG's original and really is the only thing that will hold up over time...", could I expect to get a pass since I used a 'nice tone', or would I be expected to justify my words? BTW all of that was completely made up, but it sure sounded good, didn't it? Would we expect Tim to have to deconstruct original capsules, perform metallurgical analysis on his parts versus an original, and then show accelerated aging studies? Just to disprove a negative?

As Chunger has said, we've been through 4 revisions on this project over the past few years, and 90% of the changes were directly from people direct experiences with either a) the build process itself, or b) the performance measured in real situations. I've had countless people PM me with stuff like "Hey, I didn't want to cause trouble in case I'm wrong, but here is what I observed...", to which I answered "You totally should put that in the thread, because I bet others are wondering the same thing, or might experience this and wonder what caused it." I don't even expect people to do this as a habit, but it's always nice to see people go an extra step here and that's what makes it a great place.

I've generally gone out of my way to contribute in other's projects if I have something helpful to offer, or have experience that explains why something is the way that it is. I wrote a JFET source resistance calculator for Poctop's U87 project, and I've never seen a single dime from that project. I've gone to great lengths explaining tube biasing to many here. So you don't get a pass dismissing what I say with quotes about "protecting business interests". If you think I'm wrong, then prove it to me.

There's nothing wrong with asking questions or debating theories, but it has to be exactly that: a question or a theory. I find it hard to believe that you think it's a personal vendetta about your opinion, when you started off the entire process by morphing your opinion into a fact about someone else's product. And this thread is not the first time.

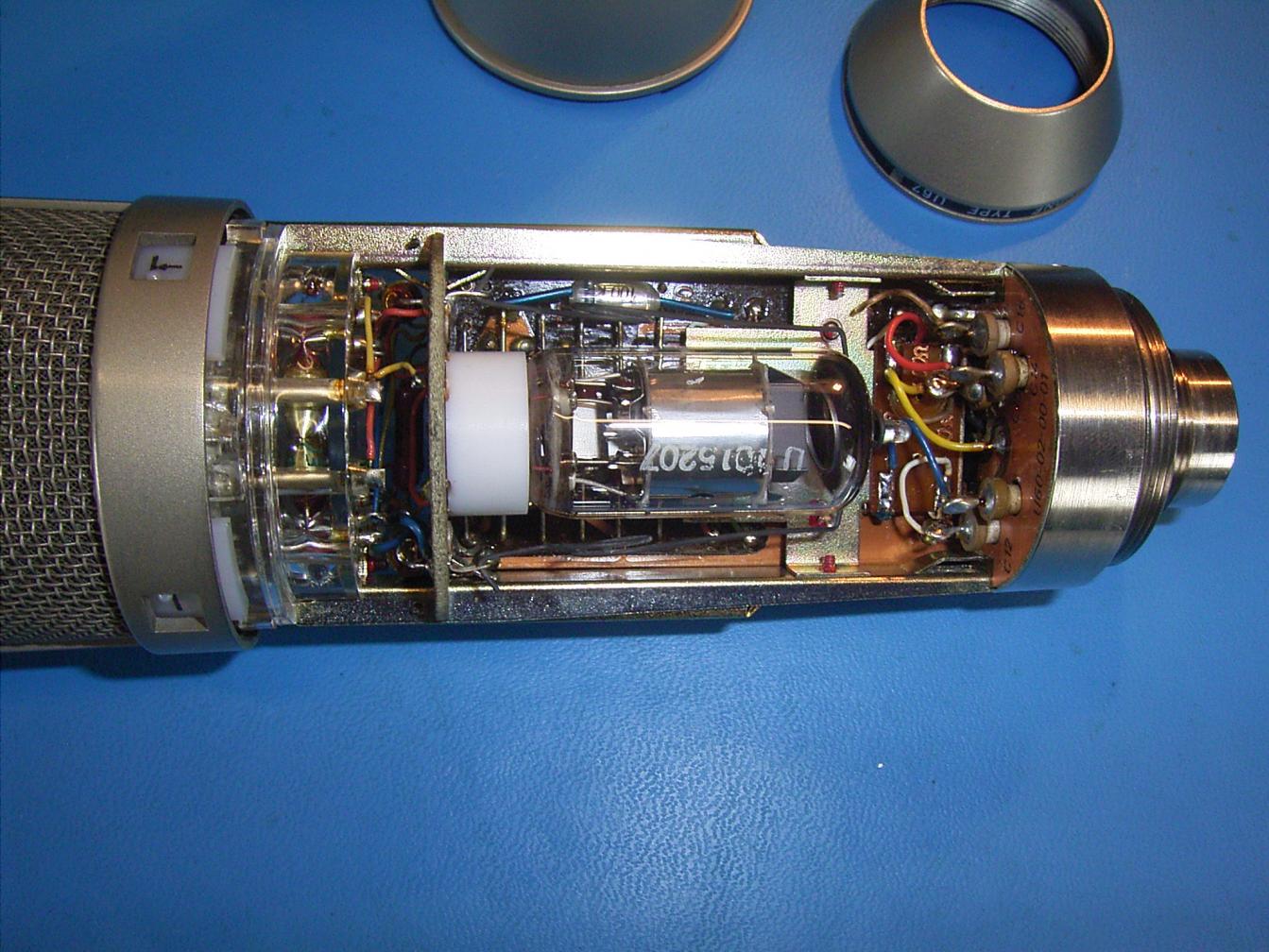

I'll end with this: next time, try this out for size: "Hey, I notice that the high impedance nodes are on the PCB rather than floating: was that a deliberate design decision? Did you notice any mechanical issues during prototype stages? Hey, did you change that material because you were concerned about moisture problems?" That would have initiated a dialog, rather than just asserting something is true, and that others must be in the wrong for questioning it, and that any conceivable response can be immediately dismissed in the interest of 'protecting business interests".